Preparation method of magnetic wave-absorbing resin

A magnetic wave-absorbing and resin-based technology, which is applied to the magnetism of organic materials/organic magnetic materials, magnetic field/electric field shielding, and electrical components, can solve problems such as narrow wave-absorbing frequency band, weak absorption strength, and poor low-frequency performance. Simple and feasible, low production cost, mature and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

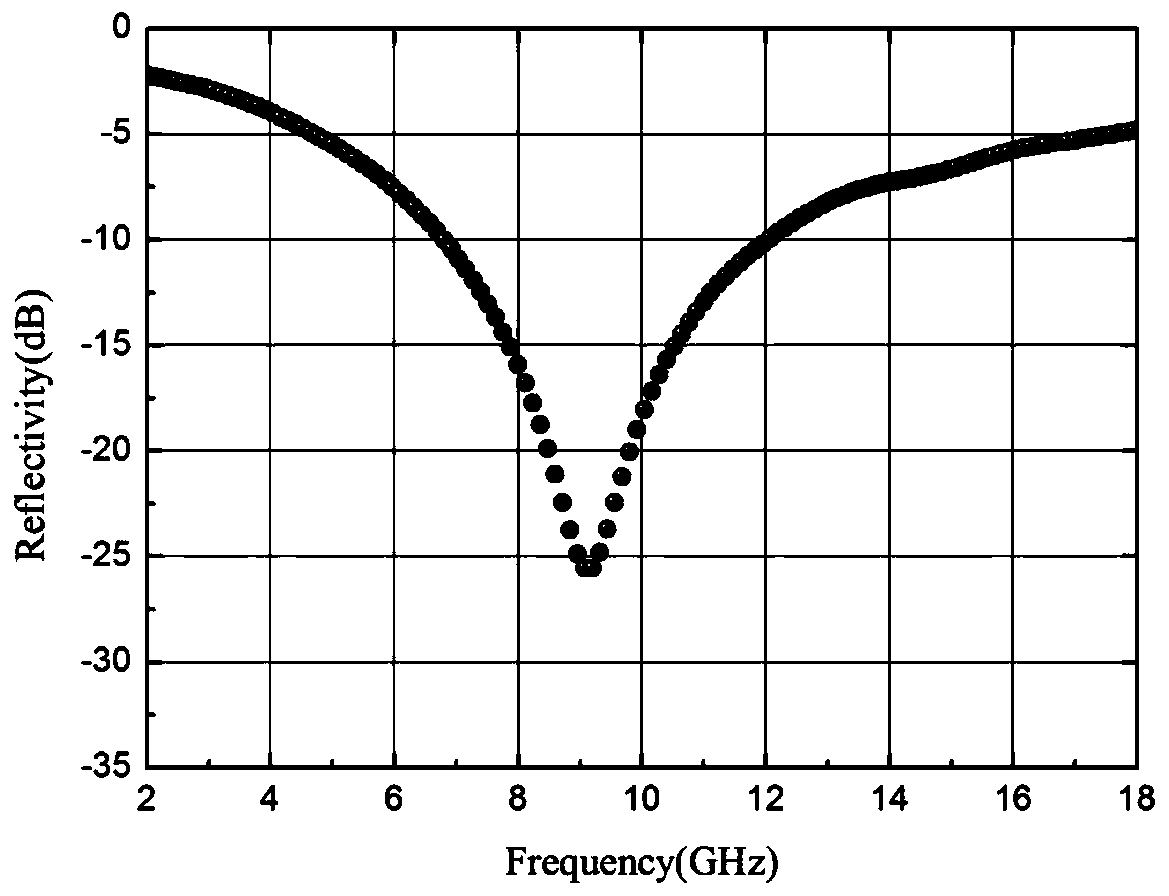

[0033] The invention provides a preparation method of magnetic wave-absorbing resin. The method provided by the present invention uses magnetic absorbent and graphene to modify the resin matrix, and the composite modified material composed of magnetic absorbent and graphene will form a conductive network inside the resin matrix, which enhances the electromagnetic loss of the wave-absorbing material , while reducing the density of the absorbing material, it improves its absorbing performance and broadens the absorbing bandwidth. In addition, the method provided by the invention is simple and feasible, the process is mature and stable, the production cost is low, and large-scale production is possible.

