Method for directly preparing aluminum alloy refiner through waste aluminum recycle

A refiner, aluminum alloy technology, applied in the direction of improving process efficiency, can solve the problems of refinement effect decline, particle aggregation, etc., to achieve the effect of reasonable equipment structure, reduction of production and emission, and reduction of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

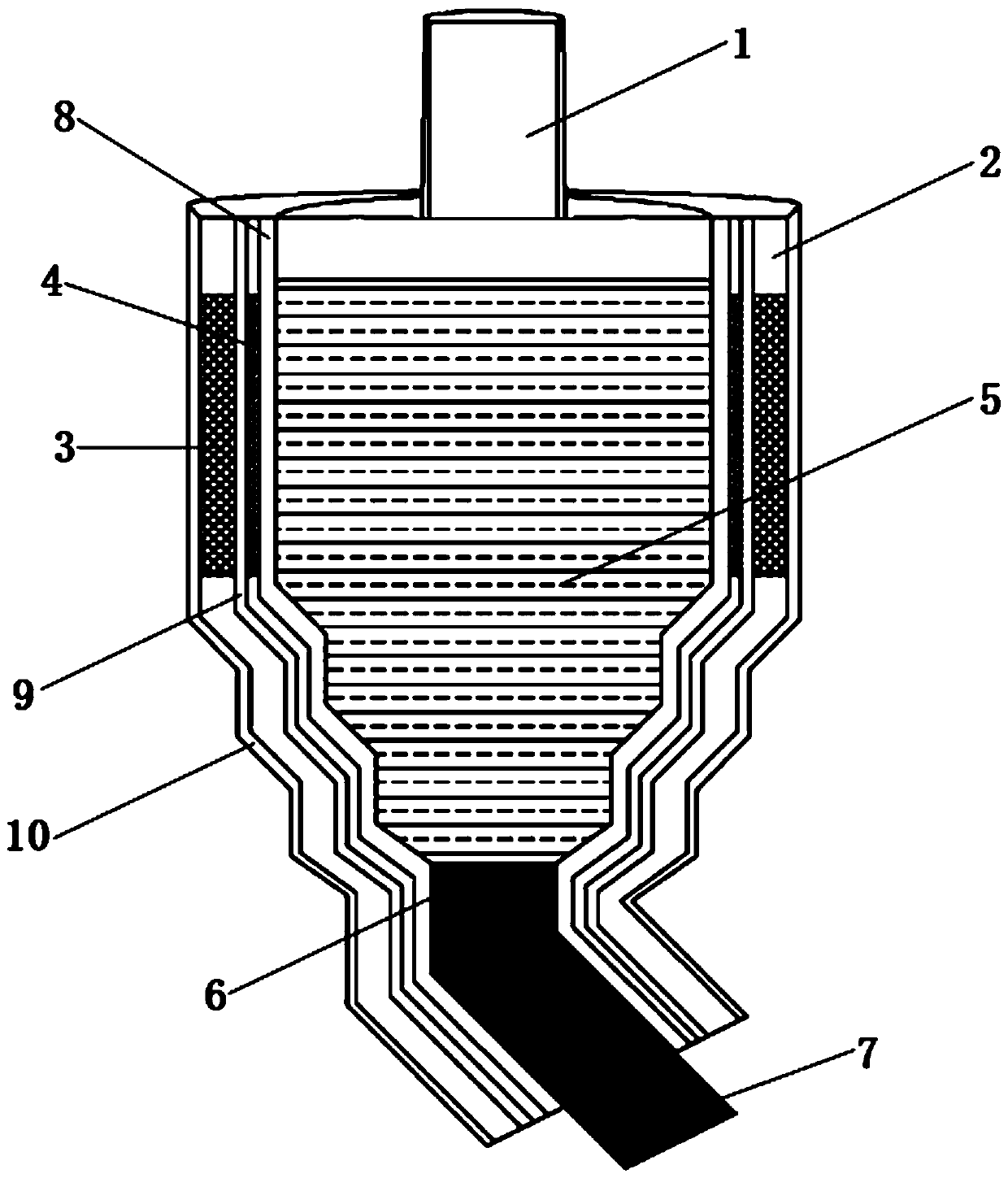

Image

Examples

Embodiment 1

[0036] The method for directly preparing the aluminum alloy refiner from waste aluminum recycling in this embodiment comprises the following steps:

[0037] 1) Aluminum scrap pretreatment: Electromagnetic iron removal, acetone immersion degreasing and water washing are performed on the waste aluminum, and then the modified liquid is sprayed, and the waste aluminum is crushed into aluminum chips with a particle size of 2-8cm by a crusher; after the above crushing Add the aluminum chips into the paint removal solution, and place them in 40°C for full soaking treatment for 30 minutes; immerse the above-mentioned aluminum chips after depainting in the cleaning solution and ultrasonically clean them for 40 minutes to remove the oxide film on the surface of the aluminum chips; put the above-mentioned aluminum chips after removing the oxide film Use a rotary dryer to dry, the drying rotation speed is 2r / min, the hot air speed is 1m / s, the hot air temperature is 60°C, and the drying ti...

Embodiment 2

[0046] The method for directly preparing the aluminum alloy refiner from waste aluminum recycling in this embodiment comprises the following steps:

[0047] 1) Aluminum scrap pretreatment: Electromagnetic iron removal, acetone immersion degreasing and water washing are performed on the waste aluminum, and then the modified liquid is sprayed, and the waste aluminum is crushed into aluminum chips with a particle size of 2-8cm by a crusher; after the above crushing Add the aluminum chips into the paint removal solution, and place them in 50°C for full immersion treatment for 40 minutes; immerse the above-mentioned aluminum chips after depainting in the cleaning solution and ultrasonically clean them for 50 minutes to remove the oxide film on the surface of the aluminum chips; put the above-mentioned aluminum chips after removing the oxide film Use a rotary dryer to dry, the drying rotation speed is 4r / min, the hot air speed is 1.5m / s, the hot air temperature is 80°C, and the dryin...

Embodiment 3

[0055] The method for directly preparing the aluminum alloy refiner from waste aluminum recycling in this embodiment comprises the following steps:

[0056] 1) Aluminum scrap pretreatment: Electromagnetic iron removal, acetone immersion degreasing and water washing are performed on the waste aluminum, and then the modified liquid is sprayed, and the waste aluminum is crushed into aluminum chips with a particle size of 2-8cm by a crusher; after the above crushing Add the aluminum chips into the paint removal solution, and place them in 60°C for 50 minutes of full immersion treatment; immerse the above-mentioned aluminum chips after depainting in the cleaning solution and ultrasonically clean them for 60 minutes to remove the oxide film on the surface of the aluminum chips; put the above-mentioned aluminum chips after removing the oxide film Use a rotary dryer to dry, the drying rotation speed is 6r / min, the hot air speed is 2m / s, the hot air temperature is 100°C, and the drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com