Preparation method capable of improving quality of air-dried sausages based on biofilm

A biofilm, air-dried sausage technology, applied in the direction of preservation of bacteria and food ingredients used in food preparation as antimicrobials, food ingredients containing natural extracts, etc., to ensure product safety, improve gelation, and prevent oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

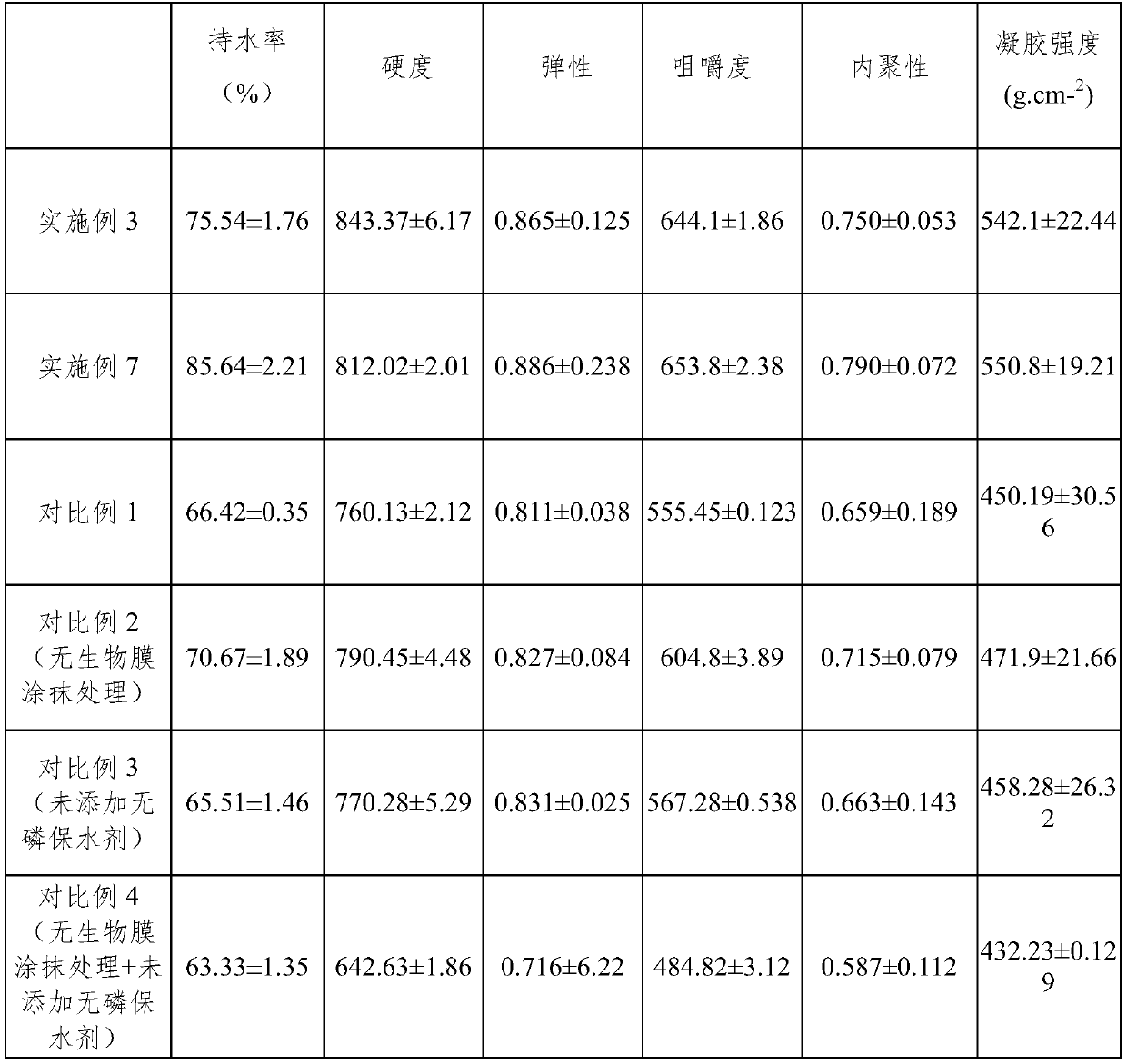

Examples

Embodiment 1

[0033] The preparation method of high-quality air-dried sausage, it comprises the following steps:

[0034] S1 preprocessing:

[0035] S11 Cleaning: Wash the fresh pork hind legs successively with water, deboning, peeling, removing connective tissue, and washing with clean water;

[0036] S12 Grinding: Put the pork hind legs processed in S11 into a chopping machine, chop and mix well and evenly for 6 minutes, add ice cubes during the chopping to keep the meat temperature below 5°C;

[0037] S13 Marinating: Add salt preparation to the chopped pork hind legs, stir evenly, and marinate at 4°C for 4 hours. The addition amount of salt preparation is 5%, and salt preparation is (salt: Chinese prickly ash=10:1).

[0038] S3 Mixing: Add auxiliary materials to the marinated pig hind legs, mix well and evenly chop and mix for 5-8 minutes to obtain meat materials; the weight percentages of each component in the auxiliary materials accounted for pig hind legs are: salt 6% , monosodium ...

Embodiment 2

[0046] The preparation method of high-quality air-dried sausage, it comprises the following steps:

[0047] S1 preprocessing:

[0048] S11 Cleaning: Wash the fresh pork hind legs successively with water, deboning, peeling, removing connective tissue, and washing with clean water;

[0049] S12 Grinding: Put the pork hind legs processed in S11 into a chopping machine, chop and mix well and evenly for 8 minutes, add ice cubes during the chopping to keep the meat temperature below 5°C;

[0050] S13 Marinating: Add salt preparation to the chopped pork hind legs, stir evenly, and marinate at 4°C for 5 hours. The addition amount of the salt preparation is 6%, and the salt preparation is (salt:Zanthoxylum bungeanum=10:1).

[0051] S3 Mixing material: add auxiliary materials to the marinated pig hind legs, mix well and evenly chop and mix for 8 minutes to obtain meat materials; the weight percentages of each component in the auxiliary materials accounted for pig hind legs are: salt 8...

Embodiment 3

[0059] The preparation method of high-quality air-dried sausage, it comprises the following steps:

[0060] S1 preprocessing:

[0061] S11 Cleaning: Wash the fresh pork hind legs successively with water, deboning, peeling, removing connective tissue, and washing with clean water;

[0062] S12 Grinding: Put the pork hind legs processed in S11 into a chopping machine, chop and mix well and evenly for 8 minutes, add ice cubes during the chopping to keep the meat temperature below 5°C;

[0063] S13 Marinating: Add salt preparation to the chopped pork hind legs, stir evenly, and marinate at 4°C for 4.5 hours. The addition amount of salt preparation is 5%, and salt preparation is (salt: Chinese prickly ash=10:1).

[0064] S3 Mixing material: Add auxiliary materials to the marinated pork hind legs, mix well and evenly chop and mix for 8 minutes to obtain meat materials; the weight percentages of each component in the auxiliary materials accounted for pig hind legs are: salt 7%, mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com