A remote intelligent collector and its working method

A technology of intelligent collection and collection, which is applied in current collectors, instruments, volume measurement, etc., can solve the problems of poor signal and data upload failure, etc., to reduce the risk factor, reduce power consumption, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

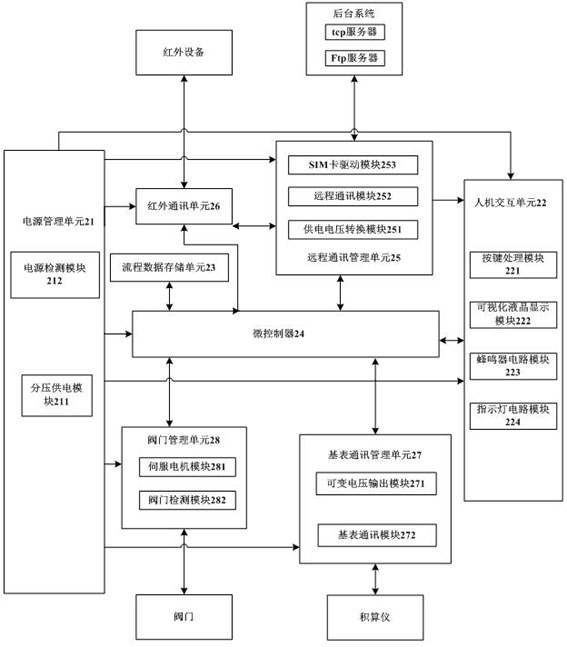

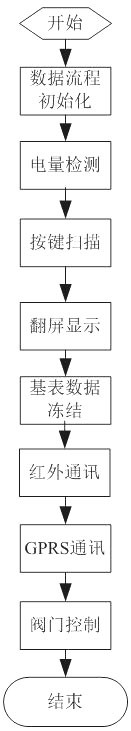

[0092] Example 1: Base table communication process

[0093] The base meter communication process includes two processes: base meter power-on and base meter communication. The power-on voltage of the base meter and the communication data flow of the base meter depend on the set voltage and protocol of the base meter. When the base meter communication process is triggered, the microcontroller 24 first acquires the voltage and protocol type required for communication from the process data storage unit 23 . The voltage and protocol category can be set via infrared or remotely, and the setting range must be within the range of all protocols stored in the process data storage unit 23 . At present, there are more than a dozen types of protocol content, and users can choose the corresponding protocol type according to the type of calculator in reality. Then the microcontroller 24 communicates with the base meter communication module according to the protocol category and voltage. F...

example 2

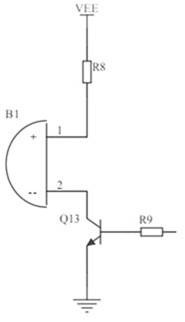

[0094] Example 2: Valve control process

[0095] The valve control process includes three items: valve opening, valve closing, and valve detection. When the valve is opened, the microcontroller 24 sends a power control signal to the servo motor module 281, the triode on-off circuit of the servo motor module 281 is turned on, and the voltage dividing power supply module 211 actually starts to power on the valve drive chip of the servo motor module 281. The controller 24 sends the valve opening control signal to the valve driver chip of the servo motor module 281 again, the valve driver chip is placed in the valve opening mode, the level of the valve opening line is set to high level, and the level of the valve closing line is set to low level. flat. Due to the direct electrical connection between the external valve and the valve chip, the external valve at this time will perform valve opening operation under voltage control. After the valve is opened for a period of time, the ...

example 3

[0096] Example 3: Remote communication process

[0097]The remote communication module 252 of the remote communication management unit 25 adopts a 4G full Netcom module, which is compatible with 2G, 3G, and 4G SIM cards of China Telecom, China Mobile, and China Unicom. The SIM card is installed on the SIM card driver module 253. The communication module 252 controls its driving and information exchange. The power supply voltage conversion module 251 is responsible for converting the power provided by the voltage dividing power supply module 211 into the voltage required by the remote communication module 252 . After the remote communication process is triggered internally or externally, the microcontroller 24 sends a control signal to the visual liquid crystal display module 222 to display the "signal mark" and start the countdown to report. The microcontroller 24 sends a control instruction to the power supply voltage conversion module 251 to make it truly communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com