Pressure-regulating type perfusion plugging machine

A pressure-regulating and leaking machine technology, which is applied in building maintenance, construction, building construction, etc., can solve structural compressive strength and shear force changes, concrete structure damage, and difficult cleaning, etc., to reduce hazards , avoid waste, reduce the effect of cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

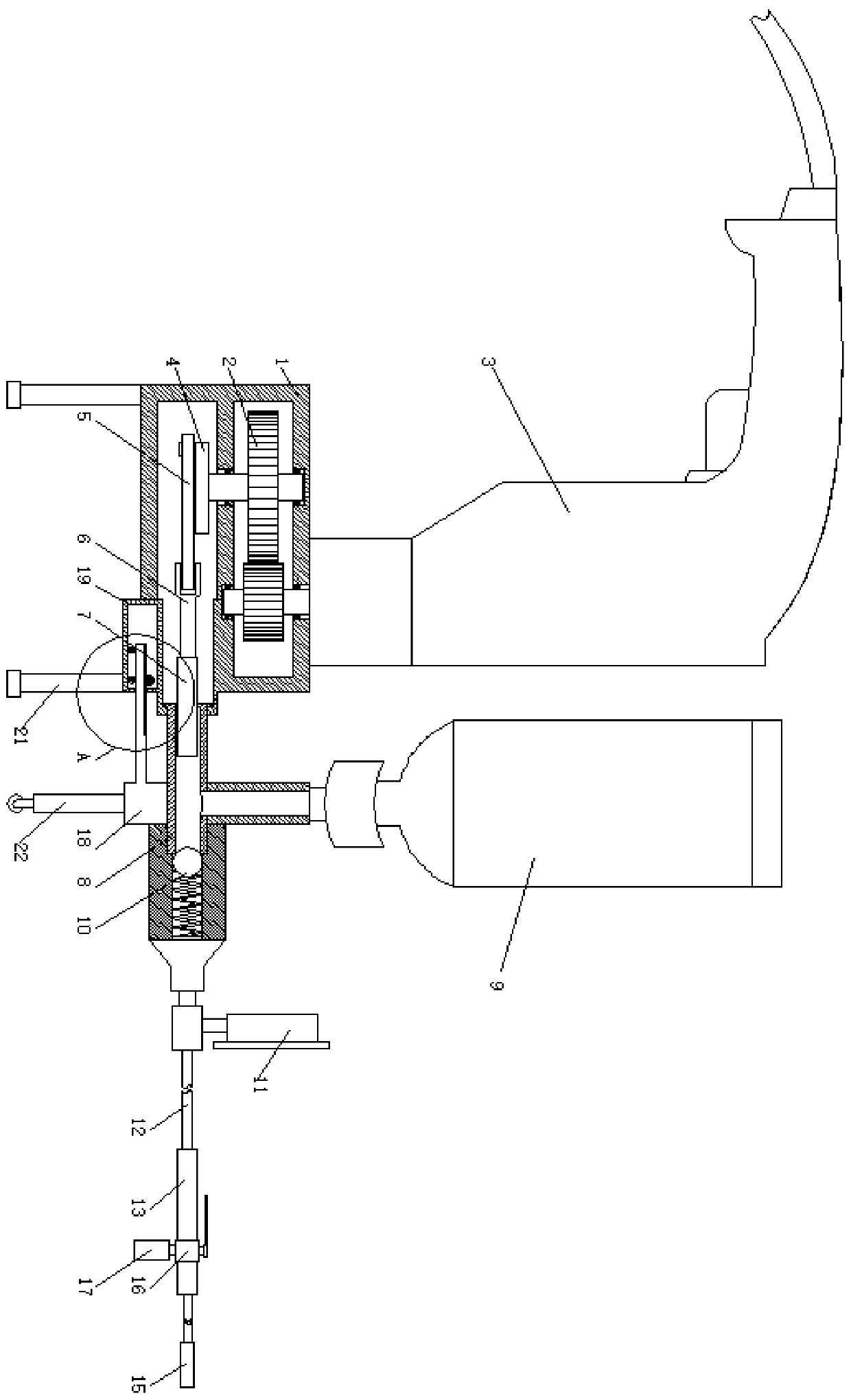

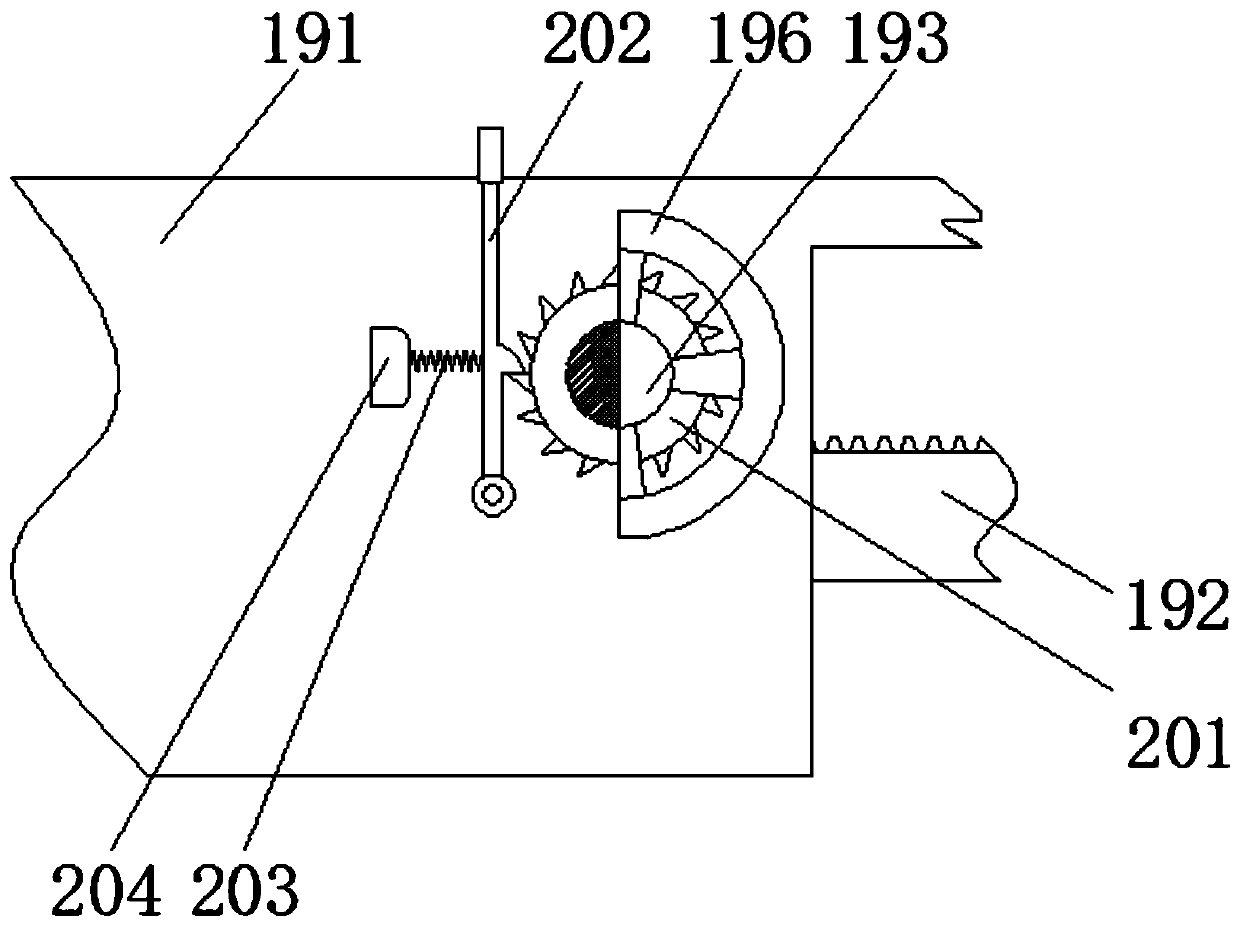

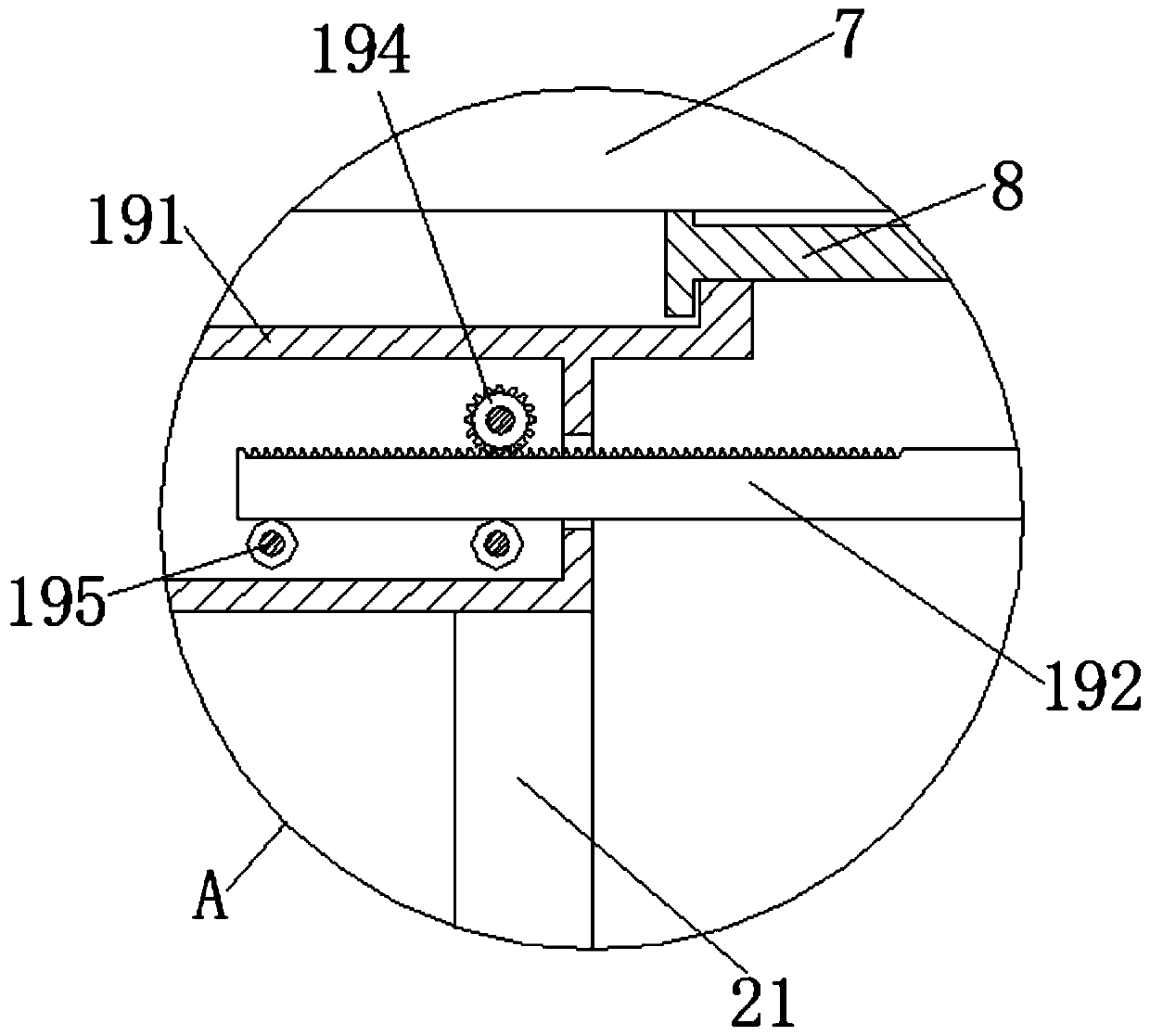

[0021] see Figure 1-3 , a pressure-regulating perfusion plugging machine, including a gearbox 1, a gear set 2, a hand-held motor 3, a cam turntable 4, a connecting rod 5, a movable pull rod 6, a piston rod 7, a copper piston sleeve 8, a barrel 9, a stopper return device 10, pressure gauge 11, conveying pipe 12, metal pipe 13, butter head 15, two-way switch 16, receiving bottle 17, fixed seat 18, regulating device 19, limiting device 20, supporting leg 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com