Metal pillared modified layered manganese Birnessite, preparation and applications thereof

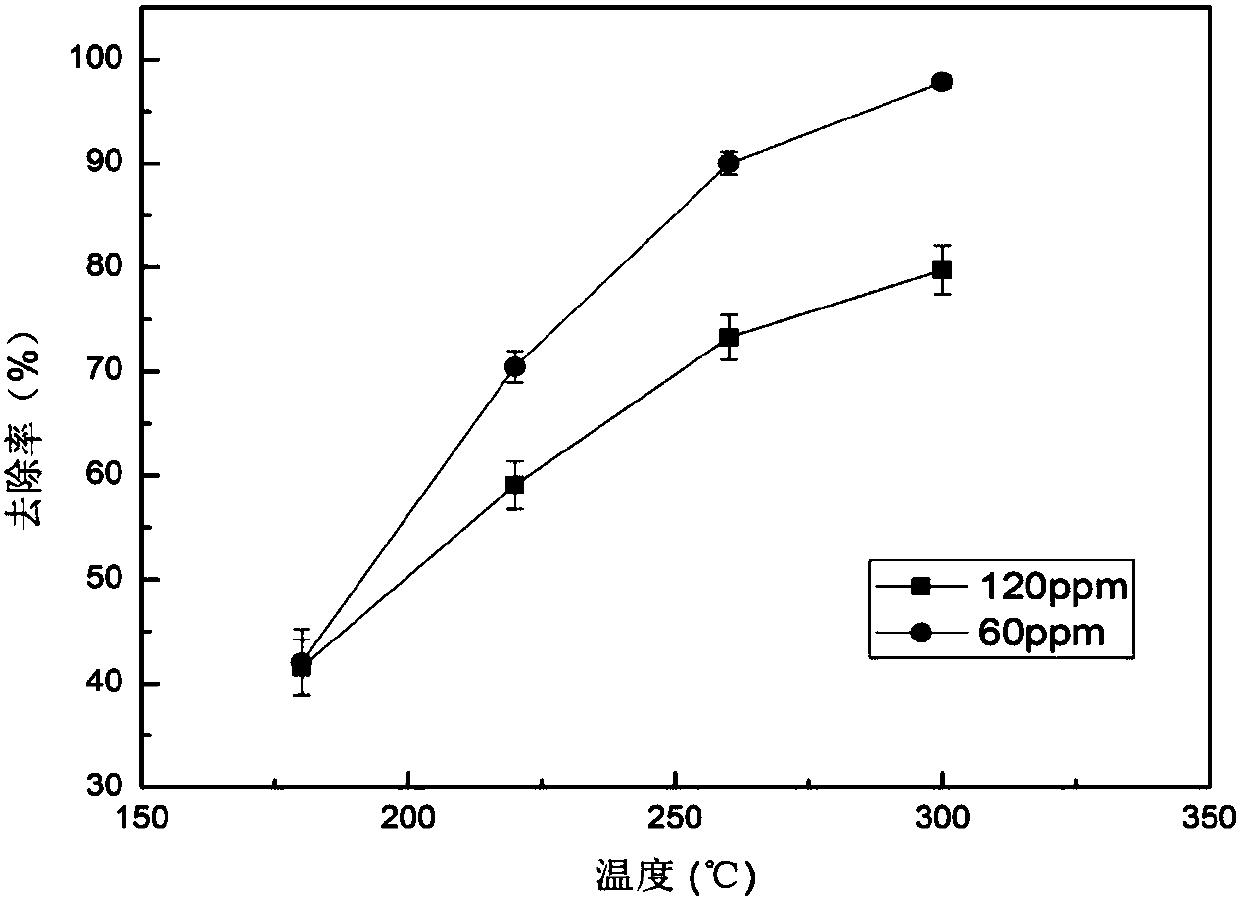

A modified layer and metal pillar technology, applied in the field of metal pillar modified layered manganese Birnessite and its preparation, can solve the problems of easy poisoning and deactivation, increase of industrial cost, etc., achieve strong chlorine poisoning resistance, energy saving, The effect of easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The purpose of this invention is to provide a kind of preparation method of metal pillar modified layered manganese Birnessite, and described preparation method may further comprise the steps:

[0041] Step 1: Preparation of layered manganese precursor, the product is recorded as K-Bir;

[0042] Step 2: carry out hydrogen ion exchange, and the product is recorded as H-Bir;

[0043] Step 3: Perform pillar replacement, and the product is recorded as A-Bir;

[0044] Step 4: Introduce metal ion reaction, the product is recorded as AM-Bir;

[0045] Step 5: calcination, the product is recorded as M-Bir.

