Waterproof antibacterial directional shaving board and preparation method thereof

A technology of oriented strand board and shavings, which is applied to chemical instruments and methods, flat products, manufacturing tools, etc. It can solve the problems of mildew, easy cracking and delamination of the board body, and achieve uniform internal stress distribution, good physical and mechanical properties, and surface Good finishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

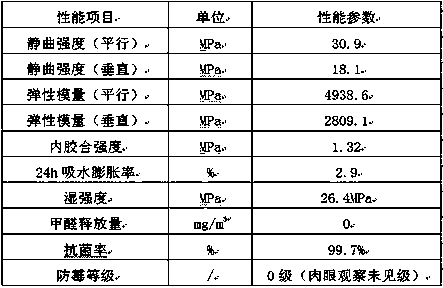

Embodiment 1

[0043] A waterproof and antibacterial oriented strand board, comprising an upper surface layer, a core layer and a lower surface layer;

[0044] The mass ratio of the upper and lower surface layers to the core layer is 60%:40%;

[0045] The mass ratio of the upper surface layer to the lower surface layer is 1:1;

[0046] The pavement angle between the upper and lower surface layers and the core layer is 80°;

[0047] The upper surface layer, the core layer and the lower surface layer are composed of shavings, and the size of the shavings is 80mm in length, 15mm in width and 0.3mm in thickness.

[0048] A method for preparing waterproof and antibacterial oriented strand board, comprising shaving, drying, mixing and spraying, drying, sizing, paving, liquid spraying and hot pressing, slab balancing, trimming, cooling, sanding and film formation.

[0049] For the shavings, the shavings of a predetermined specification are obtained after the large-diameter logs are cut into shavi...

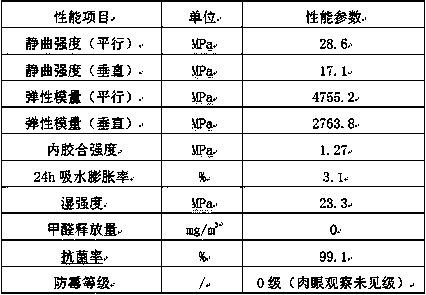

Embodiment 2

[0069] A waterproof and antibacterial oriented strand board, comprising an upper surface layer, a core layer and a lower surface layer;

[0070] The mass ratio of the upper and lower surface layers to the core layer is 65%: 35%;

[0071] The mass ratio of the upper surface layer to the lower surface layer is 1:1;

[0072] The angle between the upper and lower surface layers and the core layer paving is 90°;

[0073] The upper surface layer, the core layer and the lower surface layer are composed of shavings, and the size of the shavings is 140mm in length, 30mm in width and 0.7mm in thickness.

[0074] A method for preparing waterproof and antibacterial oriented strand board, comprising shaving, drying, mixing and spraying, drying, sizing, paving, liquid spraying and hot pressing, slab balancing, trimming, cooling, sanding and film formation.

[0075] For the shavings, the shavings of a predetermined specification are obtained after the large-diameter logs are cut into shavi...

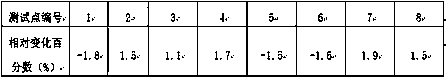

Embodiment 3

[0095] A waterproof and antibacterial oriented strand board, comprising an upper surface layer, a core layer and a lower surface layer;

[0096] The mass ratio of the upper and lower surface layers to the core layer is 75%: 25%;

[0097] The mass ratio of the upper surface layer to the lower surface layer is 1:1;

[0098] The angle between the upper and lower surface layers and the core layer paving is 85°;

[0099] The upper surface layer, the core layer and the lower surface layer are composed of shavings, and the size of the shavings is 120mm in length, 20mm in width and 0.5mm in thickness.

[0100]A method for preparing waterproof and antibacterial oriented strand board, comprising shaving, drying, mixing and spraying, drying, sizing, paving, liquid spraying and hot pressing, slab balancing, trimming, cooling, sanding and film formation.

[0101] As for the shavings, the shavings of predetermined specifications are obtained after the large-diameter logs are cut and shavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com