Self-cleaning polyethylene material and preparation method thereof

A polyethylene and self-cleaning technology, which is applied in the field of functional materials, can solve the problems of failure to consider the difference of parts and many processes, and achieve the effect of avoiding uncontrollable processing state, simple production process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

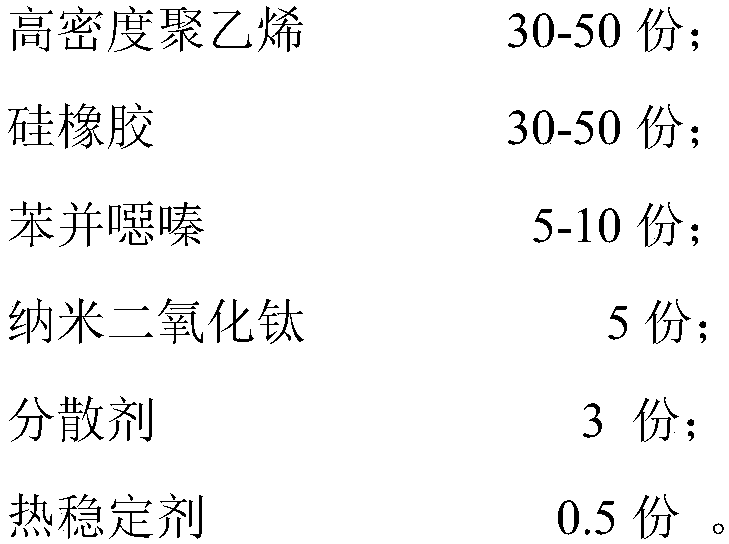

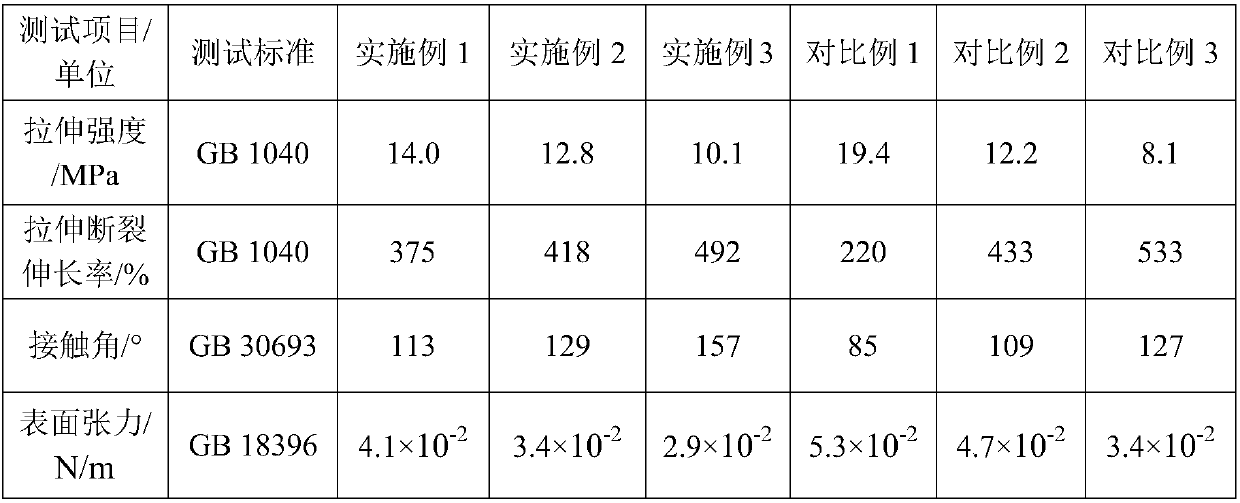

Embodiment 1

[0022] Add 50 parts of high-density polyethylene to the torque rheometer to melt smoothly, then add 30 parts of silicone rubber, 10 parts of benzoxazine, 5 parts of nano-titanium dioxide, 3 parts of dispersant, 0.5 parts of heat stabilizer, torque After the plate is stable, the material can be obtained from the film.

Embodiment 2

[0024] Add 40 parts of high-density polyethylene to the torque rheometer to melt smoothly, then add 40 parts of silicone rubber, 8 parts of benzoxazine, 5 parts of nano-titanium dioxide, 3 parts of dispersant, 0.5 parts of heat stabilizer, and torque After the plate is stable, the material can be obtained from the film.

Embodiment 3

[0026] Add 30 parts of high-density polyethylene to the torque rheometer to melt smoothly, then add 50 parts of silicone rubber, 5 parts of benzoxazine, 5 parts of nano-titanium dioxide, 3 parts of dispersant, 0.5 parts of heat stabilizer, torque After the plate is stable, the material can be obtained from the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com