A method for preparing metal-organic framework materials for detecting oxidizing gases

A metal-organic framework and oxidizing gas technology, applied in the field of gas sensing, can solve the problems of visualization, inability to use independently and color change, etc., achieve good sensing performance, easy to synthesize in large quantities, and stabilize the skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for detecting a metal organic skeleton material for detecting oxidizing gases (e.g., nitrid), including the following steps:

[0030] 1) Mass moon ratio 1.5: 1-3: 1 (preferably 2: 1), 4-cyanopyridine and hydrated hydrazine and mixed into the reaction vessel, stirred at 30-80 ° C (preferably 80 ° C), stirring reflow reaction 4-8h (preferably 4h); filtration to obtain an orange-yellow solid, recrystallized in a mixed solvent of ethanol and water volume ratio of 0.5 to 1.5: 1, and washed with orange-yellow solid dihydro-3,6-2-4 - Pyridyl-1,2,4,5-tetrazine, purity is greater than 98%, spare.

[0031] 2) Dissolve dihydro-3,6 -,4-pyridyl-1,2,4,5-tetrazine in methanol at 40-50 mg / 30-40 mL, and ultrasonic shock during period.

[0032] 3) The resulting reactant was slow (0.05 to 0.2 ml / s of dripping) under stirring (0.9-1.1 mol / L), dihydro-3,6-bis -2- The molar ratio of 4-pyridyl-1,2,4,5-tetrazine and the copper of hexafluorosilicone is 1: 1-2: 1. The resulting mixed ...

Embodiment 1

[0035] Preparation of dihydro-3,6-di-4-pyridyl-1,2,4,5-tetrazine:

[0036] 5.2 g of 4-cyanohydridine and 5 ml of hydrated hydrazine were weighted, respectively, in a 100 ml round bottom flask, with a molar ratio of 4-cyanopyridine and hydrazine hydrazine of 2: 1, stirred at 80 ° C for 4 h. The orange-yellow solid was filtered with a brutal funnel, and the orange powder spare was obtained by recrystallization in a mixed solvent of ethanol and a water volume ratio of 1: 1 and washed.