[0034] Specifically, the preparation method provided by the present invention includes the following steps: mixing and ball milling the magnetic absorber and graphene according to a mass ratio of (20-200):1 to obtain a composite modified material, and then combining the composit...

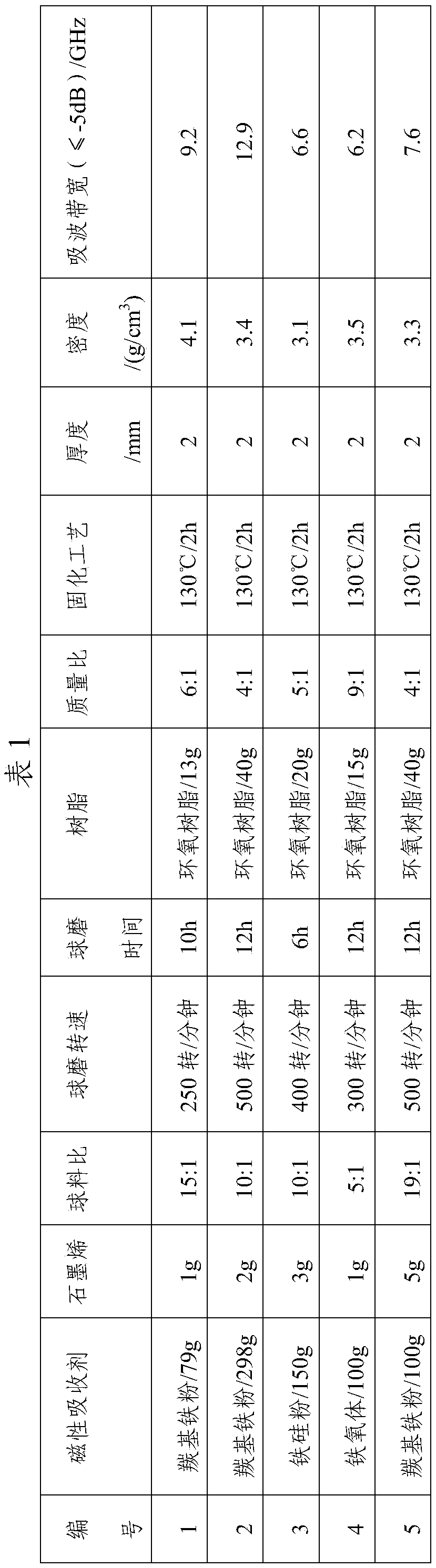

Embodiment 1

[0061] (1) Add 79g of carbonyl iron powder and 1g of single-layer graphene into the ball mill jar, then add 1200g of stainless steel balls and 160g of absolute ethanol, seal the ball mill jar and put it into a planetary ball mill with the speed set at 250 rpm / min, ball milling for 10 hours. After the ball mill tank is cooled, the obtained product is separated from the balls by sieving, put into a vacuum drying oven, and dried at 60° C. for 8 hours in a vacuum state to obtain a composite modified material.

[0062] (2) Put 13g of epoxy resin into a carrier cup, put it into an oven, and heat it at 70°C until the resin becomes thinner. Add 80g of the composite modified material prepared in step (1), and add 1g of curing agent. Put the carrier cup into the homogenizer, set the speed at 1500r / min, stir for 2 minutes until the mixture is uniform, and obtain a mixture of carbonyl iron powder / graphene sample and epoxy resin.

[0063] (3) Add the mixture prepared in step (2) into a ...

Embodiment 2

[0065] (1) Add 298g of carbonyl iron powder and 2g of single-layer graphene into the ball mill jar, then add 3000g of stainless steel balls and 300g of absolute ethanol, seal the ball mill jar and put it into a planetary ball mill, and set the speed at 500 rpm / min, ball milling for 12 hours. After the ball mill tank is cooled, the obtained product is separated from the balls by sieving, put into a vacuum drying oven, and dried at 60° C. for 8 hours in a vacuum state to obtain a composite modified material.

[0066] (2) Put 40g of epoxy resin into a carrier cup, put it into an oven, and heat it at 70°C until the resin becomes thinner. Add 160g of the composite modified material prepared in step (1), and add 2g of curing agent. Put the carrier cup into the homogenizer, set the speed at 1500r / min, stir for 2 minutes until the mixture is uniform, and obtain a mixture of carbonyl iron powder / graphene sample and epoxy resin.

[0067] (3) Add the mixture prepared in step (2) into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com