Preparation method of heavy metal soil repairing material in paddy field based on biocarbon blending fertilizer

A soil remediation and biochar technology, applied in the field of soil remediation, can solve the problems of limited crop growth promotion ability, poor comprehensive treatment effect of paddy fields, lack of nutrients in biochar, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

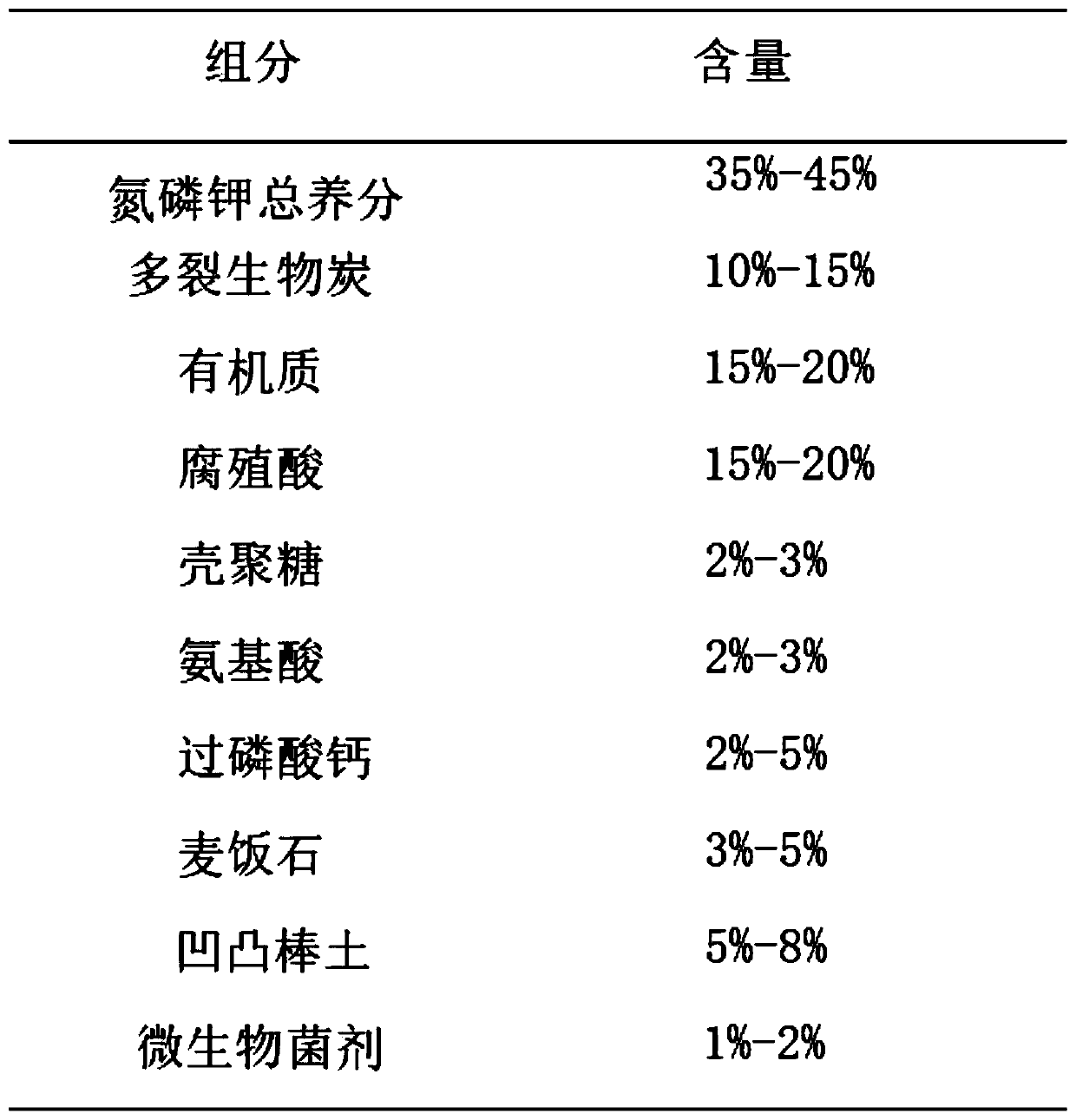

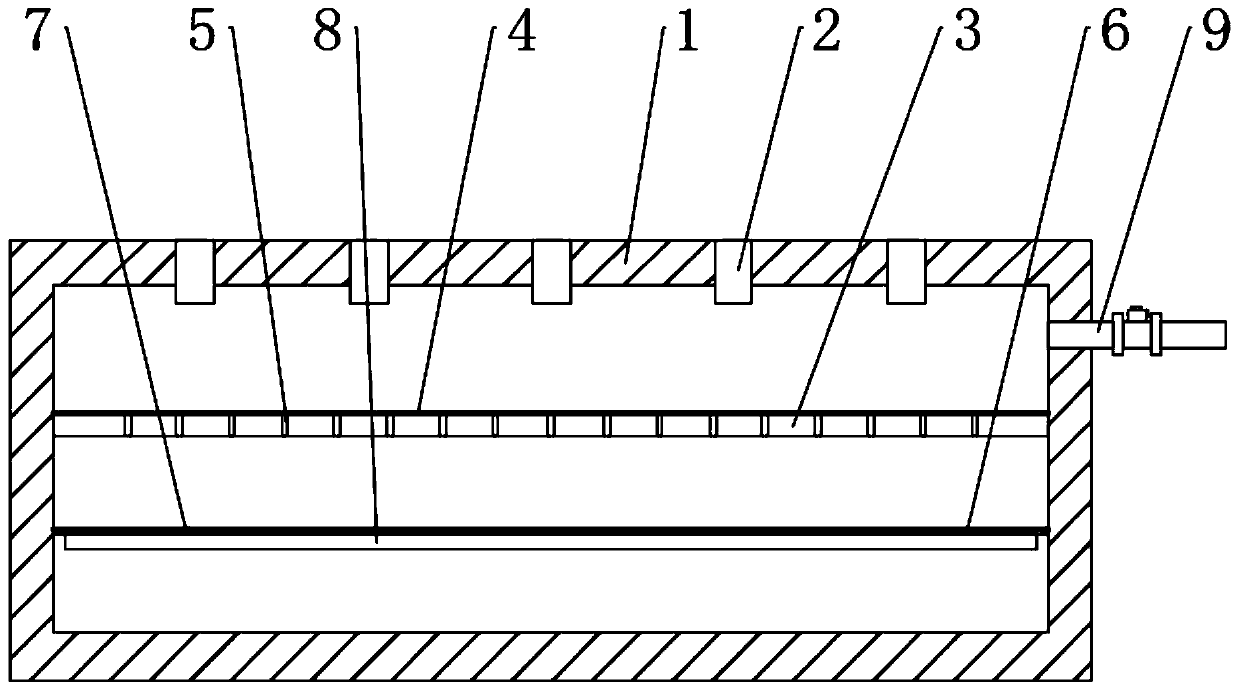

[0049] see figure 1 , a heavy metal soil remediation material for paddy fields based on biochar blended fertilizer, including the following raw materials: 40% of total nutrients of nitrogen, phosphorus and potassium, 10% of multi-fissive biochar, 18% of organic matter, 15% of humic acid, chitosan 3%, amino acid 2%, superphosphate 2%, medical stone 3%, attapulgite 6% and microbial agent 1%.

[0050] During the preparation, the microbial agent was weighed and sprayed evenly on the multi-fisted biochar. During the spraying process, the multi-fisted biochar was stirred and mixed, and after the spraying was completed, it was left to stand at room temperature for 2 hours; Polyacid, chitosan, amino acid, superphosphate, medical stone and attapulgite were mixed with the multi-crack biochar sprayed with microbial agent, and placed in a mixer for stirring at a speed of 60r / min, and the stirring time was 45 minutes to get the mixture; take the mixture and put it in the disc granulator, ...

Embodiment 2

[0062] A heavy metal soil restoration material for paddy fields based on biochar blended fertilizer, including the following raw materials: 40% of total nutrients of nitrogen, phosphorus and potassium, 15% of multi-fissive biochar, 15% of organic matter, 15% of humic acid, and 2% of chitosan %, 2% amino acid, 2% superphosphate, 3% medical stone, 5% attapulgite and 1% microbial agent.

[0063] All the rest are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com