Electrostatic chuck

A technology of electrostatic chuck and electrode layer, which is applied in the direction of holding devices, circuits, discharge tubes, etc. that apply electrostatic attraction, and can solve the problems that the in-plane uniformity of plasma density cannot be fully obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

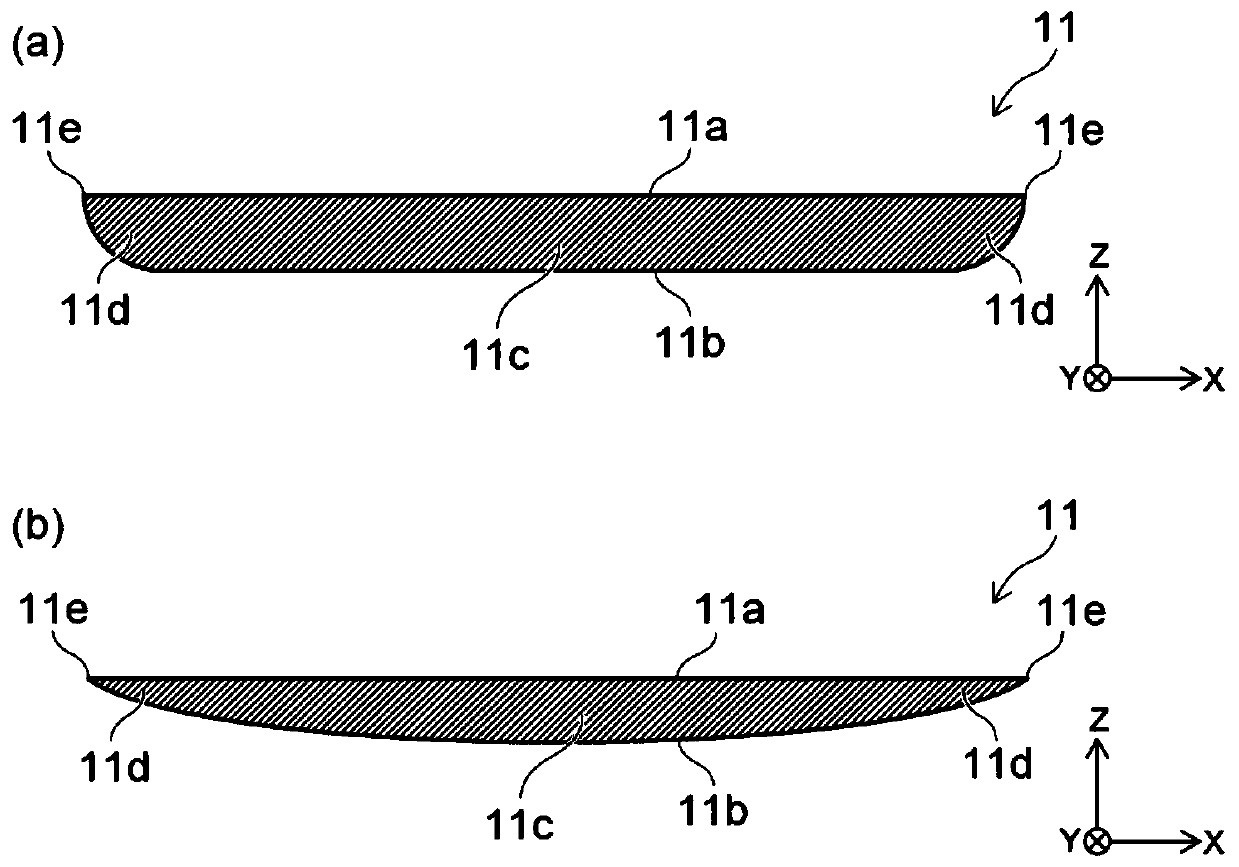

[0079] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each drawing, the same reference numerals are assigned to the same components, and detailed description thereof will be appropriately omitted.

