Insulation coating device and coating process for high-efficiency metal magnetic powder

A metal magnetic powder and insulation coating technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of long time-consuming insulation coating process, no coating device, high production cost, etc., to shorten the insulation coating time, The effect of huge application market and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

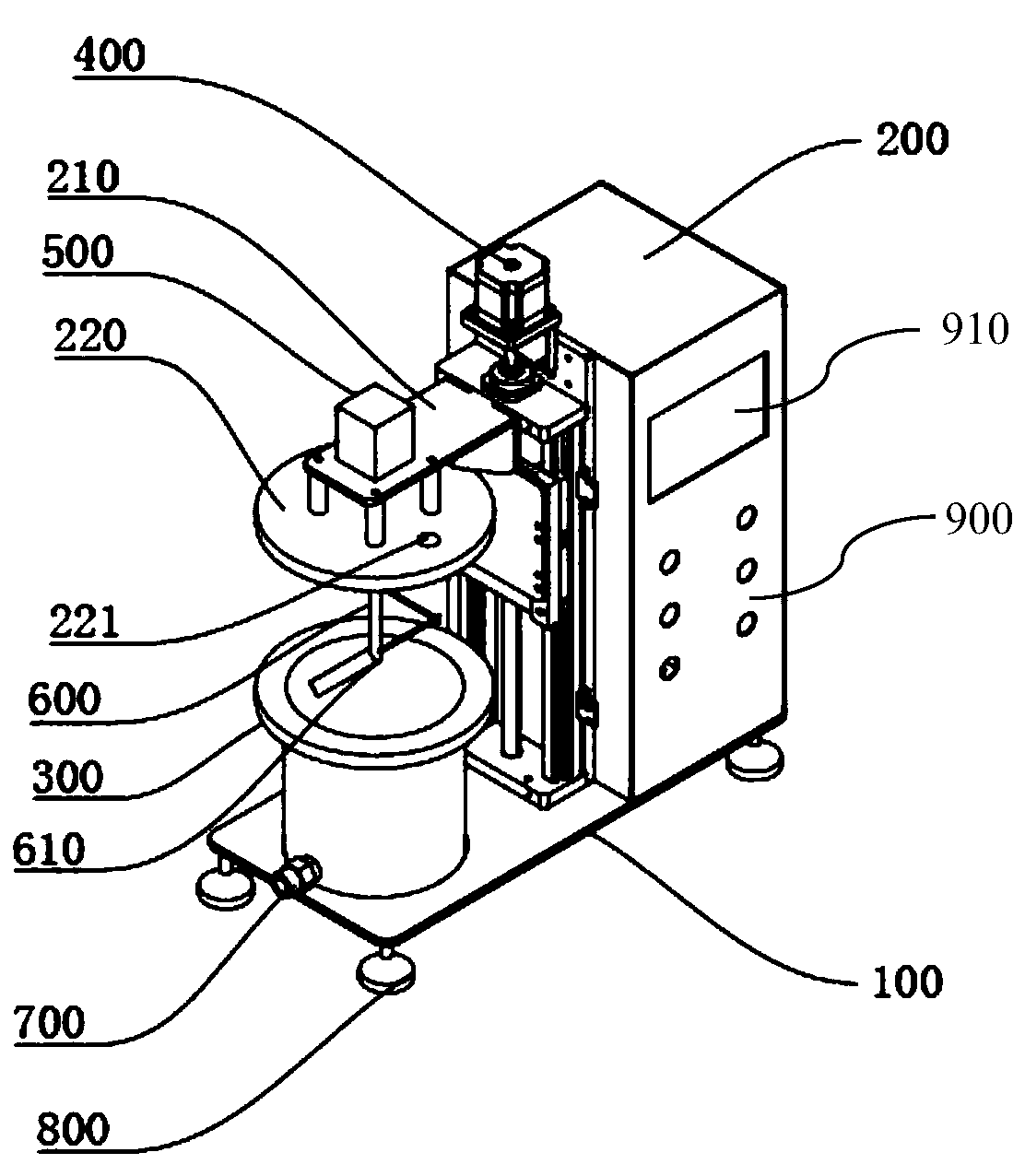

[0032] The main dimensions of the metal magnetic powder insulation coating device used for the small test in the laboratory are as follows: the inner diameter of the stirring container 300 is 160mm, and the height is 200mm; the power of the motor 500 is 500W; the maximum diameter of the stirring paddle 610 is 150mm, which The total number of layers on the 600 is 2 layers, the layer spacing is 60mm, and the angle between the left blade and the right blade is 90°; the thickness of the round cake-shaped organic transparent resin cover is 80mm, the diameter is 300mm, and the distance between A feeding port 221 with a diameter of 25 mm is provided at a center distance of 75 mm. The inner and outer diameters of the annular plastic sealing ring are 240 mm and 300 mm respectively, and the thickness is 50 mm; the distance between the bottom of the drainage channel 700 and the bottom of the stirring container 300 is 12mm, the filter screen is composed of two overlapping layers of -200 me...

Embodiment 2

[0035] The main dimensions of the metal magnetic powder insulation coating device during the pilot test are as follows: the inner diameter of the stirring container 300 is 600mm, and the height is 900mm; the power of the motor 500 is 2500W; the maximum diameter of the stirring paddle 610 is 585mm, and its The total number of layers is 3 layers, and the layer spacing is 130mm, and the angle between the left paddle and the right paddle on the stirring shaft 600 is 90°; Its center distance is 180mm place and is provided with the feeding port 221 that diameter is 45mm, and the inner and outer diameters of annular plastic sealing ring are respectively 780mm and 850mm, and thickness is 60mm; The filter screen is 16mm, and the filter screen is composed of three overlapping layers of -200 mesh screens with a diameter of 80mm. The material of the screen gasket is rubber, and the shape is a ring. The size is consistent with that of the filter screen. The material of the drainage channel...

Embodiment 3

[0038] The main dimensions of the metal magnetic powder insulation coating device used in the pilot test are as follows: the inner diameter of the stirring container 300 is 2700mm, and the height is 3900mm; the power of the motor 500 is 7000W; the maximum diameter of the stirring paddle 610 is 2680mm, and its The total number of layers is 5 layers, the layer spacing is 320mm, and the angle between the left paddle and the right paddle on the stirring shaft 600 is 90°; the thickness of the round cake-shaped organic transparent resin cover is 150mm, and the diameter is 2920mm. A feed port 221 with a diameter of 65 mm is provided at a distance of 805 mm from its center. The inner and outer diameters of the ring-shaped plastic sealing ring are 2700 mm and 2920 mm respectively, and the thickness is 70 mm; The filter screen is composed of three overlapping layers of -200 mesh screens with a diameter of 150mm. The material of the screen seal gasket is rubber and the shape is ring-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com