Preparation method and application of indanthrene functionalized graphene three-dimensional network structure composite material

A technology of indanthrene and network structure, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of low power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

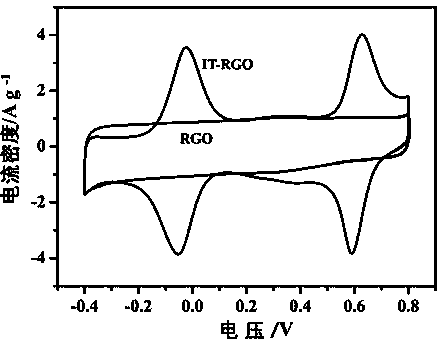

[0031] 1. Preparation of IT-RGO-1 composite material:

[0032] Disperse 0.1 g of graphite oxide (GO) in 15 mL of DMF, stir for 1 h, and then sonicate for 4 h; dissolve 0.02 g of indanthrene in 10 mL of secondary water, and stir for 2 h; Pour into the indanthrene solution, stir for 1 h, and then ultrasonically treat for 4 h; then transfer the mixed solution to a 30 mL high-temperature reactor, and react at 180°C for 720 min. The reaction product is soaked in secondary water for several times until the solution becomes colorless and transparent, and finally the product is freeze-dried, which is the IT-RGO-1 composite material;

[0033] 2. Preparation of IT-RGO-1 composite electrode: 4 mgIT-RGO-1 and 0.7 mg acetylene black (mass ratio 85:15) were thoroughly ground in a mortar, and then 0.4 mL0. 25 wt% Nafion solution, ultrasonically dispersed to form a suspension; then use a pipette gun to measure 6 μL of the above suspension and drop it on the surface of the glassy carbon elect...

Embodiment 2

[0036] 1. Preparation of IT-RGO-2 composite material:

[0037] 0.1 gGO was dispersed in 15 mL of DMF, stirred for 1 h, and then sonicated for 4 h. Dissolve 0.05 g of indanthrene in 10 mL of secondary water and stir for 2 h; add the ultrasonically treated GO dispersion into the indanthrene solution, stir for 1 h, and then sonicate for 4 h; then transfer the mixed solution to In a 30 mL high-temperature reactor, react at 180°C for 720 min. The reaction product was soaked in secondary water for several times until the solution became colorless and transparent, and finally the product was freeze-dried to obtain the IT-RGO-2 composite material;

[0038] 2. The preparation of the IT-RGO-2 composite electrode is the same as in Example 1;

[0039] 3. Electrochemical performance test: the detection method is the same as in Example 1; the detection result: when the current density is 1 A g -1 , the specific capacitance of the electrode material can reach 327Fg -1 .

Embodiment 3

[0041] 1. Preparation of IT-RGO-3 composite material:

[0042] Disperse 0.1 g graphite oxide (GO) in 15 mL of DMF, stir for 1 h, then sonicate for 4 h; dissolve 0.07 g of indanthrene in 10 mL of secondary water, stir for 2 h; disperse GO after ultrasonic treatment The liquid was put into the indanthrene solution, stirred for 1 h, and then ultrasonically treated for 4 h; then the mixed solution was transferred to a 30 mL high-temperature reactor, and reacted at 180°C for 720 min. The reaction product was soaked in secondary water for several times until the solution became colorless and transparent, and finally the product was freeze-dried to obtain the IT-RGO-3 composite material;

[0043] 2. The preparation of the IT-RGO-3 composite electrode is the same as in Example 1;

[0044] 3. Electrochemical performance test: the detection method is the same as in Example 1; the detection result: when the current density is 1 A g -1 , the specific capacitance of the electrode materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com