Curing agent for high-solid water-based coating

A water-based, curing agent technology, applied in the field of coating materials, can solve the problems of poor weather resistance and variability, and achieve the effects of good anti-sag performance, convenient construction, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

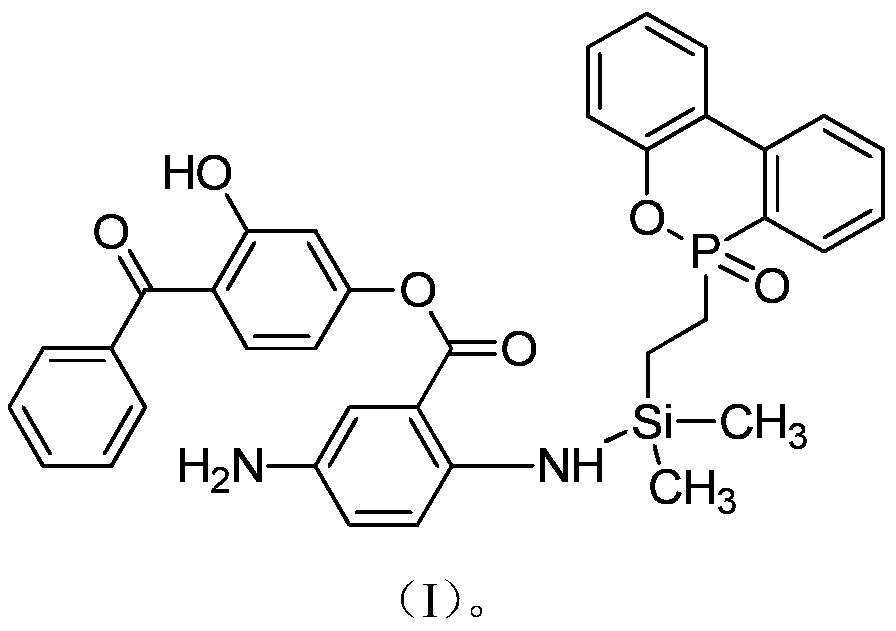

Image

Examples

Embodiment 1

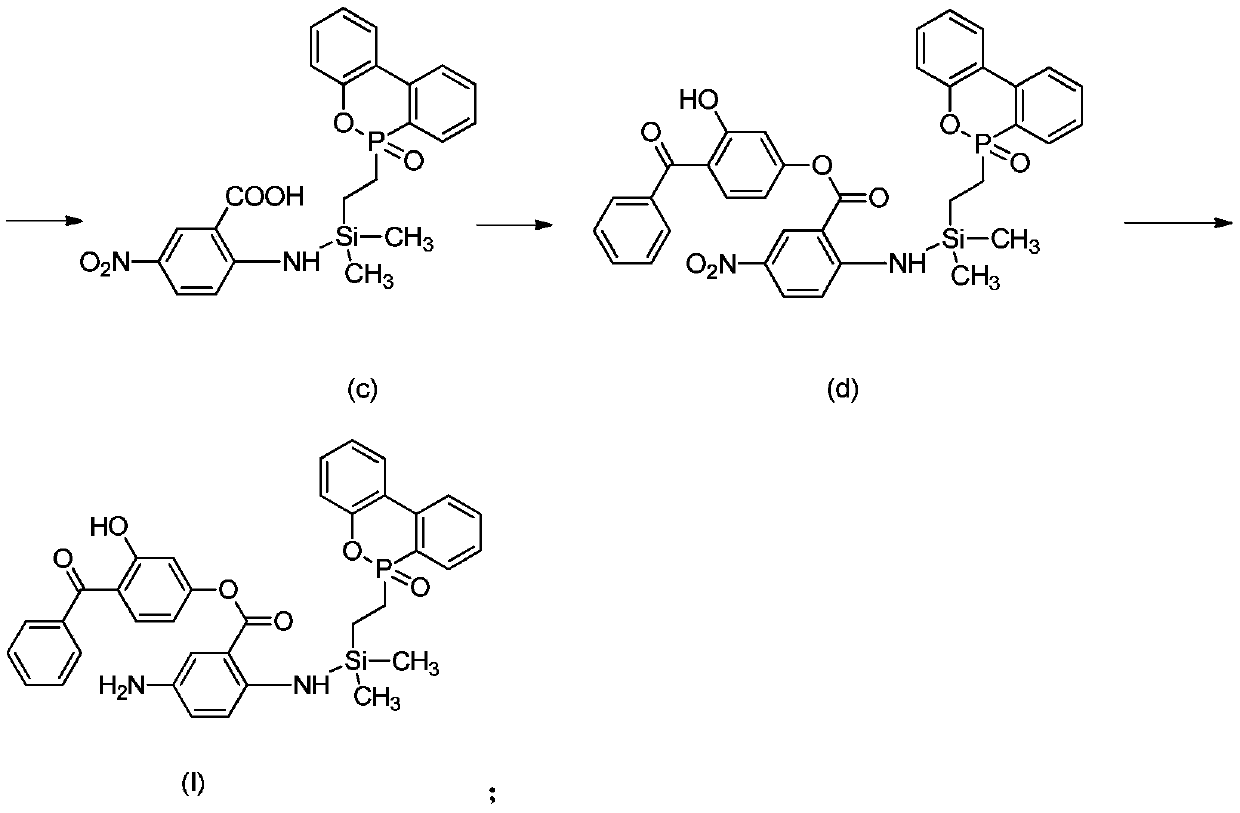

[0029] The preparation of embodiment 1 formula a compound

[0030] Weigh 11.30 g of methyl 2-amino-5-nitrobenzoate into a reaction flask, add 60 mL of tetrahydrofuran and 30 mL of triethylamine to dissolve, then add 10 mL of tetrahydrofuran in which 12.05 g of vinyl dimethyl chlorosilane is dissolved dropwise at room temperature Solution, dropwise, stirred overnight at 45°C, after the reaction, cooled to room temperature, added 80 mL of water, extracted with dichloromethane (3*50 mL), combined the dichloromethane layers, dried over anhydrous sodium sulfate, filtered, evaporated the solvent under reduced pressure That is, it was directly used in the next step without purification.

[0031] ES: M / Z 281[M+H] + .

Embodiment 2

[0032] Embodiment 2: the preparation of formula b compound

[0033] Weigh 5g of DOPO into the reaction flask, add 7.2g of the compound of formula a obtained in Example 1, 80ml of dioxane, and reflux for 10h under nitrogen protection. After the reaction, cool to room temperature, evaporate the solvent under reduced pressure, and perform column chromatography The compound of formula b is obtained by purification.

