A method for producing clean energy by using food waste

A food waste and clean energy technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of less biogas, inability to obtain hydrothermal charcoal, and low energy recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

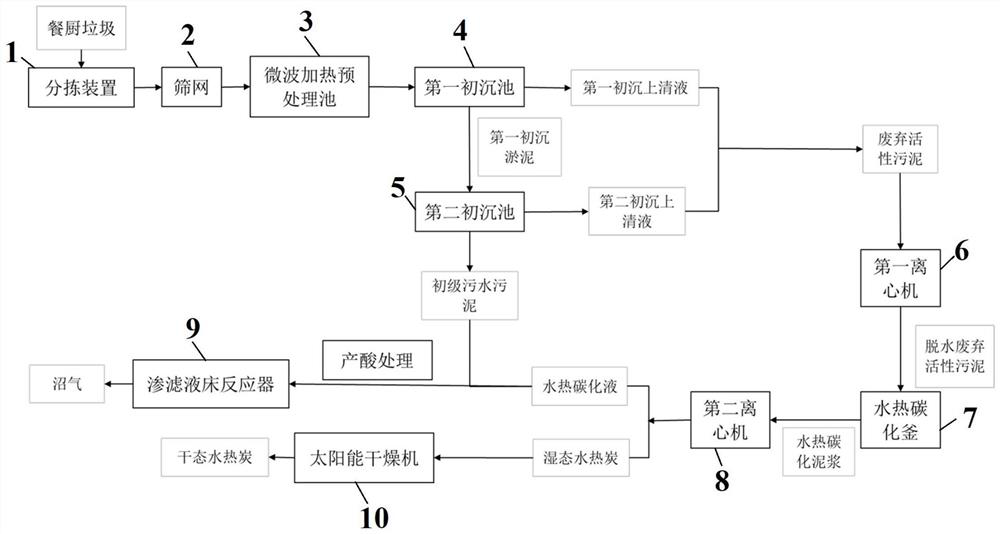

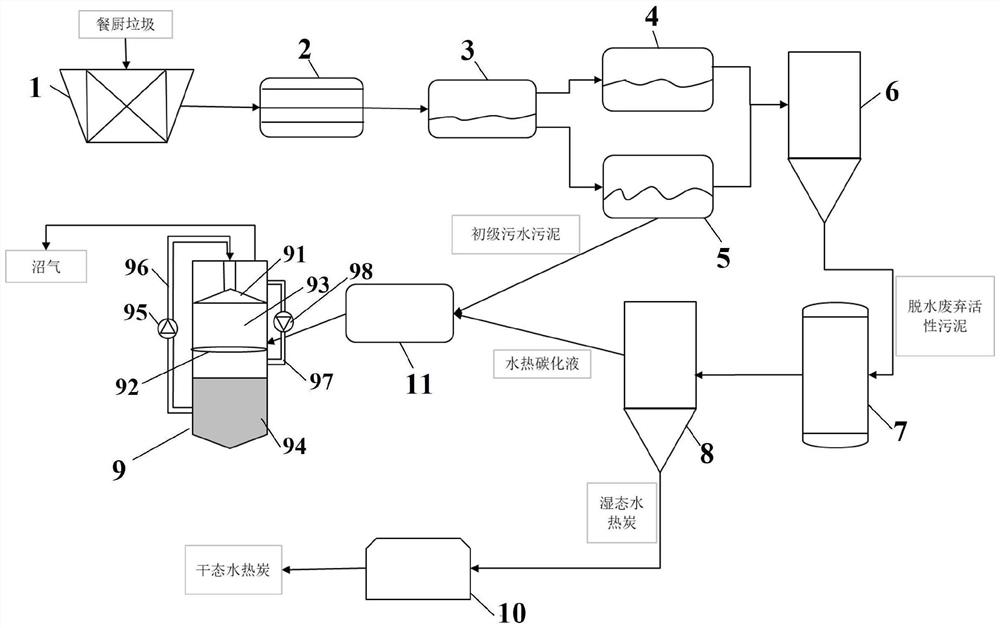

[0039] see Figure 1-2 , is a kind of method of utilizing food waste to produce clean energy of the present invention, comprises the following steps:

[0040] 1) Sorting the collected kitchen waste by using the sorting device 1 to sort the coarse solid waste, and using the screen 2 to screen out the silt and gravel;

[0041] 2) The mixture obtained in step 1) is transferred to the microwave heating pretreatment tank 3 for pretreatment;

[0042] 3) the pretreated mixture obtained in step 2) is transferred to the first primary sedimentation tank 4 for sedimentation;

[0043] 4) The first primary sedimentation sludge obtained after passing through the first primary sedimentation tank 4 in step 3) is transferred to the second primary sedimentation tank 5 for sedimentation, and the sludge obtained by the sedimentation is primary sewage sludge;

[0044] 5) mixing the first primary sedimentation supernatant obtained after step 3) passing through the first primary sedimentation tank...

