Adhesive hydrogel and preparation method thereof

A technology of hydrogel and cationic monomers, which is applied in the field of adhesive hydrogel and its preparation, can solve the problems of unfavorable adhesion, hard gel texture, complicated process, etc., to avoid the toxicity of the gel and improve the adhesion strength , the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention proposes a method for preparing an adhesive hydrogel, comprising the following steps:

[0040] (1) Mix cationic monomers, photoinitiators, anionic components, and water to obtain a precursor solution;

[0041] (2) Degassing the above-mentioned precursor solution;

[0042] (3) irradiating the precursor solution obtained in step (2) with ultraviolet light to initiate the polymerization of cationic monomers, and the produced cationic polymer interacts with anionic components to form an adhesive hydrogel;

[0043] Wherein, the anionic component includes glycosaminoglycan and its derivatives.

[0044] The embodiment of the present invention adopts "one-step method" (homopolymerization of cationic monomers and electrostatic combination with short-chain anionic components) to prepare polyion composite hydrogels, which is different from the high The precursor solution of the charge concentration often leads to the hard texture of the pr...

Embodiment 1

[0073] Example 1 Preparation of Adhesive Hydrogels

[0074] 1) Prepare precursor solution: add acryloyloxyethyltrimethylammonium chloride (cationic monomer), ketoglutaric acid (photoinitiator), deionized water and sodium chondroitin sulfate (anionic component) to In the beaker, stir for 0.5h to obtain a uniform precursor solution.

[0075] Wherein, the total volume of the solution is 10ml, the concentration of the precursor solution is 2.5mol / L, the charge molar concentration ratio of the anion component and the cation component is 0.1, and the concentration of ketoglutaric acid is 0.1% of the concentration of the cationic monomer.

[0076] 2) Degassing of the precursor solution: place the prepared precursor solution in an ultrasonic cleaner, ultrasonically treat it for 1 hour at room temperature, then place the solution in a vacuum oven, and vacuum defoam for 0.5 hours at room temperature and -0.1MPa pressure , to obtain a bubble-free precursor solution.

[0077] 3) UV-in...

