Makeup-removing cleaning towel capable of removing makeup by using clear water and production process of the makeup-removing cleaning towel

A production process and technology of cleaning towel, applied in the field of daily necessities, can solve problems such as poor effect, and achieve the effect of improving makeup removal and cleaning effect, strong water absorption, and easy makeup removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: A production process of a makeup-removing cleansing towel that can be removed with clean water, as shown in the figure, comprising the following steps:

[0033] S1, will contain nano-scale cotton fiber and nano-scale bamboo fiber to carry out proportioning, the weight ratio of nano-scale cotton fiber and bamboo fiber is 1:1, then carry out blending, weave into the warp yarn and the weft yarn of nano superfiber respectively, The ratio of nano-scale cotton fiber to bamboo fiber can make the yarn have antibacterial and deodorizing effects, and nano-scale cotton fiber has a better effect on makeup removal, which can facilitate makeup removal and cleaning;

[0034] S2, utilize low-concentration hydrogen peroxide plus composite detergent to process the yarn, wherein the dosage ratio of hydrogen peroxide and composite detergent is 2:3, to ensure the efficacy of warp and weft yarns, and facilitate the weaving of the next step;

[0035] S3. Setting various process ...

Embodiment 2

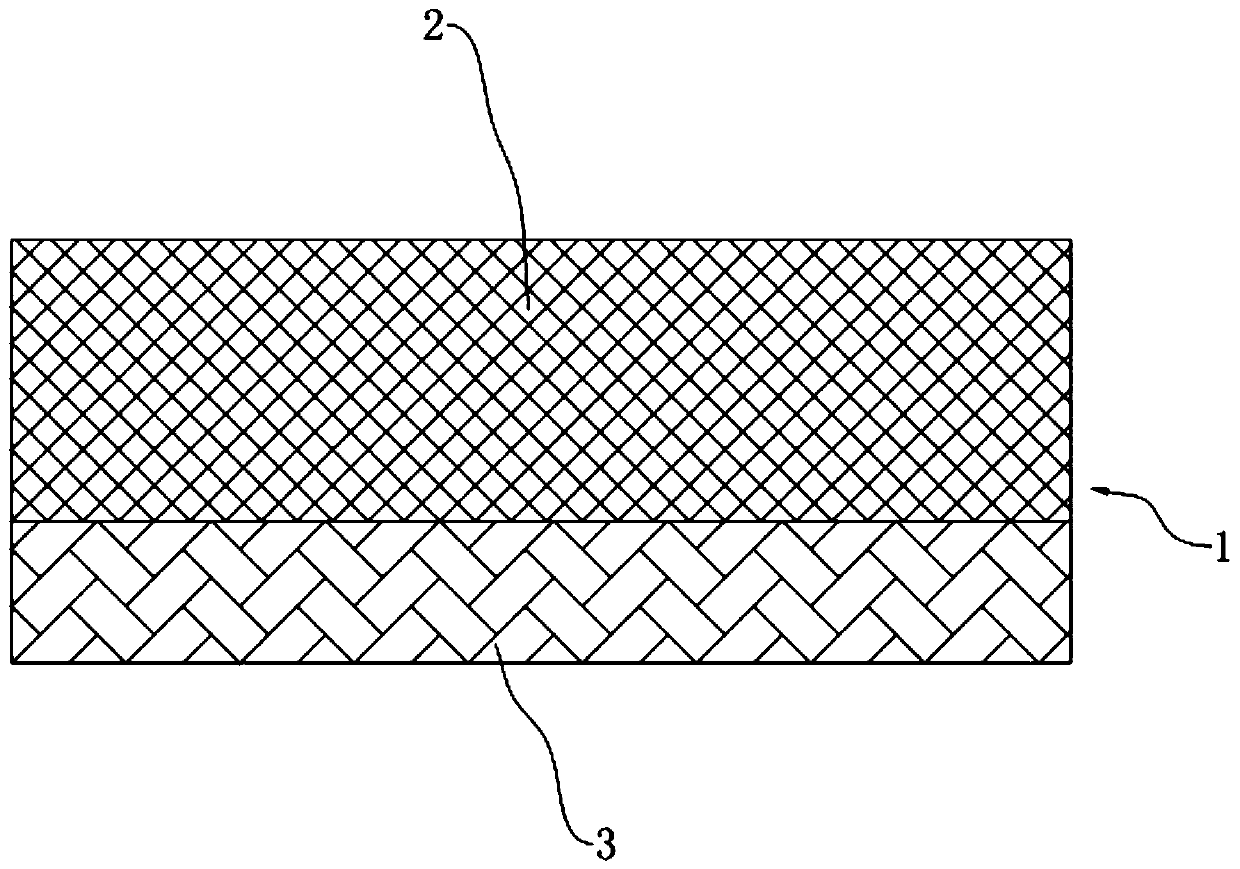

[0042] Embodiment 2: This embodiment provides a makeup remover cleaning towel that can be removed with clean water, which is made by the production process of Embodiment 1, such as figure 1 As shown, the makeup remover towel body is included, and the thickness of the gauze surface 2 of the makeup remover clean towel body 1 is greater than the thickness of the loop surface 3. Specifically, the thickness of the gauze surface 2 is twice the thickness of the loop surface 3, so that the makeup remover When in use, the gauze surface 2 and the loop surface 3 can be quickly distinguished, so that the thicker gauze surface 2 can be used for makeup removal, more stains can be cleaned and absorbed, and the makeup removal is more effective, which has the advantage of improving the cleansing effect of makeup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com