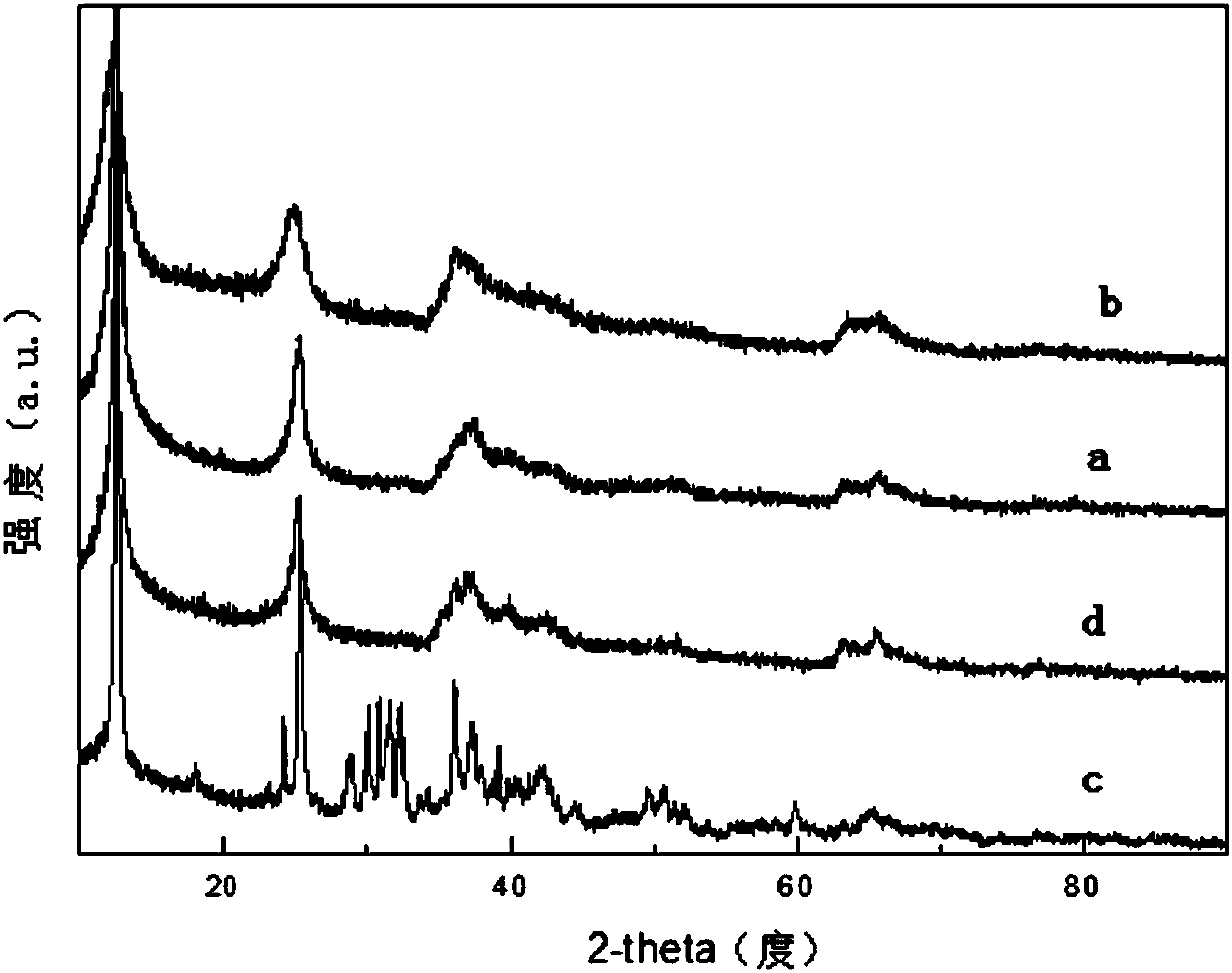

[0046] MnO with layered structure 2 The crystalline compounds are collectively referred to as δ-MnO 2 , the space group belongs to C2 / m, which is a monoclinic system, with [MnO 6 ] formed by common edges. Among them, part of Mn 3+ Ion Substituted Mn 4+ The position of MnO makes it negatively charged, and metal cations and organic macromolecules can enter MnO 2 betwe...

