Dustproof drying device for textile processing

A drying device and dust-proof technology, applied in the field of textile processing, can solve the problems of dust, detachment, and harm to the working environment, etc., and achieve the effects of improving drying rate, improving dust-absorbing ability, and preventing clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

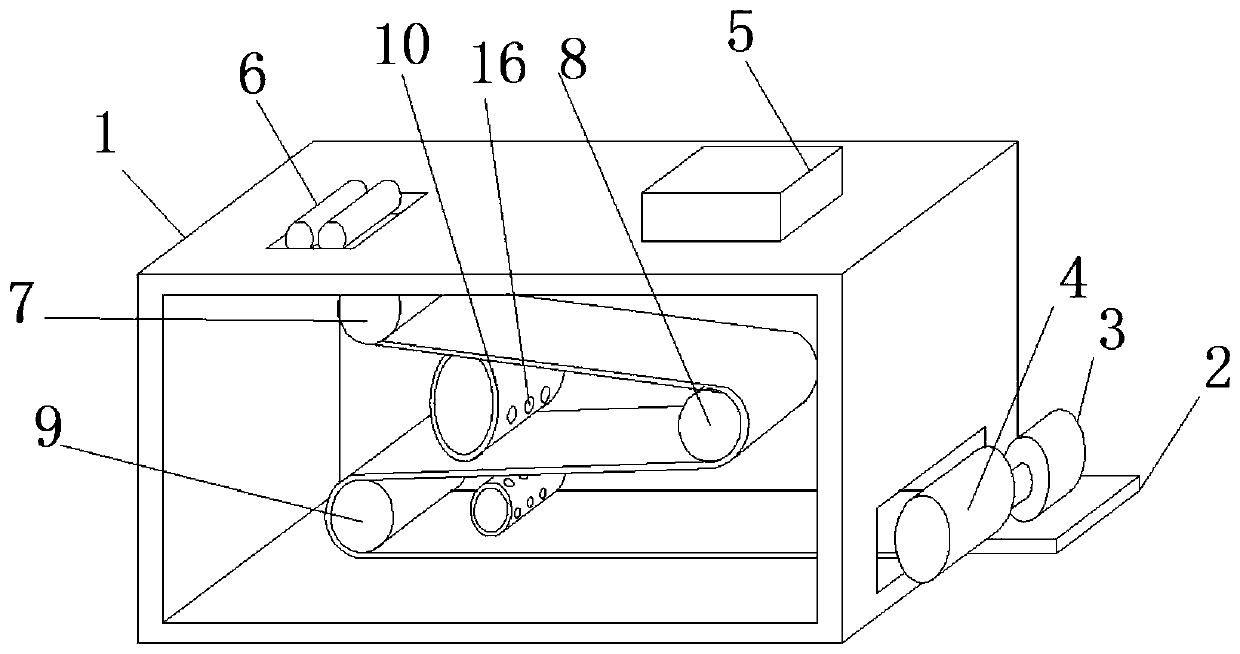

[0027] refer to Figure 1-2 , a dust-proof drying device for textile processing, comprising a box body 1, two circular through holes are opened on one side of the inner wall of the box body 1, and a dust collection box 11 is welded at the circular through holes of the box body 1 One end of the dust collection box 11 is welded with the external negative pressure fan system, the two sides of the top of the dust collection box 11 are welded with support rods 14, one end of the dust collection box 11 is welded with a dust collection cylinder 10 outside, and the dust collection box 11 is welded to the outside. The outside of the dust cylinder 10 is provided with several suction holes 16, the top of the pole 14 is provided with a drum 12, and the bottom of the drum 12 is provided with a sliding groove, and the drum 12 and the pole 14 are slidably connected at the sliding groove , the exterior of the drum 12 is provided with several through holes, the exterior of the drum 12 is welde...

Embodiment 2

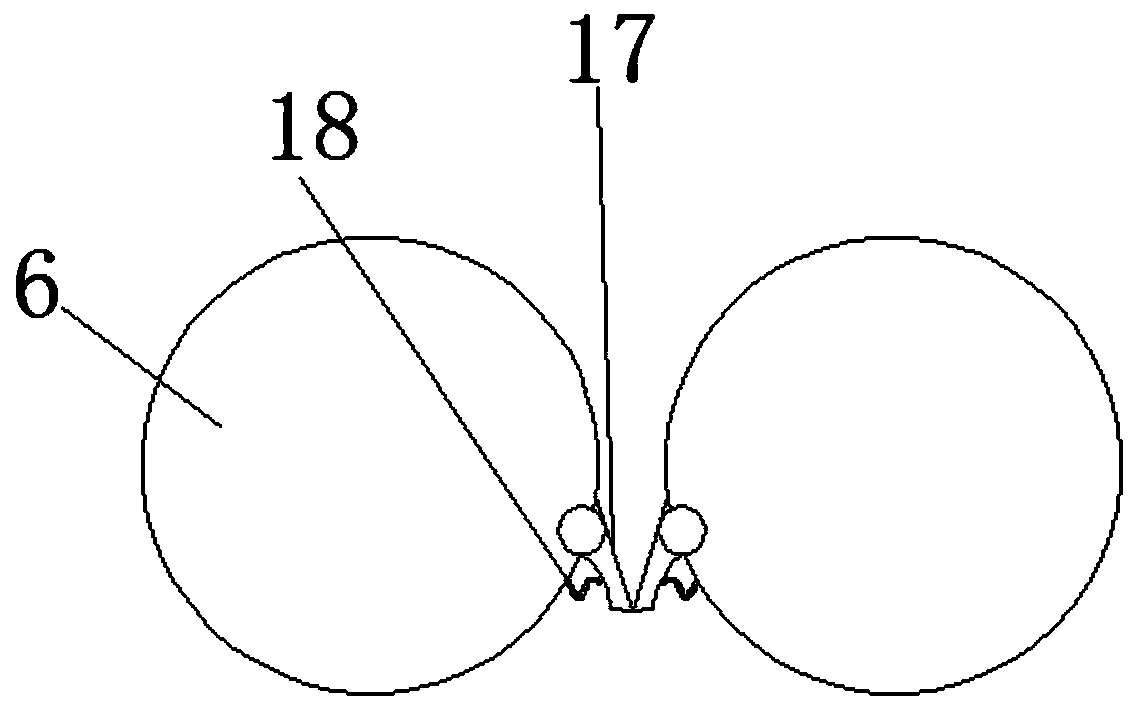

[0032] refer to image 3 , a dust-proof drying device for textile processing. Compared with Embodiment 1, this embodiment is in order to prevent the textile from being damaged due to the influence of friction between the extrusion rod and the extrusion rod when it is squeezed. 6 is welded with an arc-shaped scraper 17, and one side of the arc-shaped scraper 17 is rotationally connected with the extruding rod 6. A spring 18 is welded between the arc-shaped scraper 17 and the extruding rod 6. When the textile is extruded When working, the contact area between the two scrapers 17 and the textiles becomes smaller, which increases the pressure received by the textiles and makes it easier for the water to be squeezed out. In addition, the elastic limit of the spring 18 prevents the textiles from contacting the extrusion rod The friction between 6 is too large, which may lead to the occurrence of textile damage.

[0033]Working principle: Turn on the DMJ-30 type hot air blower 5 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com