Environmentally-friendly high-permeability modified epoxy rusty coating

A high-permeability, environmentally friendly technology, applied in the field of coatings, can solve the problem of reducing the adhesion performance of the coating film, the mechanical properties of the non-corroded steel, the rust-proof function, the reduction of the adhesion of the paint film, the mechanical properties and the anti-corrosion performance, the flammability Explosive construction safety and other issues, to achieve the effect of small curing shrinkage, improved flexibility and adhesive properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An embodiment of the environment-friendly high-permeability modified epoxy rust coating of the present invention, the coating is composed of component A and component B in a weight ratio of component A: component B=100:17;

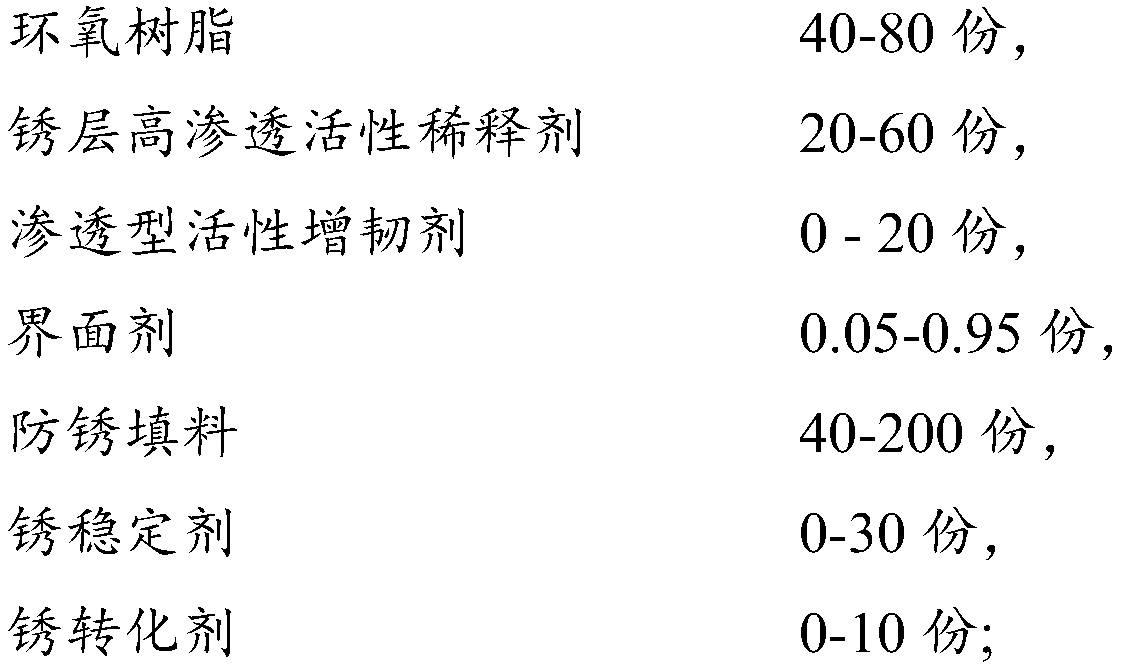

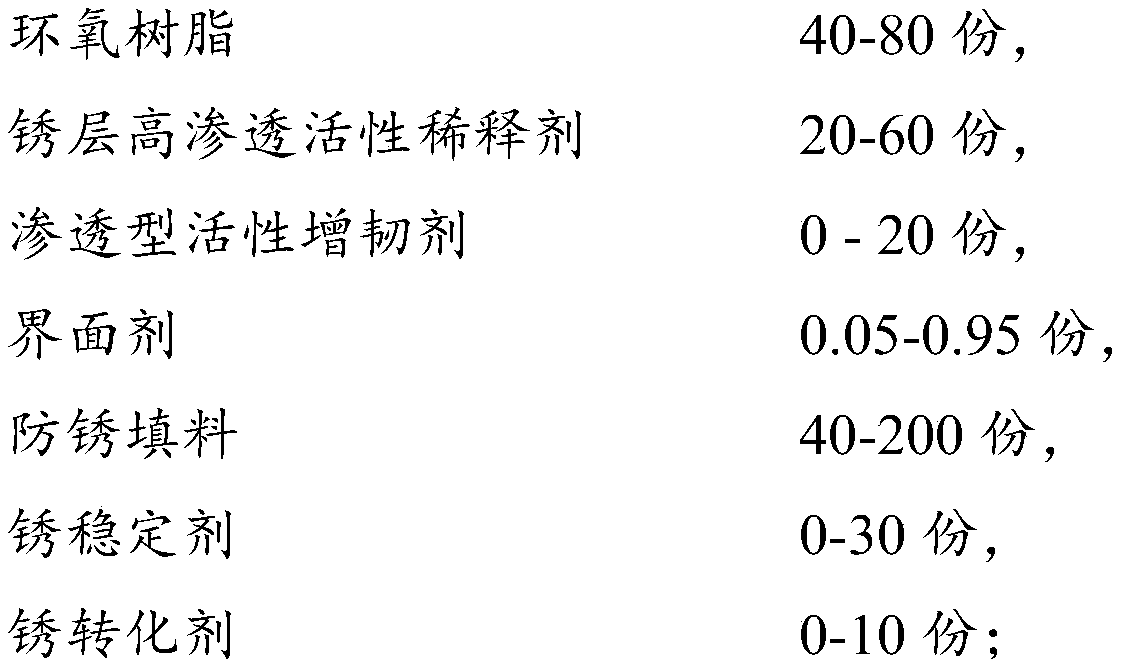

[0040] Wherein the first component is made up of the composition of following weight part:

[0041]

[0042] B component comprises the composition of following weight part:

[0043]Amine curing agent 593 (amine curing agent) 15 parts,

[0044] ketimine (moisture consumption functional curing agent) 17.5 parts,

[0045] 1 part of DMP-30 (curing accelerator);

[0046] The rust converting agent is at least one of phosphoric acid, ferrocyanide, salicylic acid, chromic acid, oxalic acid and tannic acid.

Embodiment 2

