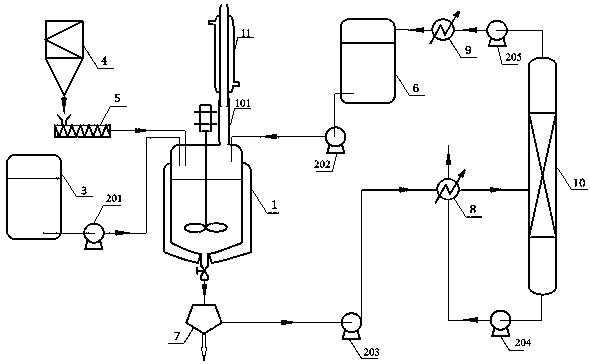

Method for producing urea phosphate with wet-process phosphoric acid as raw material by dilution crystallization

A technology of wet-process phosphoric acid and dissolution and crystallization, which is applied in chemical instruments and methods, preparation of urea derivatives, preparation of organic compounds, etc., can solve the problems of high energy consumption in evaporation and crystallization operations, high viscosity of evaporation crystallization liquid, and high comprehensive production costs problems, achieve the effects of reducing broken and aggregated phenomena, concentrating product particle size distribution, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for producing urea phosphate using wet-process phosphoric acid as a raw material by decompression evaporation coupled with elution and crystallization, and its specific implementation steps are as follows:

[0022] Step 1. Add a certain amount of wet-process phosphoric acid, urea and acetone to the crystallization tank under normal pressure, 50°C and 50 r / min. The H in the wet-process phosphoric acid in the crystallization tank 2 The volume of O is V mL, and the added quality of urea is the P contained in the wet-process phosphoric acid in the crystallization kettle. 2 o 5 0.85 times the mass, the volume of acetone added is (0~0.15) V mL, constant temperature total reflux and stirring for 1 h to obtain the urea phosphate crystallization mother liquor I, the total reflux refers to the complete condensation of the steam generated in the crystallization tank. Return to the crystallization kettle;

[0023] Step 2: Under the conditions of normal pressure, 50°C and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com