Fe-Mn-Al-Ni-Nb shape memory alloy and preparation method thereof

A fe-mn-al-ni-nb, memory alloy technology, applied in the field of Fe-Mn-Al-Ni-Nb shape memory alloy and its preparation, can solve the problems of insufficient research on alloying and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A superelastic Fe-Mn-Al-Ni-Nb shape memory alloy, the alloy elements and their atomic percentages are:

[0034] Mn: 20.00%; Al: 16.00%; Ni: 14.0%; Nb: 0.50%;

[0035] Its preparation method is as follows:

[0036] (1) According to the stoichiometry of the above elements, industrial pure iron, electrolytic aluminum, electrolytic nickel and ferroniobium are directly smelted in an induction furnace at a temperature of 1500°C and refined for 10 minutes;

[0037] (2) After the alloy in step (1) is completely melted and maintained for 3 minutes, ferromanganese is added, the alloy melt is mixed uniformly and then kept at 1500° C. for 10 minutes, and then cooled to room temperature with the furnace to obtain an ingot;

[0038] (3) heating the ingot in step (2) to 1100° C. for homogenization treatment for 12 hours in a vacuum furnace, and then cooling to room temperature with the furnace to obtain the treated ingot;

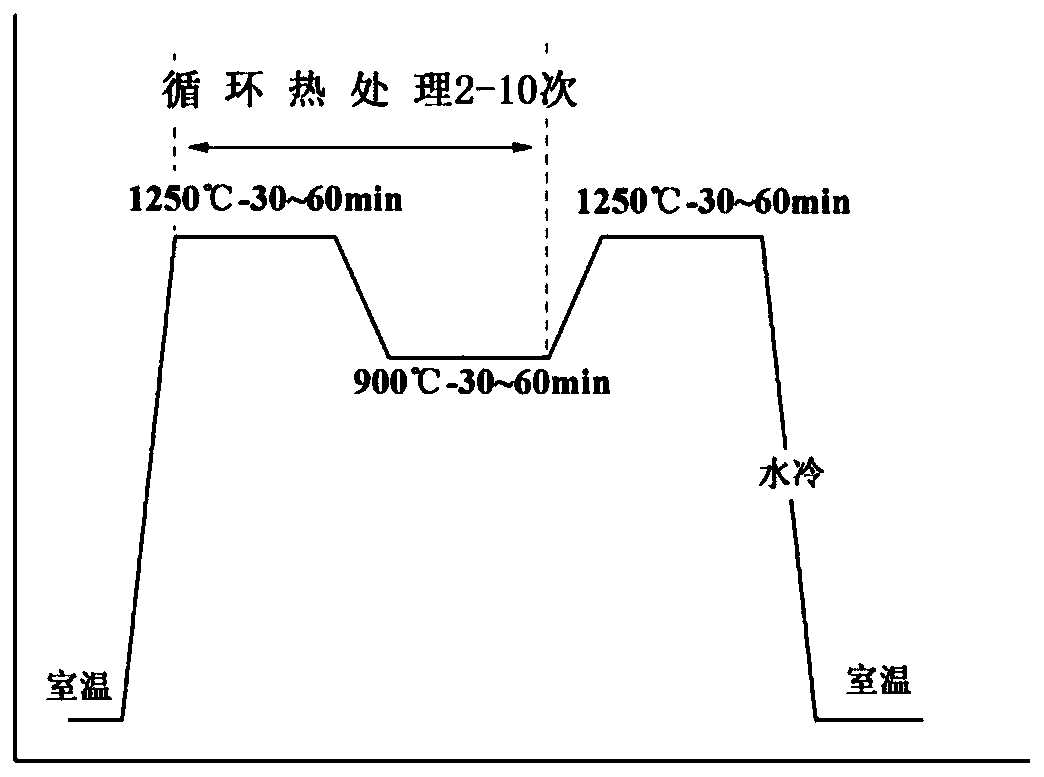

[0039] (4) Cut strip samples of appropriate size from the i...

Embodiment 2

[0046] A superelastic Fe-Mn-Al-Ni-Nb shape memory alloy, the alloy elements and their atomic percentages are:

[0047] Mn: 28.50%; Al: 20.00%; Ni: 11.00%; Nb: 1.00%; Fe: balance.

[0048] Its preparation method is as follows:

[0049] (1) According to the stoichiometry of the above elements, industrial pure iron, electrolytic aluminum, electrolytic nickel and ferroniobium were directly smelted in an induction furnace at a temperature of 1550°C for 8 minutes of refining.

