High-temperature tensile test clamp suitable for steel wire with special-shaped section

A technology of tensile test and special-shaped section, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of inaccurate test results, large damage to the tested material, and errors, etc., to achieve reduction Small error, avoid damage, improve the effect of experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

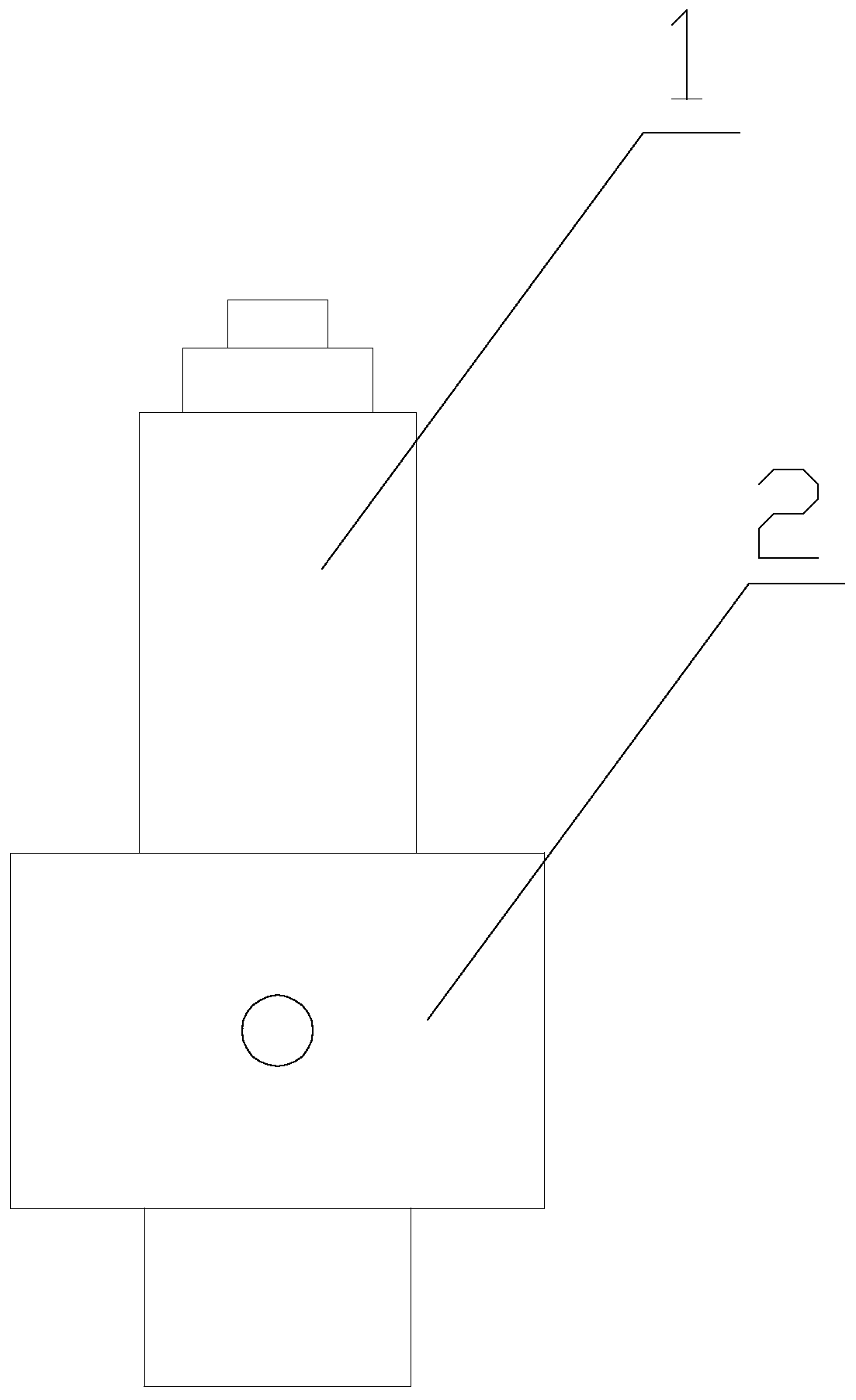

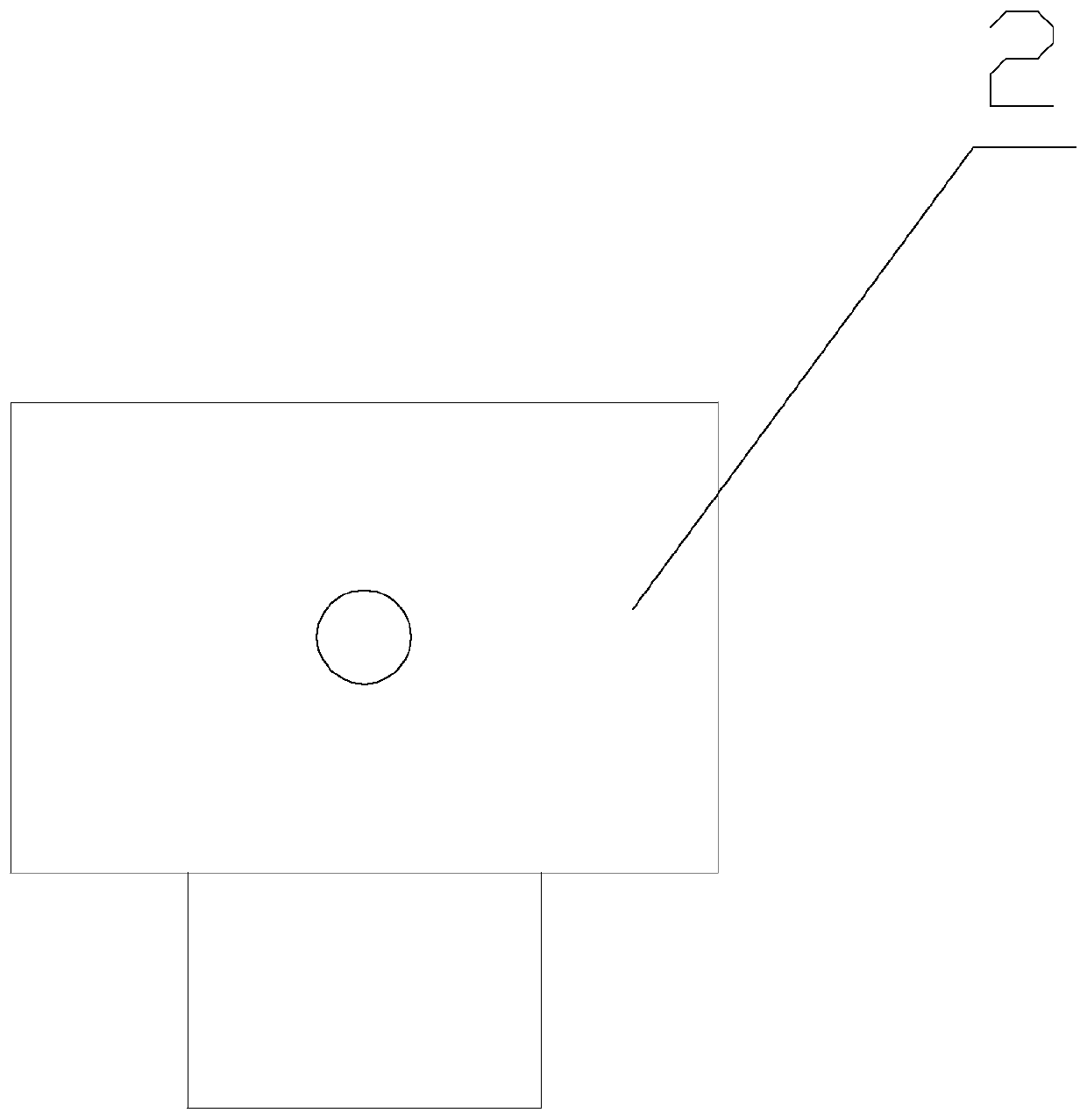

[0021] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, a high-temperature tensile test fixture suitable for special-shaped cross-section steel wires described in this embodiment includes a collar 1 and a chuck 2;