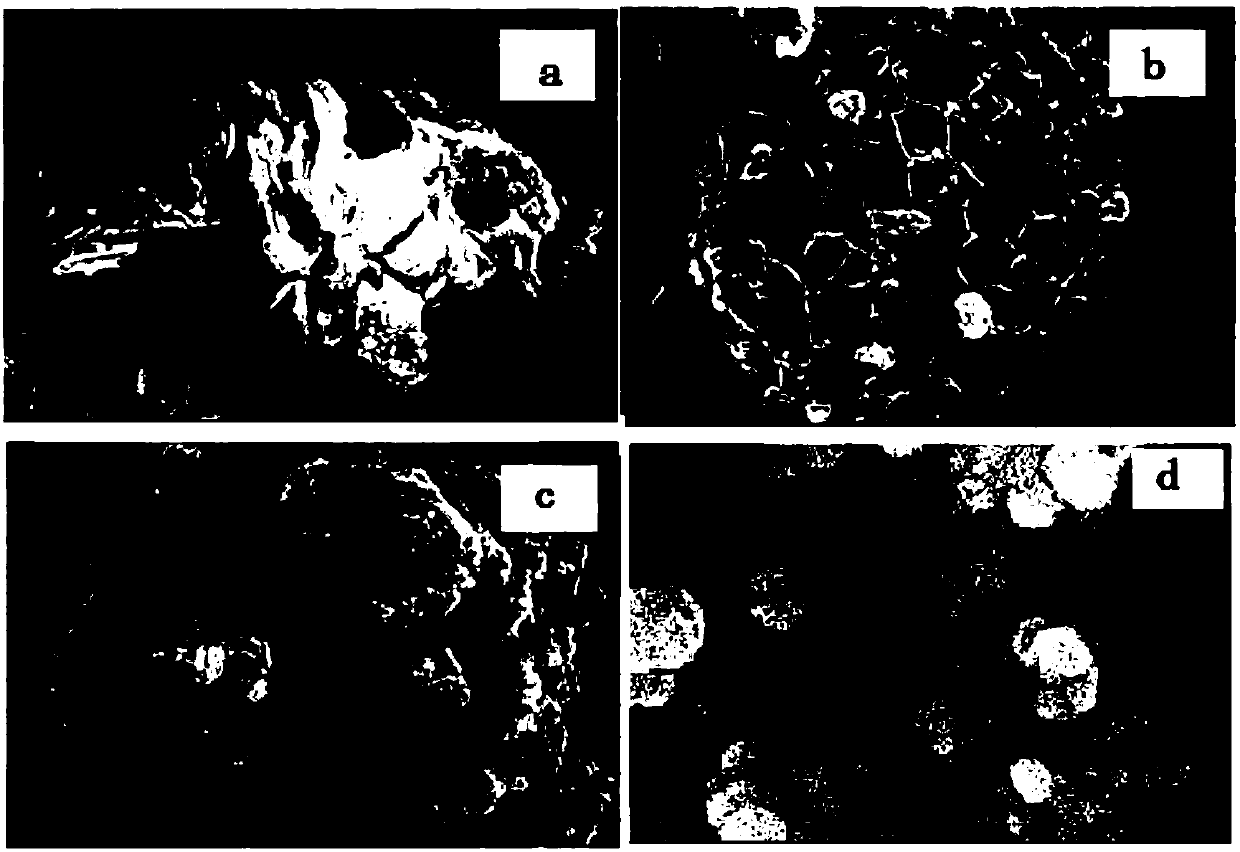

Embodiment 1

[0123] Add 100ml of deionized water to the hydrothermal kettle, then add 1.58g of KMnO 4 Add to the hydrothermal kettle, stir in deionized water for 30min, then add 2ml of 0.15mol / L ammonia water; then react the added raw materials in the hydrothermal kettle at 160°C for 12h, and the reaction ends;

[0124] Filter the solid-liquid mixture of the reaction solution in the hydrothermal kettle, and wash the filter cake with deionized water until the pH of the filtrate is 7 to obtain a filter cake; then dry the filter cake at 80°C for 12 hours to obtain K-Bir;

[0125] The resulting K-Bir was placed in 1M HNO 3 In the solution, the H-Bir was prepared by heating and stirring at 40 °C for 24 h for hydrogen ion exchange;

[0126] The obtained H-Bir was placed in a 0.5mol / L n-octylamine-ethanol solution, the molar ratio of n-octylamine and manganese was 5:1, heated and stirred at a temperature of 45°C for 24h to carry out column replacement, suction filtration, The filter cake was dr...

Embodiment 2

[0130] Add 100ml of deionized water to the hydrothermal kettle, then add 1.58g of KMnO 4 was added to the hydrothermal kettle, stirred in deionized water for 30 min, and then added 2 ml of 0.15 mol / L citric acid; then the added raw materials were reacted in the hydrothermal kettle at 160°C for 12 h, and the reaction ended;

[0131] Filter the solid-liquid mixture of the reaction solution in the hydrothermal kettle, and wash the filter cake with deionized water until the pH of the filtrate is 7 to obtain a filter cake; then dry the filter cake at 80°C for 12 hours to obtain K-Bir;

[0132] The resulting K-Bir was placed in 1M HNO 3 In the solution, the H-Bir was prepared by heating and stirring at 40 °C for 24 h for hydrogen ion exchange;

[0133] The obtained H-Bir was placed in a 0.5 mol / L n-octylamine ethanol solution, the molar ratio of n-octylamine and manganese was 5:1, heated and stirred at 45 °C for 24 h to carry out column replacement, suction filtration, and The fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com