Preparation method of high-temperature-resistant coating with self-cleaning performance

A high-temperature-resistant coating and self-cleaning technology, which is applied in the direction of fireproof coatings and coatings, can solve the problems of high price of inorganic pigments, complicated preparation process, and high price, and achieve strong operability of the preparation process, simple preparation method, and high production efficiency. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

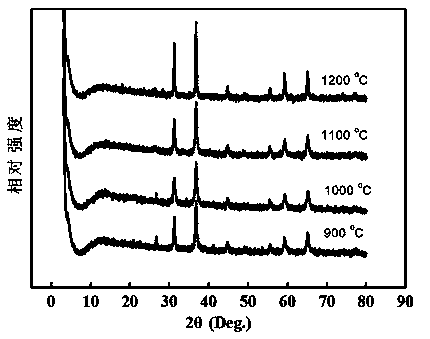

[0033] ①Preparation of cobalt blue hybrid pigment: Accurately weigh 109 g of kaolinite, 81 g of dicobalt oxide, and 102 g of aluminum oxide and mix them evenly. A blue cobalt blue hybrid pigment is obtained, and the sample number is S0.

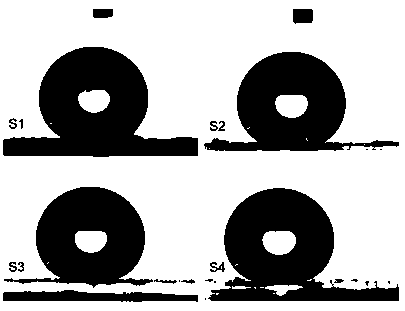

[0034] ②Preparation of superhydrophobic hybrid pigments: Disperse 5 g of the prepared cobalt blue kaolinite hybrid pigments in 50 mL of ethanol, add 0.5 g monoethanolamine solution, 0.5 g water, 0.5 g dodecyltriethoxy Silane and stirred evenly, after reacting for 8 hours, the superhydrophobic modified cobalt blue kaolinite hybrid pigment was prepared;

[0035] ③Preparation of superhydrophobic heat-resistant coating: In a certain container, add 60g of silicone resin 9801, 10g of modified cobalt blue hybrid pigment, 10g of ceramic powder, 14g of glass fiber and other pigments and fillers, stir for a certain period of time, then add 5g Leveling agent (BYK333), 1g defoamer (BYK024), adjust viscosity, place for aging, spray board, prepare heat-re...

Embodiment 2

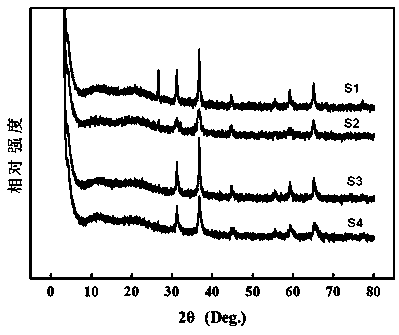

[0037] ①Preparation of cobalt blue hybrid pigment: Accurately weigh 40.5 g of halloysite, 81 g of dicobalt trioxide, and 204 g of aluminum oxide and mix them evenly. A blue cobalt blue hybrid pigment is obtained, and the sample number is S1.

[0038] ②Preparation of superhydrophobic hybrid pigment: Disperse 5 g of cobalt blue halloysite hybrid pigment in 10 mL of ethanol, add 2.5 g of diethanolamine solution, 2.5 g of water, 2.5 g of dodecyltriethoxy Silane and stirred evenly, after reacting for 12 hours, a superhydrophobic modified cobalt blue halloysite hybrid pigment was prepared;

[0039] ③Preparation of superhydrophobic heat-resistant coating: In a certain container, add 40g of silicone resin 9801, 15g of modified cobalt blue hybrid pigment, 15g of ceramic powder, 25g of glass fiber and other pigments and fillers, stir for a certain period of time, then add 4 g Leveling agent (BYK333), 1g defoamer (BYK024), adjust viscosity, place for aging, spray board, prepare heat-res...

Embodiment 3

[0041] ①Preparation of cobalt blue hybrid pigment: Accurately weigh 81 g of kaolinite, 81 g of tricobalt tetroxide, and 51 g of aluminum oxide and mix evenly. Cobalt blue hybrid pigment, sample number is S2.

[0042] ②Preparation of superhydrophobic hybrid pigments: Disperse 5 g of the prepared cobalt blue kaolinite hybrid pigments in 30 mL of ethanol, add 1 g of triethanolamine solution, 1 g of water, and 1.5 g of hexadecyltriethoxysilane And stir evenly, after reacting for 16 hours, a superhydrophobic modified cobalt blue kaolinite hybrid pigment is prepared;

[0043] ③Preparation of superhydrophobic heat-resistant coating: In a certain container, add 60g of silicone resin 9801, 5g of modified cobalt blue hybrid pigment, 10g of ceramic powder, 22g of glass fiber and other pigments and fillers, stir for a certain period of time, then add 1g Leveling agent (BYK333), 2g defoamer (BYK024), adjust viscosity, place for aging, spray board, prepare heat-resistant self-cleaning coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com