Extreme-speed air cooling treatment device and method for liquid steel slag

A liquid steel slag and air-cooling technology, which is applied in the field of extremely fast air-cooling devices for liquid steel slag treatment, can solve problems such as pollution, low application value, and low processing efficiency, and achieve the goals of avoiding inert gas impact, wide market application, and optimized logic structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

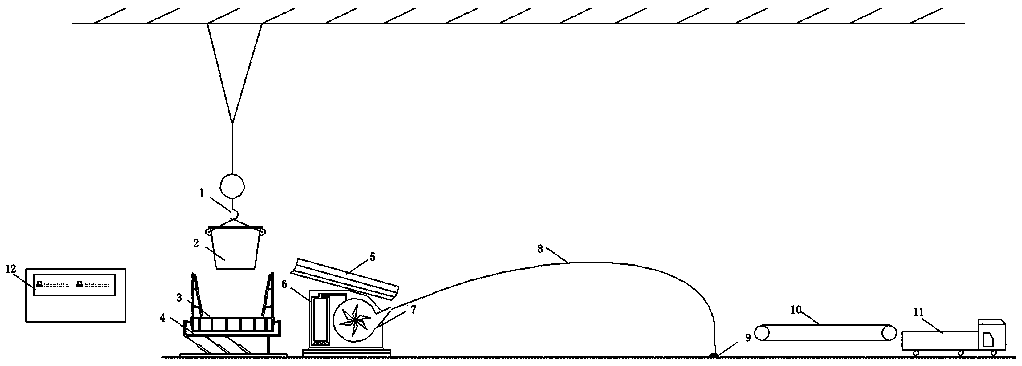

Image

Examples

Embodiment 1

[0027] The constant pressure air system is adjusted according to the instructions of the automatic control platform to match the flow rate of 1T / min liquid steel slag with the constant pressure air flow of 50KPa, and it is sprayed out through the "grid type" nozzle. .

Embodiment 2

[0029] The constant pressure air system is adjusted according to the instructions of the automatic control platform to match the flow rate of 1.3T / min liquid steel slag with the constant pressure air flow of 50KPa, and it is sprayed out through the "grid type" nozzle. .

Embodiment 3

[0031] The constant pressure air system is adjusted according to the instructions of the automatic control platform to match the flow rate of 1T / min liquid steel slag with the constant pressure air flow of 60KPa, which is sprayed out through the "grid type" nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com