Nano-metal antibacterial fiber fabric and production method thereof

A technology of antibacterial fiber and nano-metal, applied in the direction of fiber type, fiber treatment, biochemical fiber treatment, etc., can solve the problems of antibacterial effect decline, smell overflow, affect hygiene, etc., and achieve the effect of avoiding human body odor overflow and strong antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments.

[0035] The nanometer metal antibacterial fiber fabric of the present invention comprises a surface layer and an inner layer sequentially from top to bottom, and the surface layer and the inner layer are connected by a weft bonding tissue;

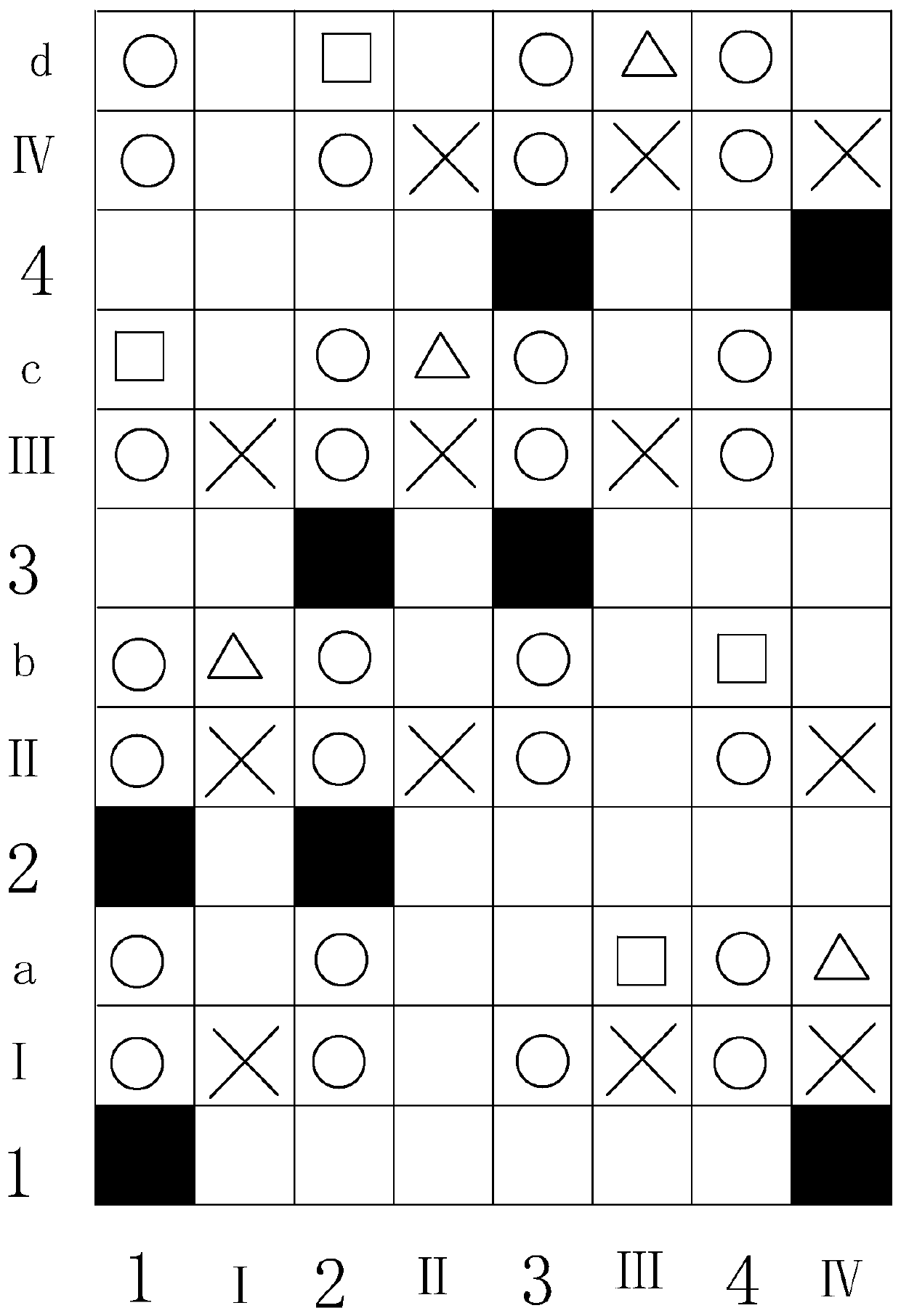

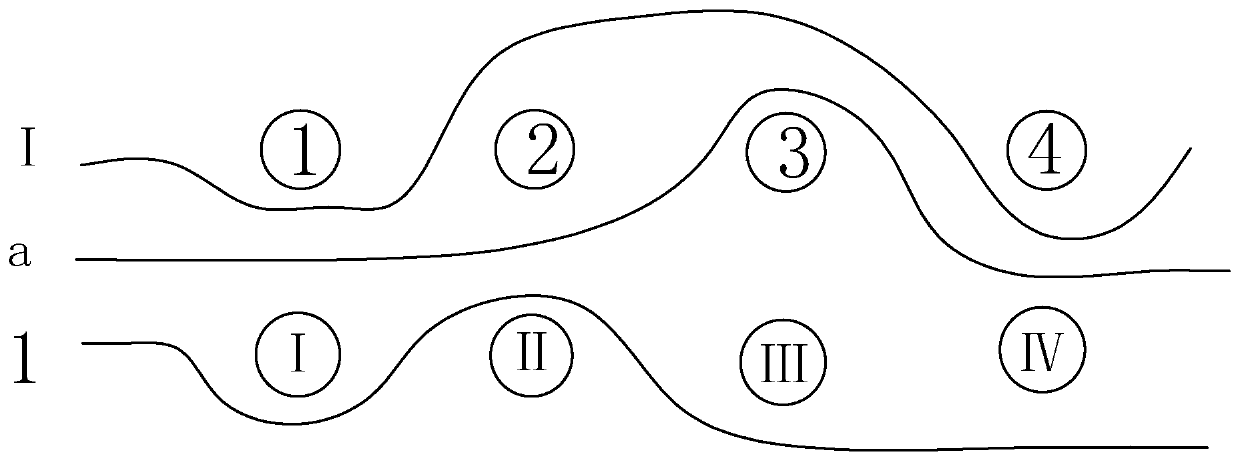