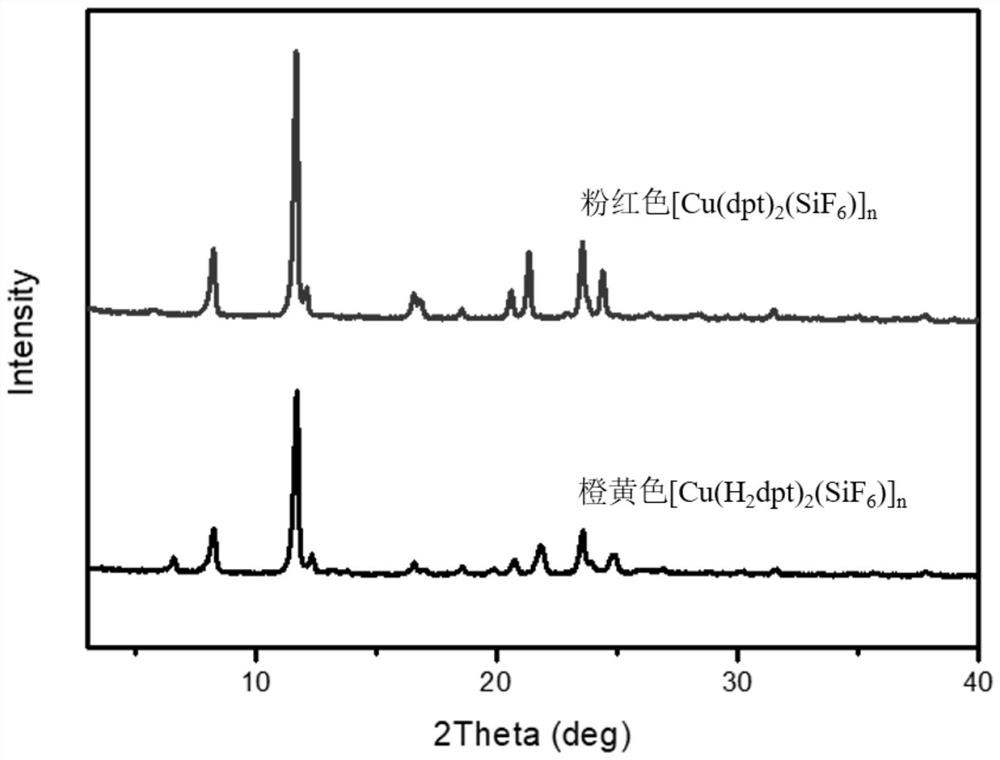

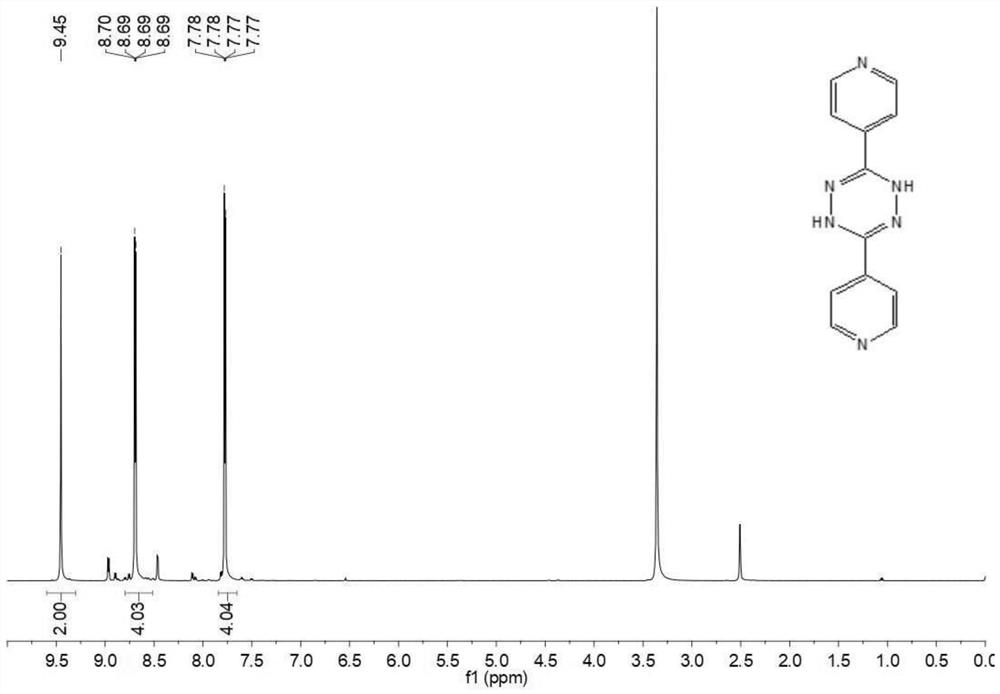

[0037] Example 1 prepared from the homemade raw material under optimal conditions, with high purity, purity up to 98% (eg figure 2 The desired nuclear magnetic spectrogram: 1 H NMR (500 MHz, DMSO) δ 9.45 (S, 2H), 8.69 (DD, J = 4.6, 1.5 Hz, 4H), 7.77 (DD, J = 4.6, 1.6 Hz, 4H), two in the subsequent embodiment Hydrogen-3,6-di-4-pyridyl-1,2,4,5-tetrazine (H 2 DPT is obtained by synthesizing this example.

[0038] Preparation and application of metal organic skeleton materials:

[0039] 46 mg of dihydro-3...

Embodiment 2

[0042] 46 mg of dihydro-3,6-di-4-pyridyl-1,2,4,5-tetrazine ligand was dissolved in 30 ml of methanol, and then the reactant was placed on the stirrer and slowly dripped during stirring.成 (0.1 ml / s) 2 ml Cusif 6 Aqueous solution (1 mol / L), dihydro-3,6-di-4-pyridyl-1,2,4,5-tetrazine and hexfluoron silicate copper with a molar ratio of 1: 1 (ligand slightly over) . After mixing, the solution was reacted at 50 ° C for 20 h, and then filtered with a bunt funnel to obtain an orange powder, and the methanol was rinsed several times to obtain a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com