[0050] (2) After the alloy in step (1) is completely melted and maintained for 5 minutes, ferromanganese is added, the molten alloy is mixed evenly and kept at 1550° C. for 8 minutes, and then cooled to room temperature with the furnace to obtain an ingot.

[0051] (3) heating the ingot in step (2) to 1100° C. for homogenization treatment for 10 hours in a vacuum furnace, and then cooling to room temperature with the furnace to obtain the treated ingot;

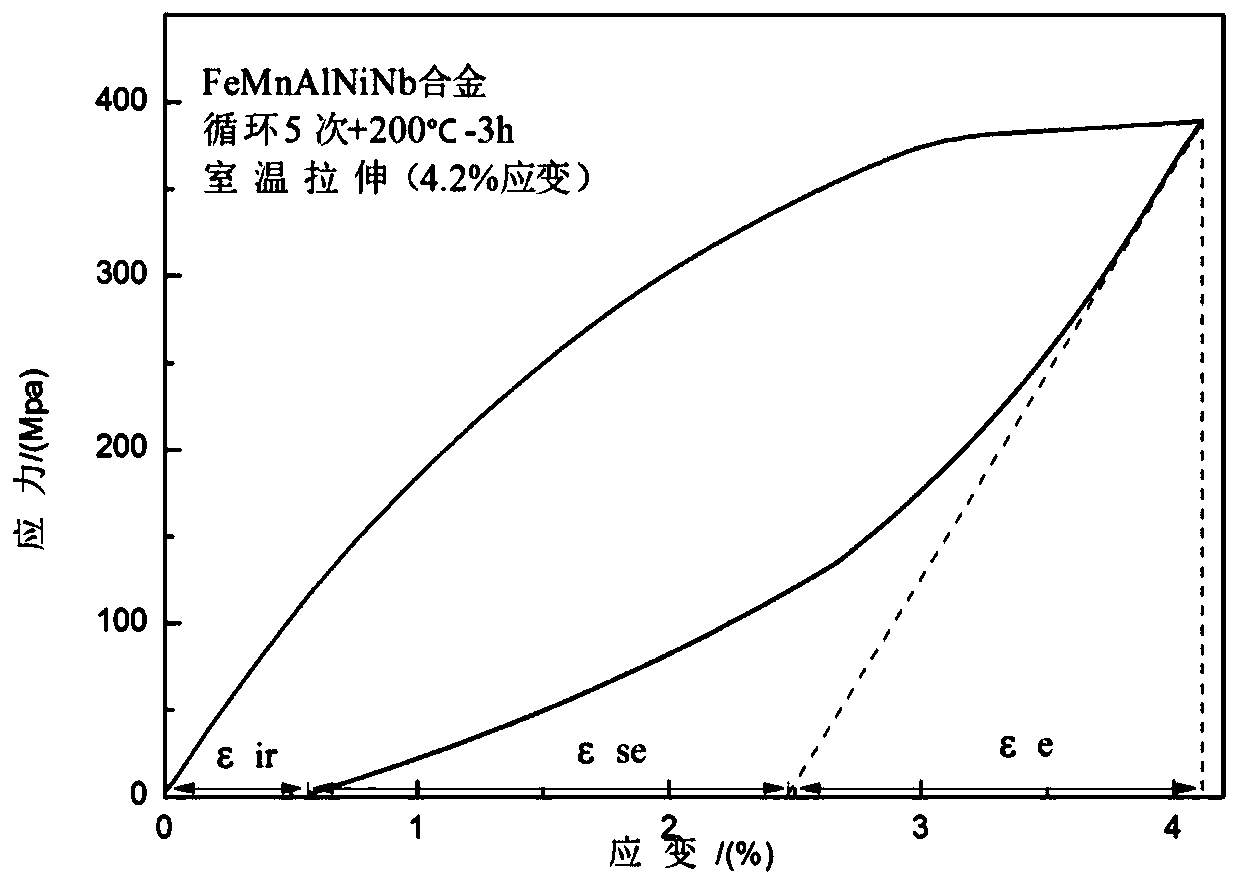

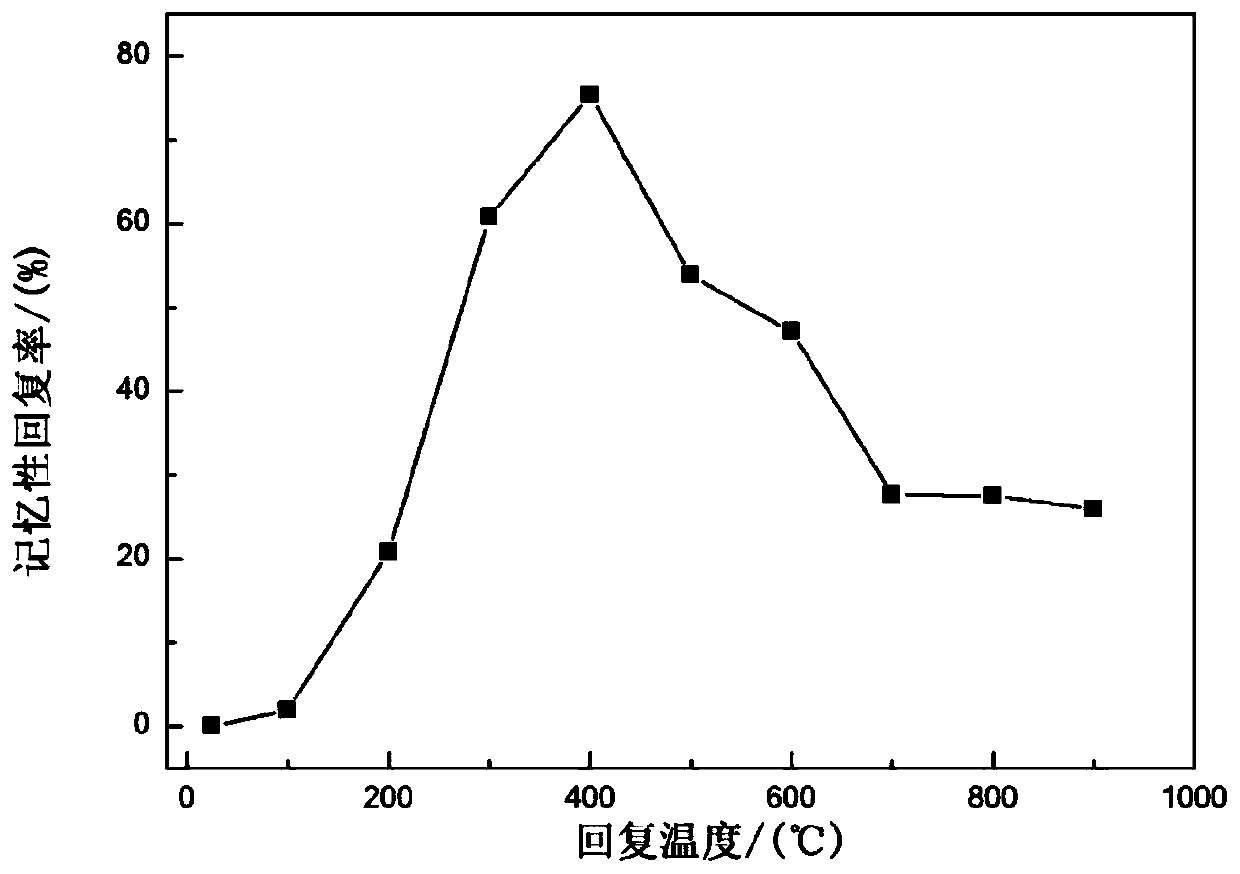

[0052] (4) Cut strip samples of appropriate size fro...

Embodiment 3

[0059] A superelastic Fe-Mn-Al-Ni-Nb shape memory alloy, the alloy elements and their atomic percentages are:

[0060] Mn: 36.50%; Al: 15.50%; Ni: 7.50%; Nb: 1.00%; Fe: balance.

[0061] Its preparation method is as follows:

[0062] (1) According to the stoichiometry of the above elements, industrial pure iron, electrolytic aluminum, electrolytic nickel and ferroniobium are directly smelted in an induction furnace at a temperature of 1550°C for 10 minutes of refining;

[0063] (2) After the alloy in step (1) is completely melted and maintained for 5 minutes, ferromanganese is added, the alloy melt is mixed uniformly and then kept at 1550° C. for 10 minutes, and then cooled to room temperature with the furnace to obtain an ingot;

[0064] (3) heating the ingot in step (2) to 1100° C. for homogenization treatment for 10 hours in a vacuum furnace, and then cooling to room temperature with the furnace to obtain the treated ingot;

[0065] (4) Cut strip samples of appropriate si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com