High-tenacity antibacterial plastic and preparation process thereof

An antibacterial plastic and high toughness technology, applied in the field of plastics, can solve the problems of poor heat resistance, poor durability, easy leakage, etc., and achieve the effects of good safety, good antibacterial ability, excellent mechanical properties and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

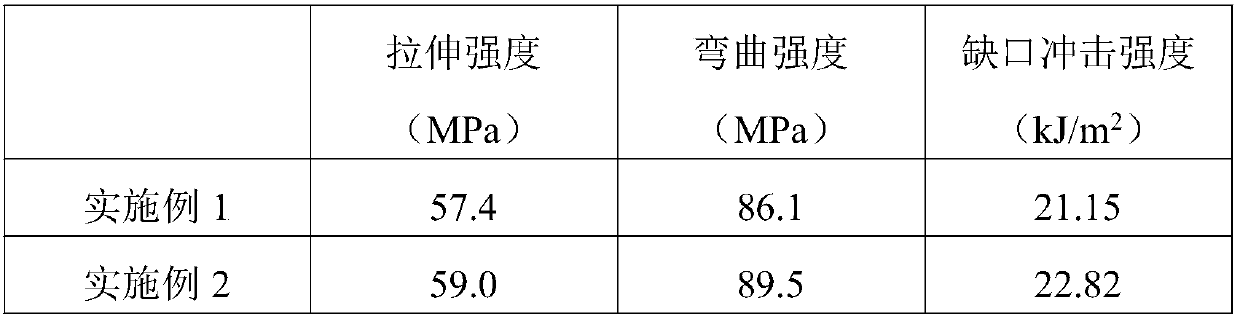

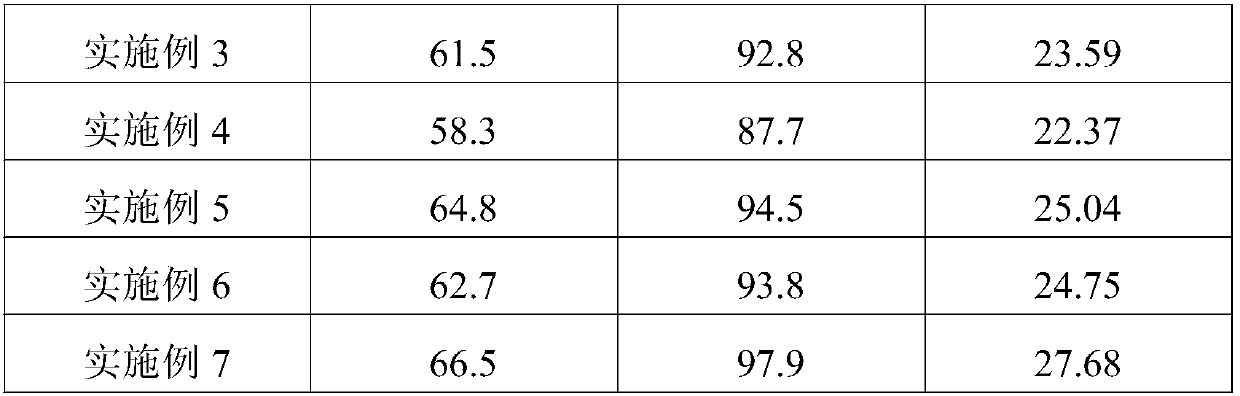

Examples

Embodiment 1

[0034] Embodiment 1 high-toughness antibacterial plastic and its preparation

[0035] The formula of high-toughness antibacterial plastics: 40 parts by weight of polyphenylene ether, 80 parts by weight of polystyrene, 1 part by weight of silver nanoparticles modified by oleic acid and n-propylamine, methacrylate-butadiene-styrene core-shell structure copolymerization 20 parts by weight.

[0036] The preparation technology of high-toughness antibacterial plastic comprises the following steps:

[0037] (1) Dry the raw materials at 75°C for 10 hours;

[0038] (2) Weigh the dried raw materials according to the formula, stir and mix in a high-speed mixer at 70°C at a speed of 400 rpm for 10 minutes, and extrude and granulate in a twin-screw extruder after mixing, wherein the extruder The temperature from the feeding section to the die is: 25°C, 230°C, 240°C, 240°C, 240°C, 250°C, 250°C, 250°C, 240°C, the speed is 180 rpm, the mixture is heated and melted into a molten The body, d...

Embodiment 2

[0040] Embodiment 2 high tenacity antibacterial plastics and its preparation

[0041] The formula of high-toughness antibacterial plastics: 40 parts by weight of polyphenylene ether, 80 parts by weight of polystyrene, 1 part by weight of silver nanoparticles modified by oleic acid and n-propylamine, styrene-(ethylene-butylene)- 20 parts by weight of styrene block copolymer.

[0042] The preparation technology of high-toughness antibacterial plastic comprises the following steps:

[0043] (1) Dry the raw materials at 75°C for 10 hours;

[0044] (2) Weigh the dried raw materials according to the formula, stir and mix in a high-speed mixer at 70°C at a speed of 400 rpm for 10 minutes, and extrude and granulate in a twin-screw extruder after mixing, wherein the extruder The temperature from the feeding section to the die is: 25°C, 230°C, 240°C, 240°C, 240°C, 250°C, 250°C, 250°C, 240°C, the speed is 180 rpm, the mixture is heated and melted into a molten The body, driven by the sc...

Embodiment 3

[0047] Embodiment 3 high-toughness antibacterial plastics and preparation thereof

[0048] The formula of high-toughness antibacterial plastics: 40 parts by weight of polyphenylene ether, 80 parts by weight of polystyrene, 1 part by weight of silver nanoparticles modified by oleic acid and n-propylamine, methacrylate-butadiene-benzene modified by maleic anhydride 20 parts by weight of ethylene core-shell structure copolymer.

[0049] The preparation technology of high-toughness antibacterial plastic comprises the following steps:

[0050] (1) Dry the raw materials at 75°C for 10 hours;

[0051] (2) Weigh the dried raw materials according to the formula, stir and mix in a high-speed mixer at 70°C at a speed of 400 rpm for 10 minutes, and extrude and granulate in a twin-screw extruder after mixing, wherein the extruder The temperature from the feeding section to the die is: 25°C, 230°C, 240°C, 240°C, 240°C, 250°C, 250°C, 250°C, 240°C, the speed is 180 rpm, the mixture is heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com