[0048] An embodiment of the environment-friendly high-permeability modified epoxy rust coating of the present invention, the coating is composed of component A and component B in a weight ratio of component A: component B=100:3;

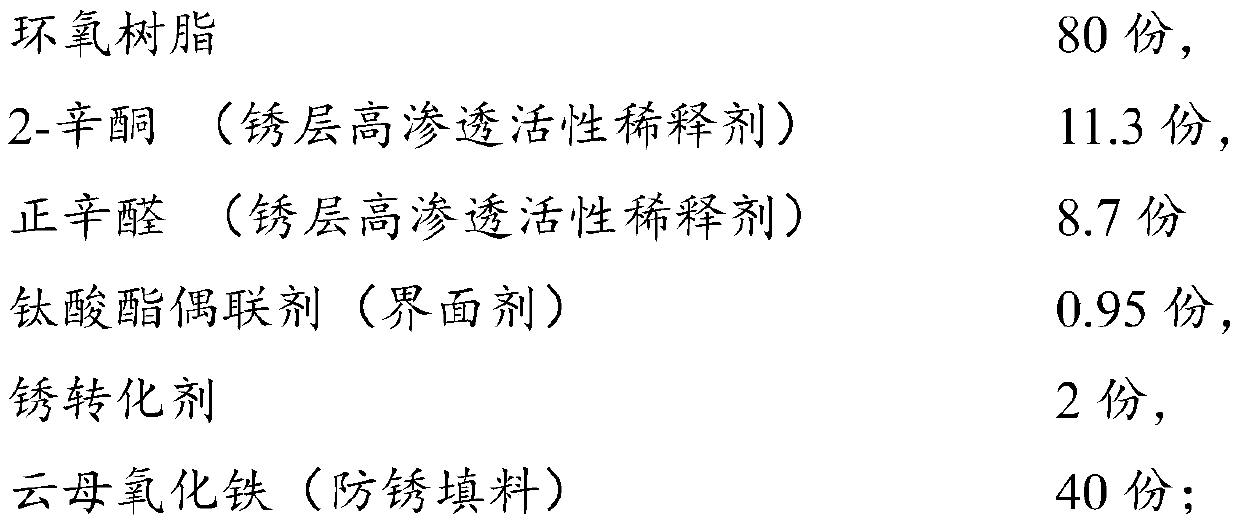

[0049] Wherein the first component is made up of the composition of following weight part:

[0050]

[0051] B component comprises the composition of following weight part:

[0052] Diethylenetriamine (amine curing agent) 41.5 parts,

[0053] ketimine (moisture consumption functional curing agent) 10 parts,

[0054] DMP-30 (accelerator) 10 parts;

[0055] The rust stabilizer is at least one of chromate, phosphate, tetrabasic zinc yellow, diphenylguanidine chromate, triphenylguanidine chromate, ferrite and organic nitrogen base.

Embodiment 3

[0057] An embodiment of the environment-friendly high-permeability modified epoxy rust coating of the present invention, the coating is composed of component A and component B with a weight ratio of component A: component B=100:5;

[0058] Wherein the first component is made up of the composition of following weight part:

[0059]

[0060] B component comprises the composition of following weight part:

[0061] Amine curing agent 810 (amine curing agent) 3 parts,

[0062] ketimine (moisture consumption functional curing agent) 5 parts,

[0063] 3 parts of benzyldimethylamine (curing accelerator);

[0064] The rust stabilizer is at least one of chromate, phosphate, tetrabasic zinc yellow, diphenylguanidine chromate, triphenylguanidine chromate, ferrite and organic nitrogen base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com