[0034] ES: M / Z 497[M+H] + .

[0035] 1 H NMR (600MHz, CDCl 3 )(δ,ppm):8.36~8.34(m,1H),8.24~8.22(m,1H),7.98~7.96(m,1H),7.80~7.79(m,1H),7.67~7.65(m,1H ),7.55~7.53(m,1H),7.42~7.40(m,1H),7.25~7.24(m,1H),7.09~7.07(m,1H),7.01~7.00(m,2H),4.05(s ,1H), 3.90(s,3H), 1.85~1.83(m,2H), 1.05~1.04(m,2H), 0.09(s,6H).

Embodiment 3

[0036] Embodiment 3: the preparation of formula c compound

[0037] Weigh 4.2g of the compound of formula b obtained in Example 2 into a reaction flask, add 20mL of 40% aqueous sodium hydroxide solution, stir at 70°C for 2h, after the reaction is completed, cool to room temperature, adjust the pH to about 7 with 1M hydrochloric acid, Dichloromethane was added for extraction (3*20 mL), several layers were combined, dried over anhydrous sodium sulfate, filtered, the solvent was evaporated under reduced pressure, and the residue was recrystallized from methanol to obtain the compound of formula c.

[0038] ES: M / Z 483[M+H] + .

[0039] 1 H NMR (600MHz, CDCl 3 )(δ,ppm):11.88(br,1H),8.59~8.57(m,1H),8.38~8.37(m,1H),7.97~7.96(m,1H),7.83~7.81(m,1H), 7.66~7.65(m,1H),7.55~7.53(m,1H),7.42~7.40(m,1H),7.25~7.24(m,1H),7.09~7.07(m,1H),7.01~7.00(m ,2H), 4.05(s,1H), 1.88~1.86(m,2H), 1.10~1.09(m,2H), 0.09(s,6H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com