A device and method for measuring thermal focal length of laser medium

A technology for measuring lasers and laser media, applied in the field of lasers, can solve problems such as differences in thermal focal length, inaccurate measurement results, and difficulty in determining the specific position of the focus, achieving the effects of fast layout, simple cat-eye structure, and reduced use space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

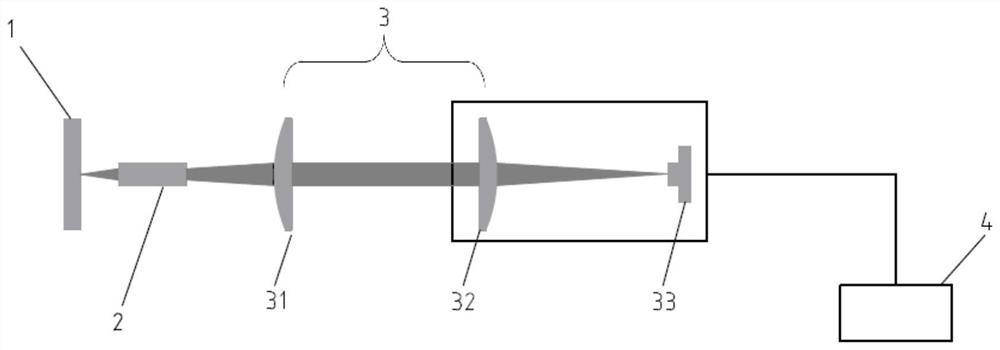

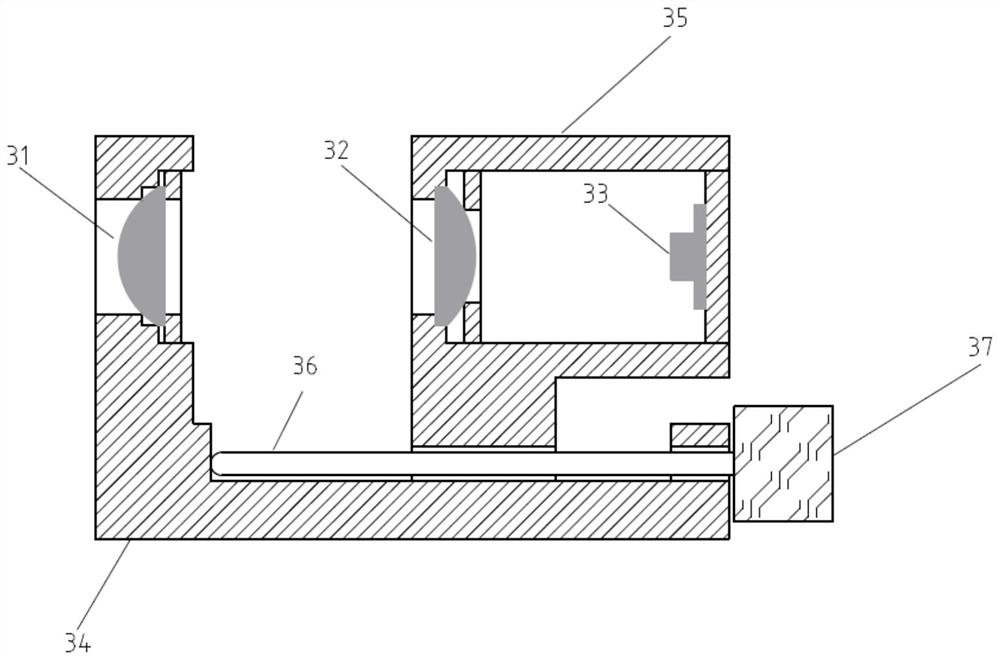

[0030] The present invention mainly consists of a pump source for outputting pump light, a rear reflector 1 arranged in sequence on the optical axis of the pump light, a laser medium to be measured 2, a cat's eye module 3 and a photodetector 33, and a cat's eye for installing module and photodetector mounting frame, such as figure 1 As shown; the cat's eye module is the core component of this measuring device, and its installation diagram on the mounting frame is shown in figure 2 shown. The working principle and usage flow of the device will be described below in conjunction with the accompanying drawings.

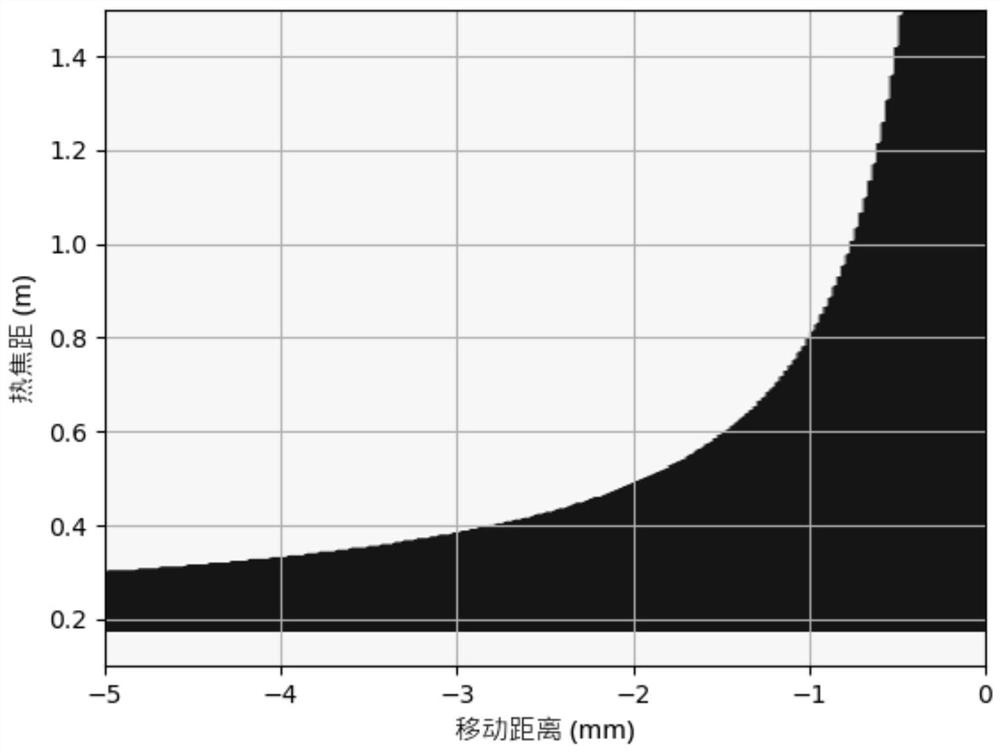

[0031] The basic idea of the invention is to test the thermal lens focal length of the laser medium by utilizing the correlation between the stability of the resonant cavity and the thermal lens focal length of the laser medium.

[0032] like figure 1 As shown, what is different from the prior art is that the present invention uses a cat's-eye module 3 composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com