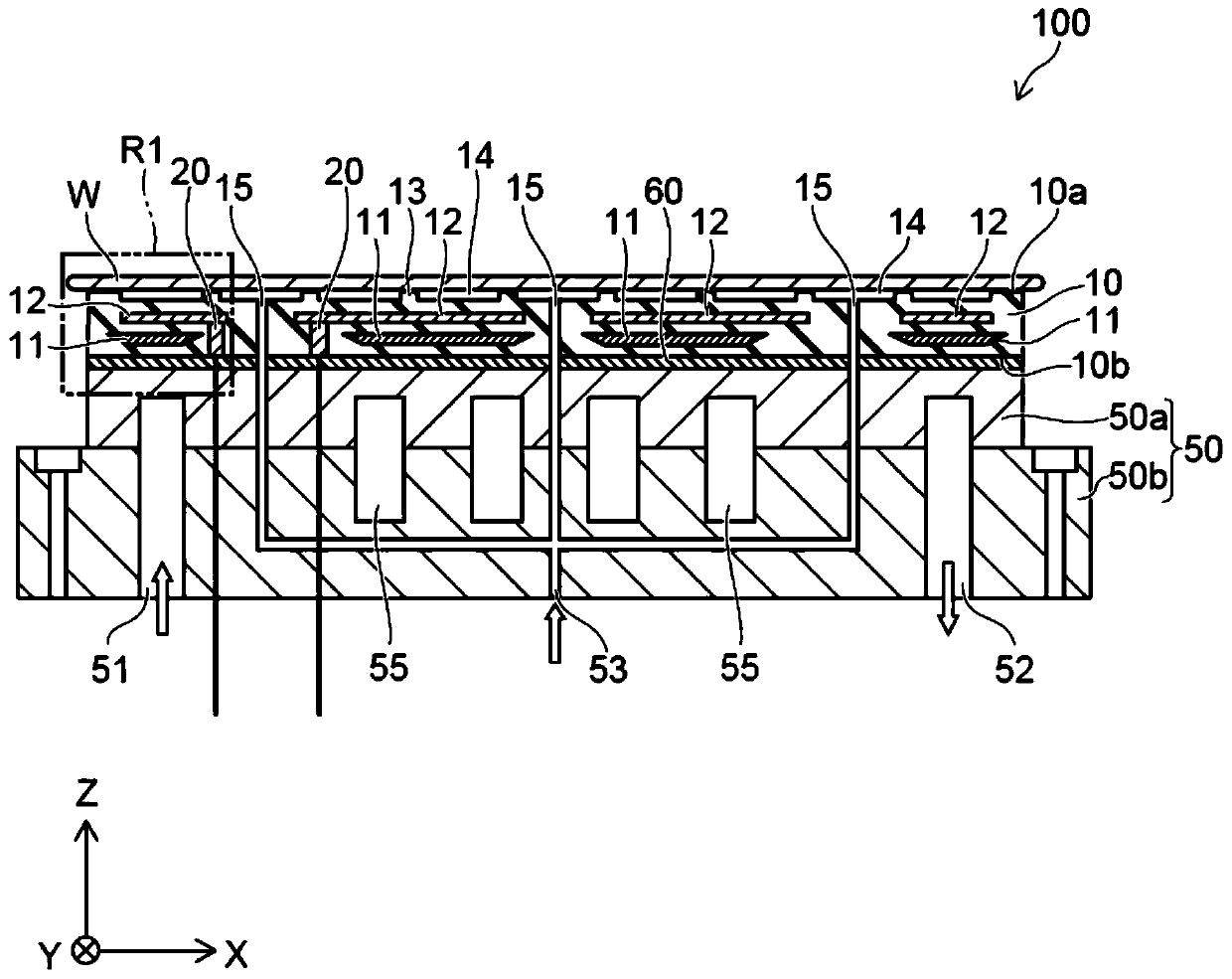

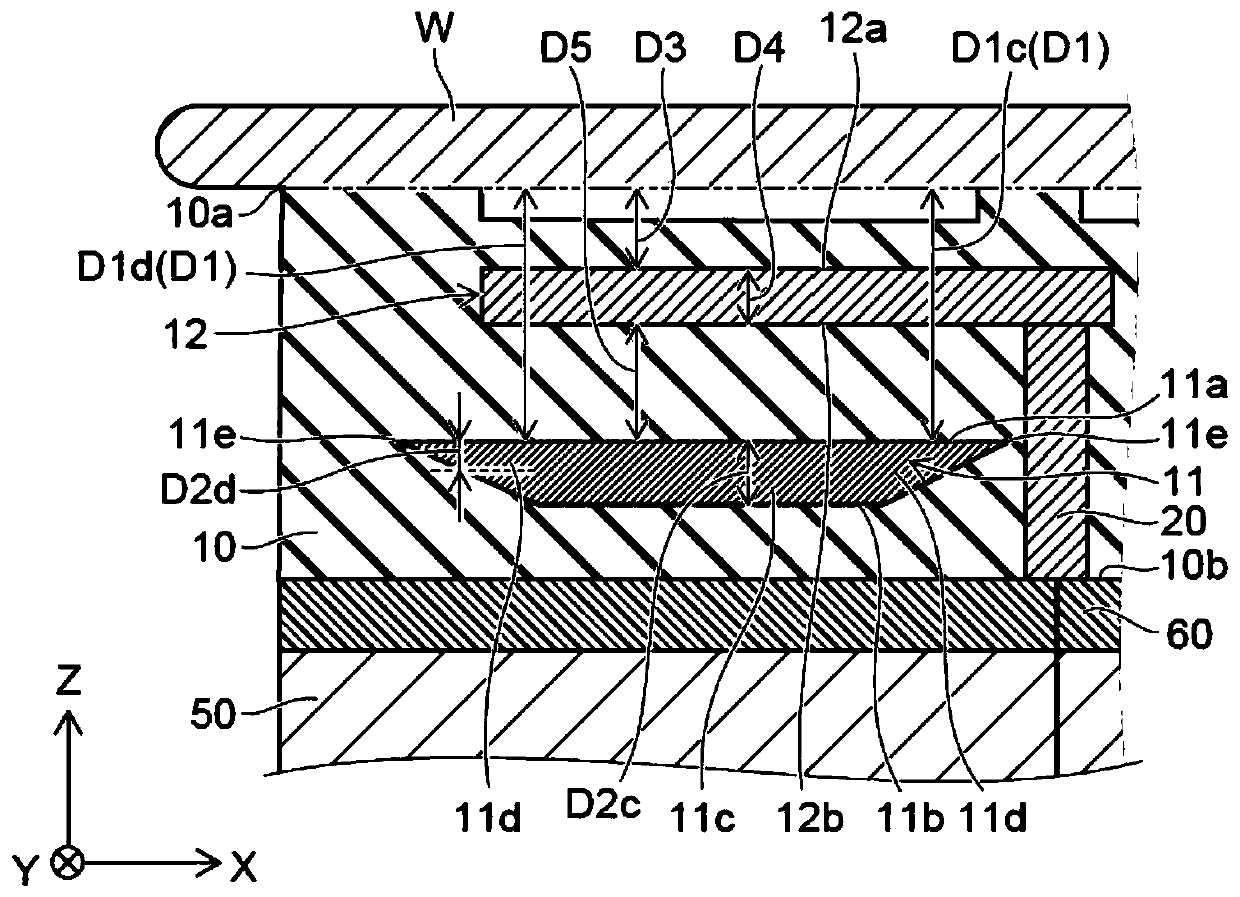

[0080] figure 1 It is a schematic cross-sectional view illustrating an electrostatic chuck according to an embodiment.

[0081] Such as figure 1 As shown, the electrostatic chuck 100 includes a ceramic dielectric substrate 10 , a first electrode layer 11 , a second electrode layer 12 , and a base plate 50 .

[0082] The ceramic dielectric substrate 10 is, for example, a plate-shaped base material formed of sintered ceramics. For example, the ceramic dielectric substrate 10 contains alumina (Al 2 o 3 ). For example, the ceramic dielectric substrate 10 is formed of high-purity alumina. The concentration of alumina in the ceramic dielectric substrate 10 is, for example, 90 mass % or more and 100 mass % or less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com