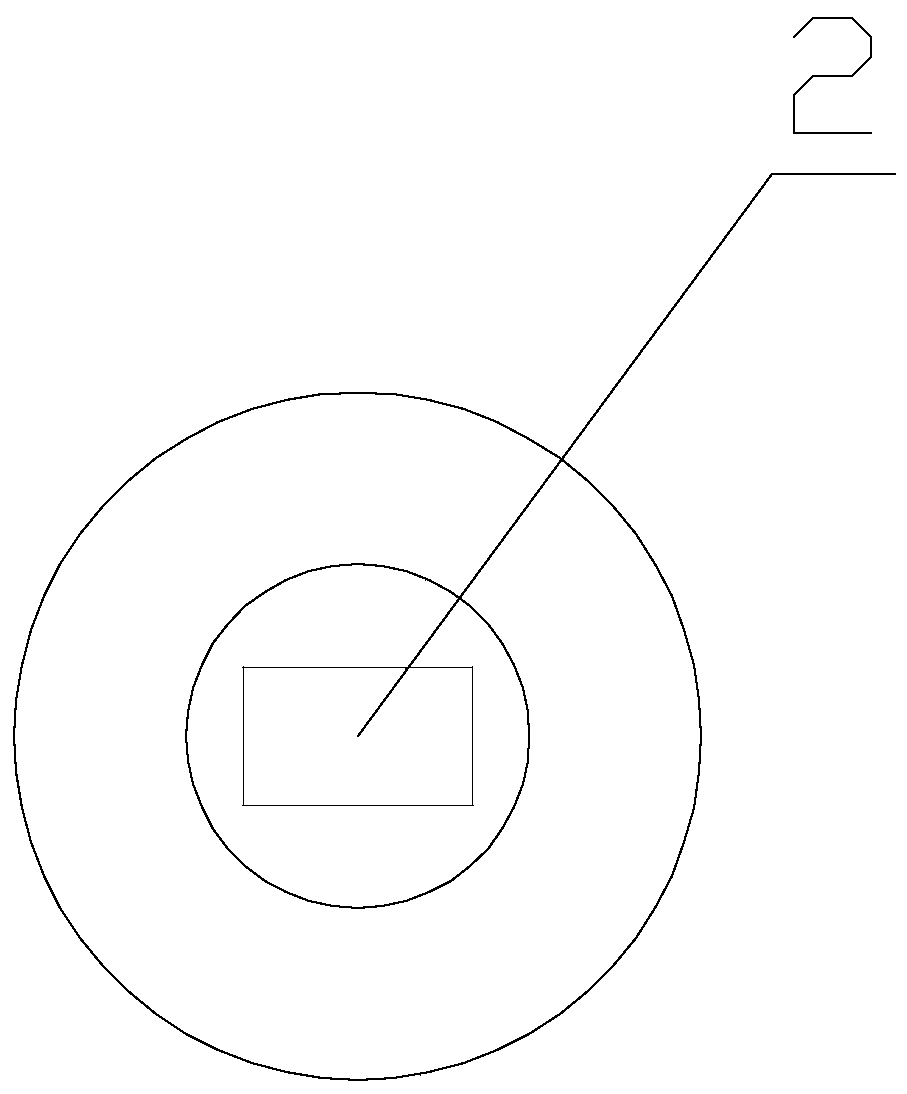

[0022] The chuck 2 is cylindrical, and the center of the lower surface of the chuck 2 is provided with a boss, and the center of the upper surface of the chuck 2 is provided with a square through hole, and the outer wall of the chuck 2 along the circumferential direction is uniformly provided with two pin holes, and the two pin holes are symmetrically arranged, the collar 1 is a cuboid with a cavity, and the top of the collar 1 is provided with n square bosses, n is a positive integer, and the two sides of the collar 1 are symmetrically arranged Multiple sets of through holes, the collet 2 passes through one end of the collar 1, and is fixedly connected by a pin;

[0023] In this specific embodiment, when in use, one e...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination Figure 4 Describe this embodiment, this embodiment is a further limitation on the fixture described in the first specific embodiment, a high-temperature tensile test fixture suitable for special-shaped cross-section steel wire described in this embodiment, the collar 1 The number n of square bosses, 1≤n≤3.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 2 and Figure 4 Describe this embodiment, this embodiment is a further limitation on the fixture described in the second specific embodiment, a high temperature tensile test fixture suitable for special-shaped cross-section steel wire described in this embodiment, the collar 1 and The material of chuck 2 is high temperature alloy 4169;

[0026] In this specific embodiment, the collar 1 and chuck 2 are both made of superalloy 4169. Under high temperature (600-1000 degrees) conditions, ordinary steel has almost no strength due to the temperature softening effect, and high temperature resistant materials must be selected. High temperature alloy 4169 is cheaper than other materials (such as high-temperature alloy GH4049, etc.), and its melting point is about 1400 degrees, so it can be used to make high-temperature tensile fixtures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com