Steel welding flux-cored wire used for high heat input welding and preparing method and welding method of steel welding flux-cored wire

A technology for high-energy welding and flux-cored welding wire, which is applied in welding/welding/cutting items, welding equipment, welding equipment, etc., and can solve the problems of low mass percentage of flux-cored welding wire, fast consumption of flux-cored welding wire, and deterioration of welding quality. , to achieve the effect of good apparent quality, increased electrical conductivity and reduced water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

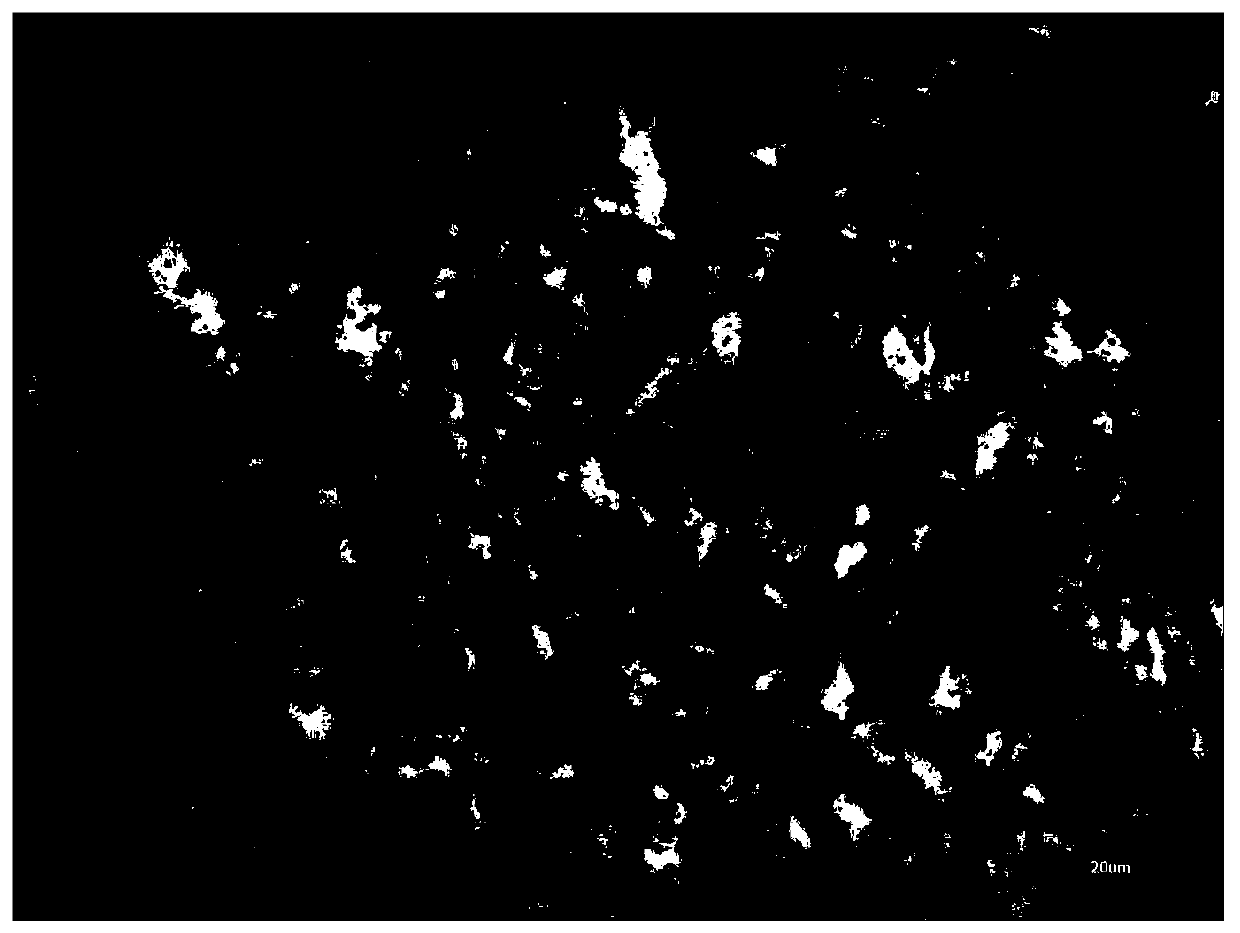

Image

Examples

Embodiment 1

[0051] A steel welding flux-cored wire for large heat input welding, which can be applied to single-wire and multi-wire open-arc welding of medium-thick plates with a heat input of 300-450KJ / cm. The flux-cored wire includes flux-core materials and The carbon steel strip sheath wrapping the drug core material, the drug core material includes: C is 0.06wt%, Si is 0.3wt%, Mn is 1.6wt%, Ni is 2.0wt%, B is 0.01wt% , Ti is 0.01wt%, Nb is 0.1wt%, N is 0.01wt%, and the balance is Fe and unavoidable impurities.

[0052] The carbon steel strip sheath is an SPCC carbon steel strip with a thickness of 0.7mm and a width of 10.2mm.

[0053] The drug core material also includes Co, and the content of Co is 0-0.2wt%.

[0054] The drug core material also includes 1.2-2wt% Fe 3 o 4 .

[0055] The drug core material also includes 0.2-0.3 wt% of rare earth elements.

[0056] The drug core material also includes 0.4-0.5wt% NaF.

[0057] The drug core material also includes 1-1.5wt% V.

[00...

Embodiment 2

[0098] In this embodiment, the composition of the drug core material is adjusted so that C is 0.08wt%, Si is 0.3wt%, Mn is 1.6wt%, Ni is 2.2wt%, B is 0.01wt%, Ti is 0.01wt%, and Nb is 0.08wt%, N is 0.01wt%, and the balance is Fe and unavoidable impurities.

[0099] With the above flux core material composition and welding method as in Example 1, no heat treatment is performed after welding, the welding input energy is 310KJ / cm, the tensile strength of the weld seam is 760MP, and the impact energy at -40°C is A kv ≥72J.

Embodiment 3

[0101] In this embodiment, the composition of the drug core material is adjusted so that C is 0.10wt%, Si is 0.3wt%, Mn is 1.6wt%, Ni is 2.4wt%, B is 0.01wt%, Ti is 0.01wt%, and Nb is 0.06wt%, N is 0.01wt%, and the balance is Fe and unavoidable impurities.

[0102] With the above flux core material composition and welding method as in Example 1, no heat treatment is performed after welding, the welding input energy is 310KJ / cm, the tensile strength of the weld is 800MP, and the impact energy A at -40°C kv ≥47J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com