Embodiment 2

[0054] see figure 1 , image 3 , a kind of method that utilizes food waste to produce clean energy provided by the present invention, comprises the following steps:

[0055] 1) Sorting the collected kitchen waste by using the sorting device 1 to sort the coarse solid waste, and using the sieve (2) to screen out the silt and gravel;

[0056] 2) The mixture obtained in step 1) is transferred to the microwave heating pretreatment tank 3 for pretreatment;

[0057] 3) the pretreated mixture obtained in step 2) is transferred to the first primary sedimentation tank 4 for sedimentation;

[0058] 4) The first primary sedimentation sludge obtained after passing through the first primary sedimentation tank 4 in step 3) is transferred to the second primary sedimentation tank 5 for sedimentation, and the sludge obtained by the sedimentation is primary sewage sludge;

[0059] 5) the first primary sedimentation supernatant obtained after the first primary sedimentation in step 3) through...

Embodiment 3

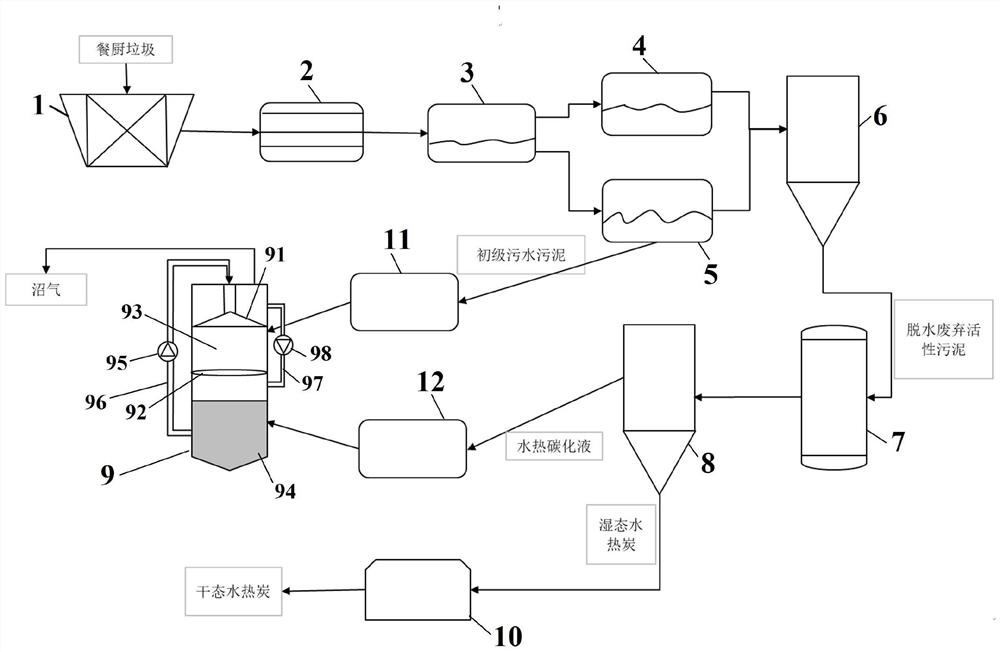

[0069] see figure 1 , image 3 , a kind of method that utilizes food waste to produce clean energy provided by the present invention, comprises the following steps:

[0070] 1) Sorting the collected kitchen waste by using the sorting device 1 to sort the coarse solid waste, and using the sieve (2) to screen out the silt and gravel;

[0071] 2) The mixture obtained in step 1) is transferred to the microwave heating pretreatment tank 3 for pretreatment;

[0072] 3) the pretreated mixture obtained in step 2) is transferred to the first primary sedimentation tank 4 for sedimentation;

[0073] 4) The first primary sedimentation sludge obtained after passing through the first primary sedimentation tank 4 in step 3) is transferred to the second primary sedimentation tank 5 for sedimentation, and the sludge obtained by the sedimentation is primary sewage sludge;

[0074] 5) the first primary sedimentation supernatant obtained after the first primary sedimentation in step 3) through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com