A nanocrystalline silicon oxide film and a photoresist-like silicon oxide material prepared therefrom

A technology of crystalline silicon oxide and colloidal silicon oxide, which is applied in the field of microelectronics and solar cells, can solve problems such as pollution in the deposition process, achieve the effects of simplifying the preparation process, reducing the deposition temperature, and overcoming the incompatible defects exposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

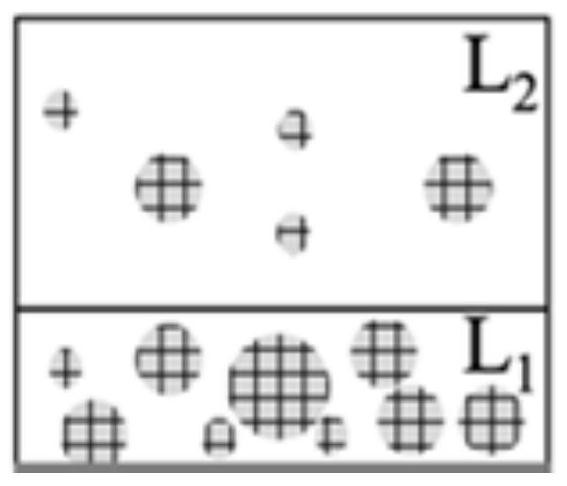

[0048] like figure 1 As shown, a nanocrystalline silicon oxide film, the nanocrystalline silicon oxide film is a multi-layer film formed by embedding silicon nanocrystals in a hydrogenated amorphous silicon oxide matrix, and the multi-layer film sequentially includes L1 layer and For the L2 layer, the refractive index of the L1 layer is 2.3 at 600 nm, and the refractive index of the L2 layer is 1.6 at 600 nm; the thickness of the L1 layer is 50 nm, and the thickness of the L2 layer is 90 nm; among them, the volume fraction of silicon nanocrystals in the L1 layer larger than the volume fraction of silicon nanocrystals in the L2 layer.

Embodiment 2

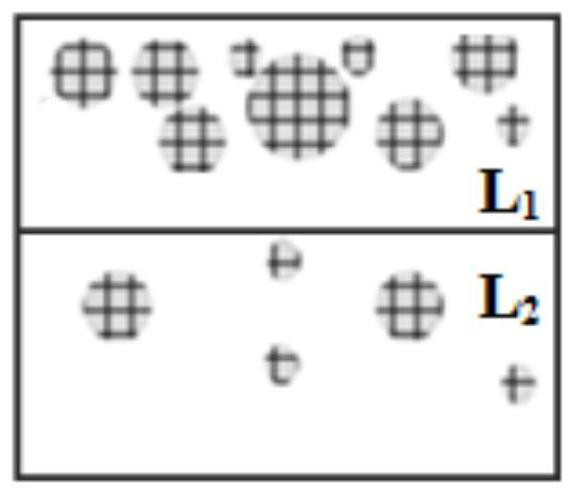

[0050] like figure 2 As shown, a nanocrystalline silicon oxide film, the nanocrystalline silicon oxide film is a multi-layer film formed by embedding silicon nanocrystals in a hydrogenated amorphous silicon oxide matrix, and the multi-layer film sequentially includes L2 layer and L1 layer, the refractive index of L1 layer is 2.9 at 600 nm, and the refractive index of L2 layer is 1.8 at 600 nm; the thickness of L1 layer is 60 nm, and the thickness of L2 layer is 80 nm; among them, the volume fraction of silicon nanocrystals in L1 layer is larger than the volume fraction of silicon nanocrystals in the L2 layer.

Embodiment 3

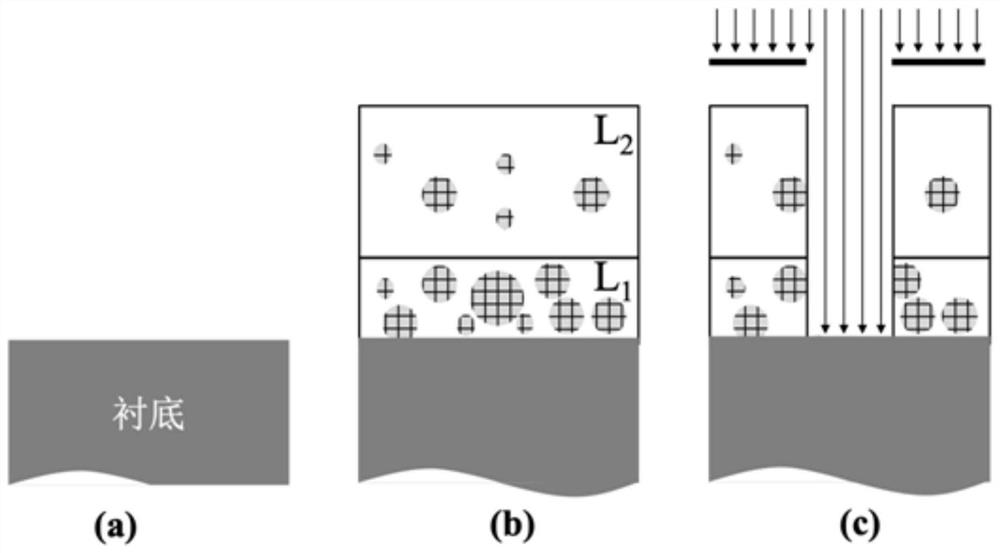

[0052] like image 3 As shown, a photoresist-like silicon oxide, the preparation method of which comprises the following steps:

[0053] Prepare glass substrates (Corning 1737) as image 3 (a);

[0054] First deposit the L1 layer on the substrate, deposition temperature: 150°C, pressure: 2.0 Torr, power density: 100mW / cm 2 , SiH 4 : 12SCCM, H 2 : 200SCCM, CO 2 : 5SCCM, thickness is 50nm; then deposit L2 layer on L1 layer, temperature: 150℃, pressure: 2.0Torr, power density: 100mW / cm 2 , SiH 4 : 12SCCM, H 2 : 200SCCM, CO 2 : 15SCCM with a thickness of 90nm; such as image 3 (b), wherein the refractive index n1 of the L1 layer is 2.3 (600 nm), and the refractive index n2 of the L2 layer is 1.6 (600 nm);

[0055] Ultraviolet laser ablation: Align the mask according to the desired pattern, and then perform laser exposure to obtain a photoresist-like silicon oxide material, such as image 3 (c).

[0056] The absorbance of the above nanocrystalline silicon oxide bilayer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com