Real-time chemical corrosion device and method for impact testing

A technology of impact test and chemical corrosion, applied in impact test, measuring device, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of reducing test accuracy, not conforming to engineering practice, long time, etc., to improve test accuracy stability, improve accuracy, and reduce the effect of reaction volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be briefly described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other implementations obtained by those skilled in the art without creative work Examples, all belong to the protection scope of the present invention.

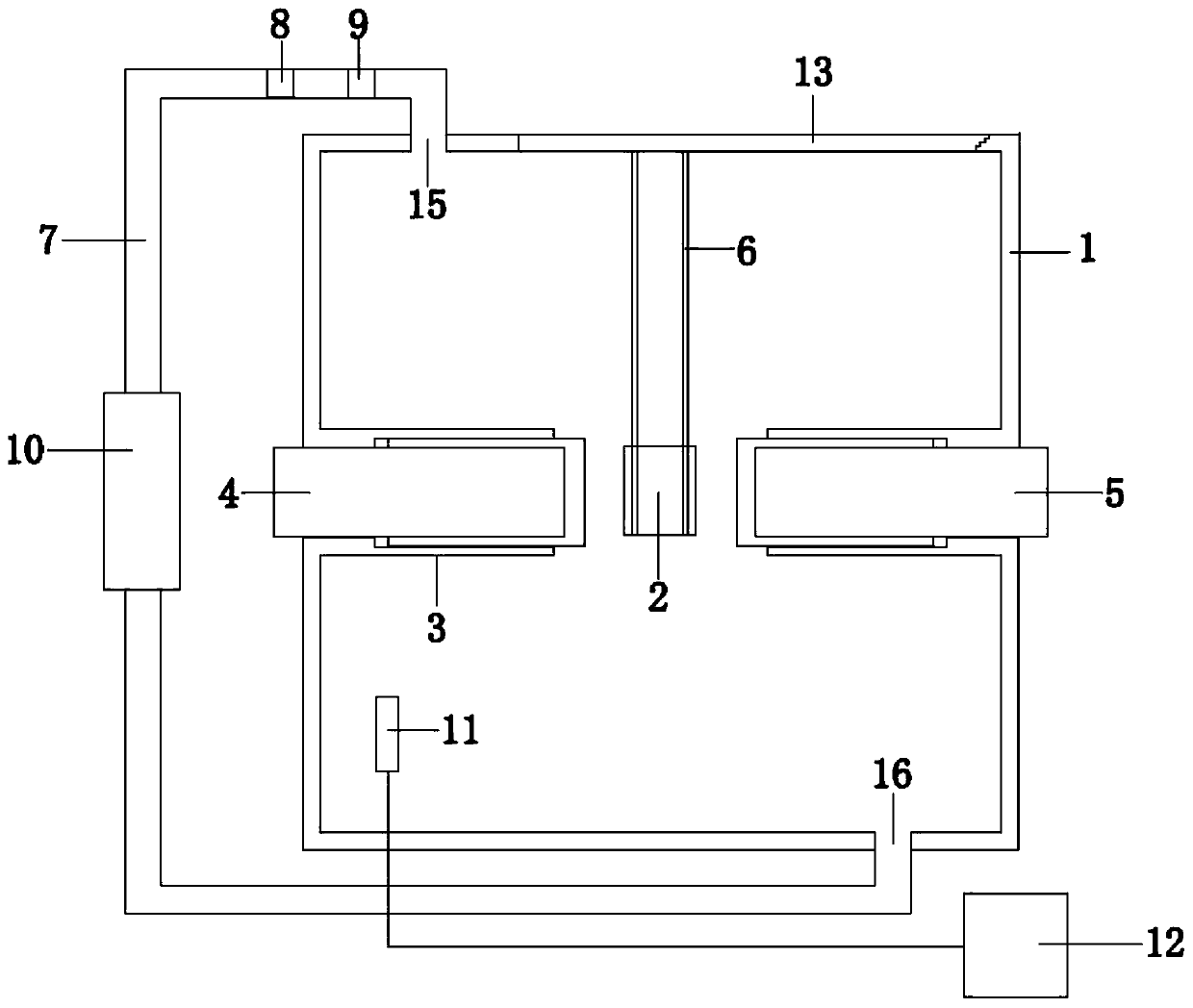

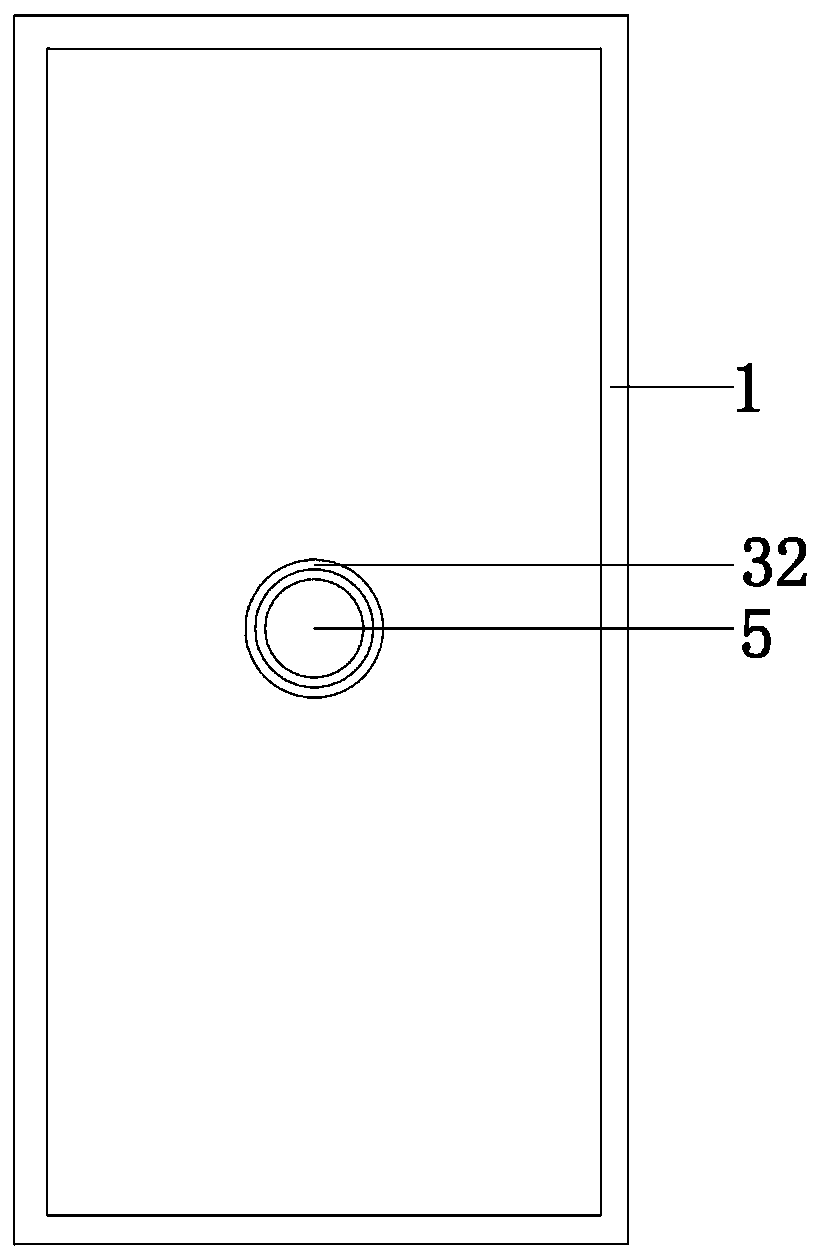

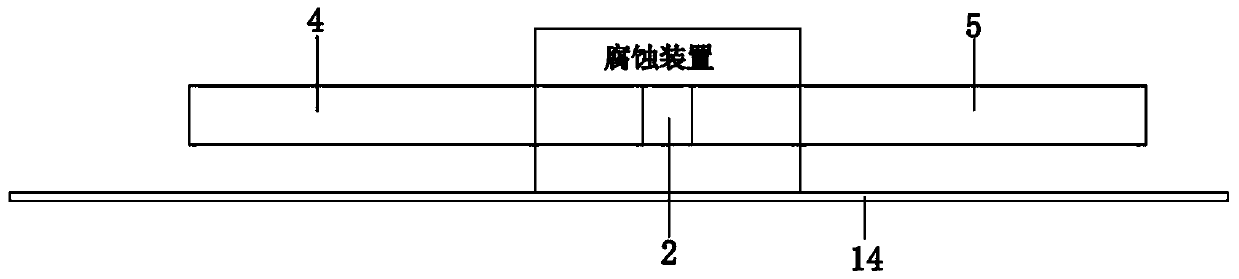

[0034] Figure 1-Figure 4 The preferred embodiment of the present invention is shown, and it is analyzed in detail from different angles.

[0035] Such as Figure 1-4 A real-time chemical corrosion device for impact test is shown, including a water tank 1 with a cover for containing the corrosion solution and a sample 2 placed in the water tank 1, and two symmetrically placed on the water tank 1 for placing the impact The accommodating cavity 3 of the incident rod 4 and the transmission rod 5 required for the test. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com