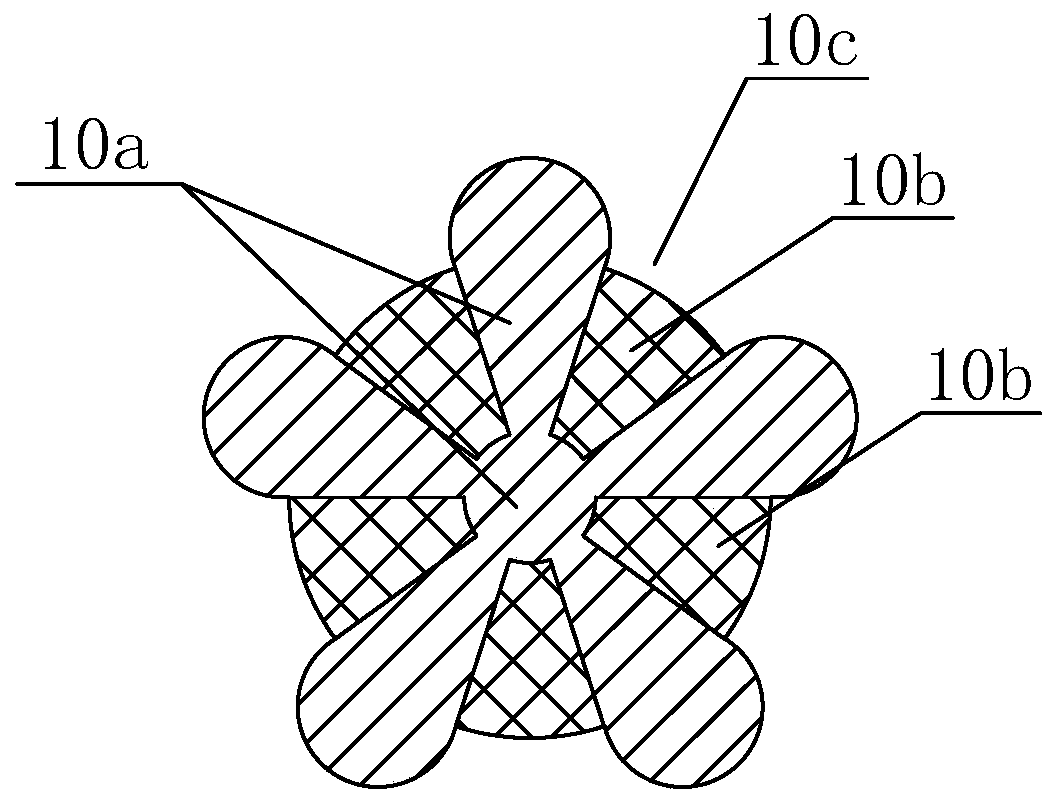

[0036] The surface weave of the surface layer is a two-up, two-down right twill weave, and the inner weave of the inner layer is a three-up, one-down right twill weave. as attached figure 1 In the organizational chart shown, Arabic numerals are used to mark the surface warp and surface weft, Roman numerals are used to mark the inner warp and inner weft, and letters are used to indicate the binding weft. The double-layer fabric is made of two sets of warp yarns and three sets of weft yarns. It is interwoven with both the surface warp and the interior warp. Mark the organization symbol "■" at the intersection of the surface warp and surface weft, mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com