Streptomyces albulus (GS-114) and method of the same to prepare epsilon-polylysine

A technology of Streptomyces parvus and microbial strains, applied in the field of Streptomyces and its preparation of ε-polylysine, can solve the problems of not being suitable for large-scale application in breeding work, general screening effect, and high price, and achieve The effect of excellent passage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: the breeding of Streptomyces parvus GS-114

[0050] Bethner solid medium (g / 100mL): glucose 2, yeast extract 0.2, peptone 0.4, agar 2, pH 7.5, sterilized at 115°C for 20 minutes.

[0051] Antibiotic resistance medium (g / 100mL): glucose 2, yeast extract 0.2, peptone 0.4, agar 2, pH 7.5, sterilized at 115°C for 20 minutes. When the temperature of the culture medium dropped to 60°C, the stock solutions of streptomycin, gentamicin and rifamycin prepared in advance and sterilized by filtration through a 0.22 μm membrane were added thereto.

[0052] Specific steps are as follows:

[0053] (1) Construction of mutation library: 2% (v / v) DES was used to test the spores of Streptomyces albicans M-Z18 (the deposit number is CCTCC NO: M 2019589, and the strain is recorded in the patent application with application number 201911020454.4) The suspension was treated for 30min (28°C water bath), and NaS was added 2 o 3 Terminate the reaction, dilute and smear on a Bet...

Embodiment 2

[0055] Example 2: Morphological characteristics of the starting bacterium M-Z18 and the high-yield bacterium GS-114

[0056] The morphology of the strains was observed with naked eyes and microscopic analysis.

[0057] Depend on figure 1 It can be seen that there are obvious differences in morphology between the two strains. On the peptone yeast extract medium, the colony of the starting strain M-Z18 was larger, the aerial hyphae grew well, and the colony and its back were yellow or tan. In YP liquid medium, the mycelium of M-Z18 intertwined to form larger solid balls.

[0058] The colony of strain GS-114 is small. On the peptone yeast extract medium, the aerial hyphae grow well, and the spores form gray-green chains, which are oval under the microscope; the colonies and their backs are yellow-green or yellow-brown. In the YP liquid medium, the hyphae of GS-114 were loose and the balls were small.

Embodiment 3

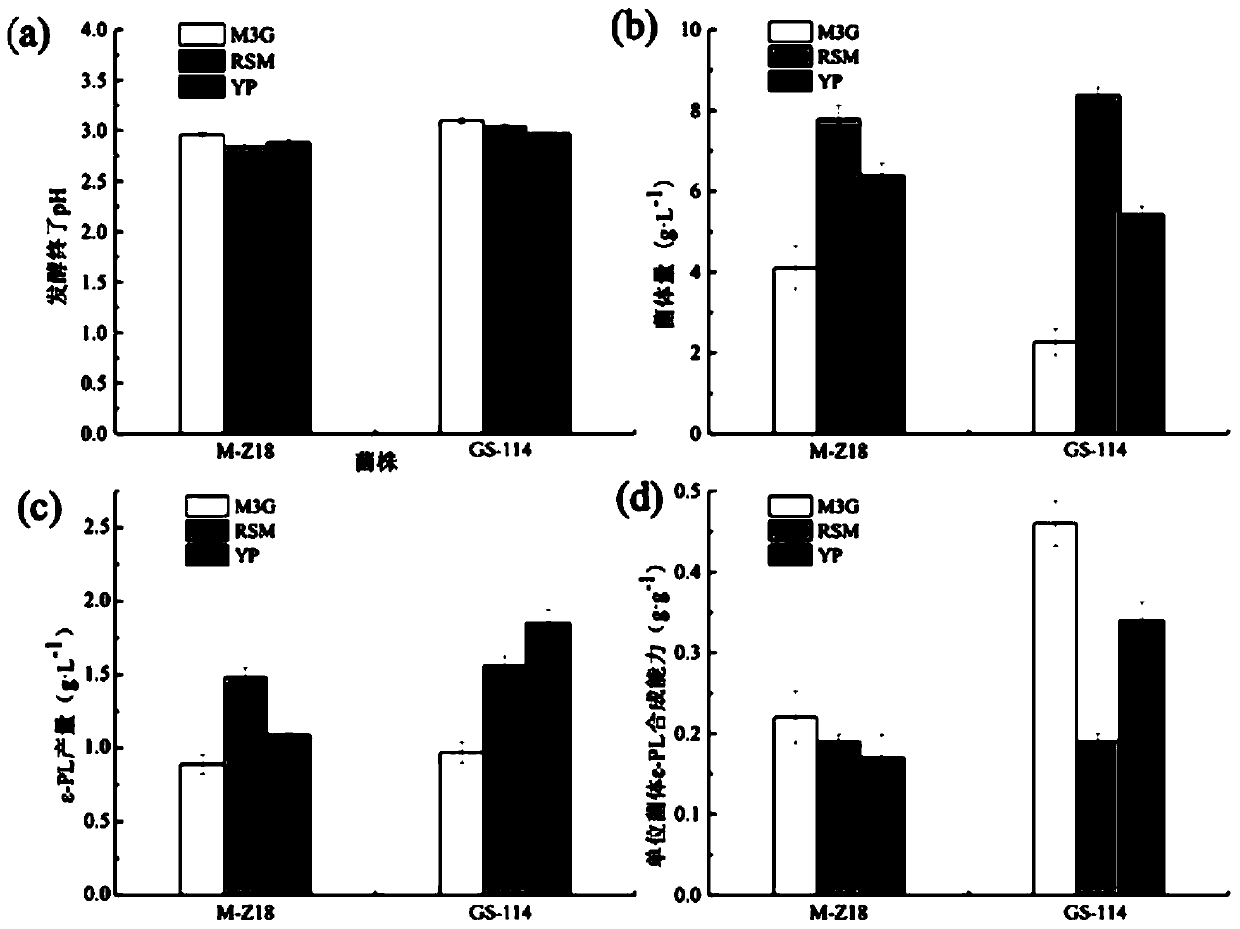

[0059] Example 3: The difference in the shake flask output of high-yielding bacteria GS-114 and starting bacteria M-Z18 under different medium conditions

[0060] M3G seed medium (by g / 100mL): glucose 5, (NH 4 ) 2 SO 4 1, Na 2 HPO 4 0.14, KH 2 PO 4 0.1, MgSO 7 ·H 2 O 0.025, ZnSO 7 ·H 2 O 0.005, FeSO 7 ·H 2 O 0.001, yeast powder 0.5, pH 6.8, sterilized at 115°C for 20min.

[0061] RSM liquid fermentation medium (by g / 100mL): glucose 6, (NH 4 ) 2 SO 4 0.5, beef extract 1, KH 2 PO 4 0.4, MgSO 4 0.08, FeSO 4 0.005, sterilized at 115°C for 20 minutes, fermented at natural pH.

[0062] YP liquid fermentation medium (by g / 100mL): glucose 3, (NH 4 ) 2 SO 4 0.5, yeast powder 0.8, KH 2 PO 4 0.4, MgSO 4 0.08, FeSO 4 0.005, sterilized at 115°C for 20 minutes, fermented at natural pH.

[0063] The purified GS-114 spores were inoculated into the medium filled with M3G, and cultured in shake flasks at 30°C×200rpm for 24h to prepare seed liquid. The seed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com