Chlorine-containing organic waste gas catalytic combustion catalyst and preparation method thereof

An organic waste gas, catalytic combustion technology, applied in combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst deactivation, and achieve high anti-Cl poisoning ability, strong anti-chlorine poisoning ability, good The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

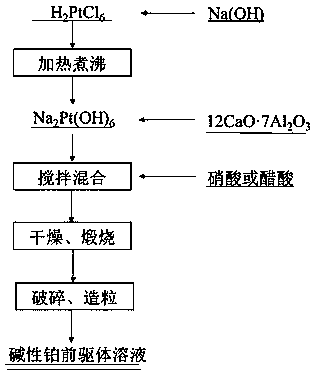

Embodiment 1

[0029] Mix the chloroplatinic acid solution containing 0.85g of metal platinum with the sodium hydroxide solution, adjust the pH=11, heat and boil for 3 hours, add deionized water to prepare a Pt precursor solution with a Pt concentration of 0.1mol / L; then add the compound Oxide heptaaluminate dodecacalcium carrier 999g, mechanically stirred to fully mix the solid and liquid to obtain a mixed slurry; add dilute nitric acid with a concentration of 0.001mol / L to the mixed slurry to adjust the pH of the system to 3, press filter to remove water, The filter cake was dried at a constant temperature of 150°C for 12 hours, calcined at 500°C for 4 hours in an air atmosphere, and granulated to obtain a catalytic combustion catalyst for chlorine-containing organic waste gas, in which the mass of platinum oxide accounted for 0.1% of the total mass of the catalyst.

Embodiment 2

[0031] Mix the chloroplatinic acid solution containing 1.72g of metallic platinum with sodium hydroxide solution, adjust to pH=12, heat and boil for 5 hours, add deionized water to prepare a Pt precursor solution with a Pt concentration of 0.8mol / L; then add Composite oxide heptaaluminate dodecacalcium carrier 998g, mechanically stirred to fully mix the solid and liquid to obtain a mixed slurry; add dilute nitric acid with a concentration of 0.01mol / L to the mixed slurry, adjust the pH of the system to 3, and press filter to remove water , the filter cake was dried at a constant temperature of 150°C for 12 hours, calcined at 650°C for 4 hours in an air atmosphere, and granulated to obtain a catalytic combustion catalyst for chlorine-containing organic waste gas, in which the mass of platinum oxide accounted for 0.2% of the total mass of the catalyst.

Embodiment 3

[0033] Mix the chloroplatinic acid solution containing 2.57g of metallic platinum with sodium hydroxide solution, adjust to pH = 11.5, heat and boil for 4 hours, add deionized water to prepare a Pt precursor solution with a Pt concentration of 0.4mol / L; then add Composite oxide heptaaluminate dodecacalcium carrier 997g, mechanically stirred to fully mix the solid and liquid to obtain a mixed slurry; add acetic acid to the mixed slurry to adjust the pH of the system to 3.5, press filter to remove water, and dry the filter cake at a constant temperature of 150°C Calcined at 500°C for 6 hours in an air atmosphere for 12 hours, and granulated to obtain a catalyst for the catalytic combustion of chlorine-containing organic waste gas, wherein the mass of platinum oxide accounts for 0.3% of the total mass of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com