Embodiment 2-4

[0078] Example 2-4 Preparation of Adhesive Hydrogels

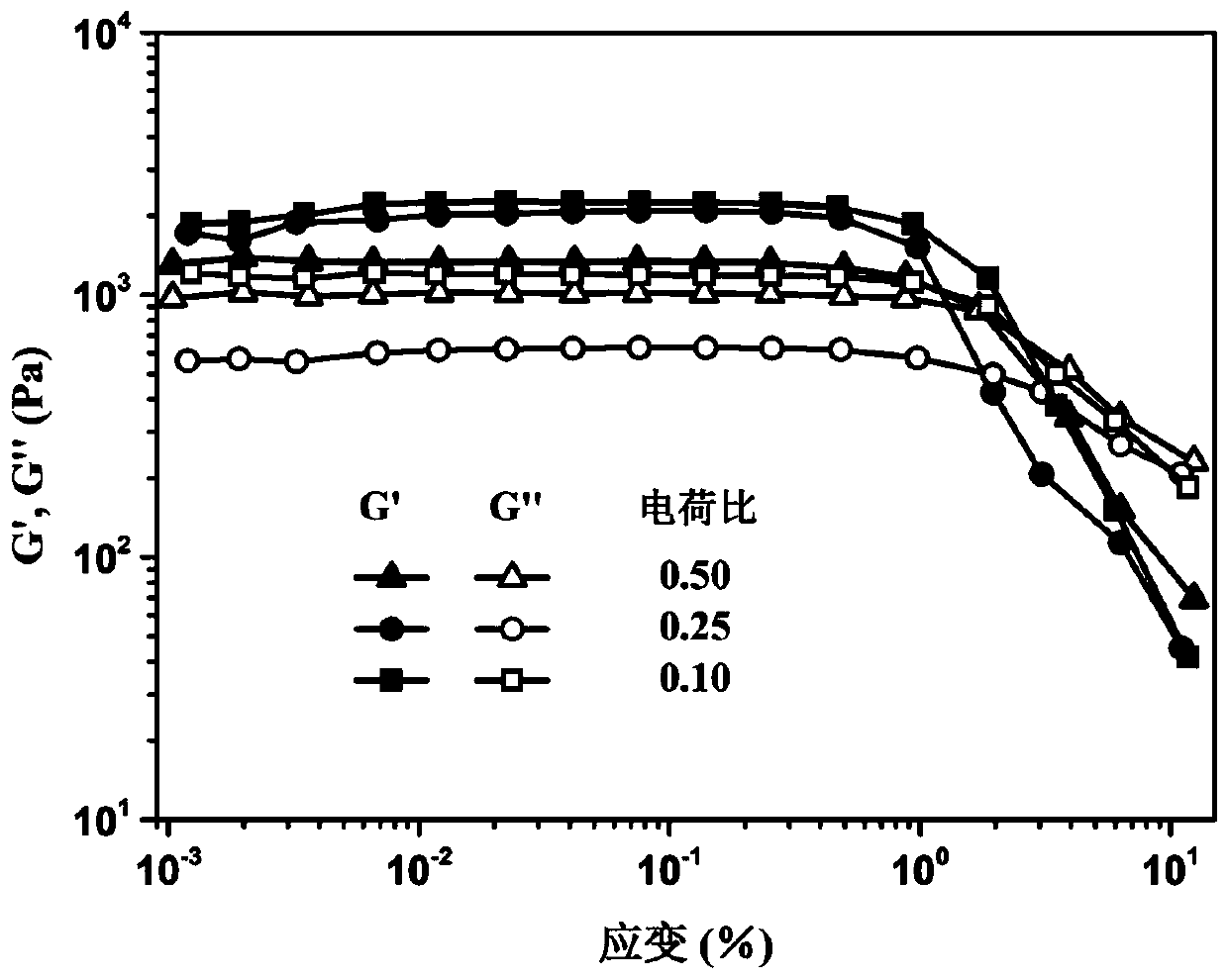

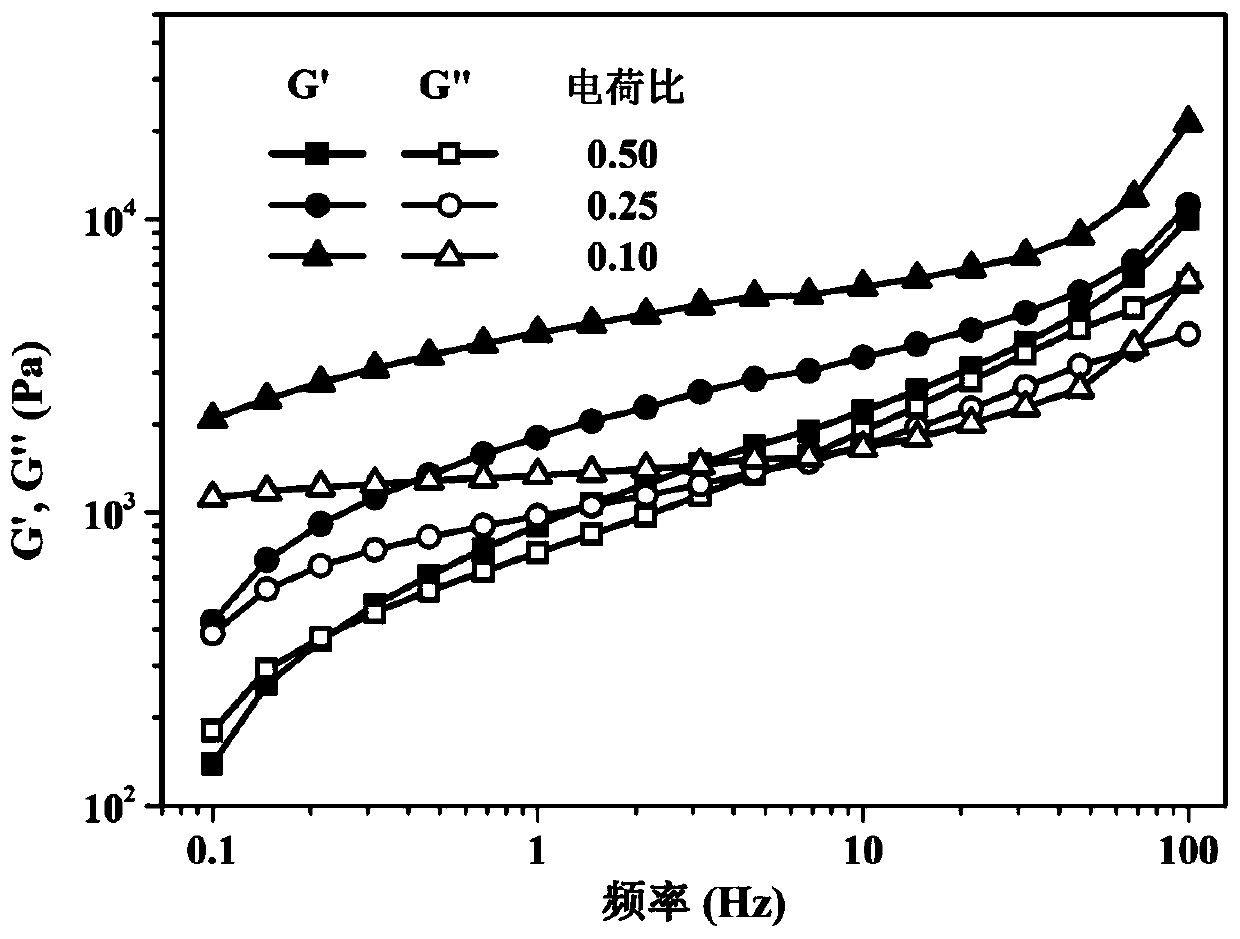

[0079] Same as Example 1, the difference lies in that in Examples 2-4, the molar concentration ratios of charges carried by the anion component and the cation component are 0.25, 0.5, and 1, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com