Full-automatic vertical rack longitudinal polishing machine

A polishing machine, fully automatic technology, used in surface polishing machine tools, grinding/polishing equipment, automatic grinding control devices, etc., can solve problems such as inability to meet electric steering gear, achieve flexible setting of operating data, avoid The effect of stacking and saving beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

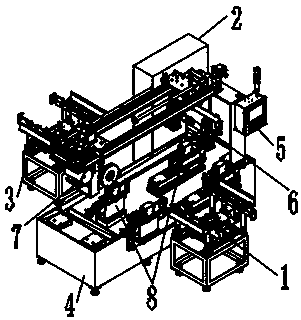

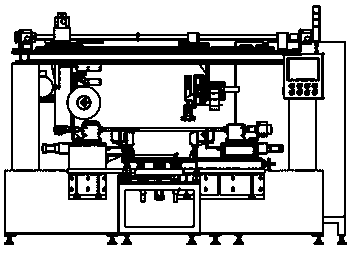

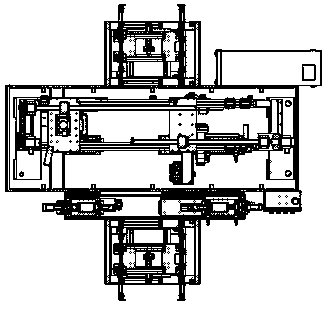

[0017] refer to figure 1 , figure 2 , image 3 As shown, the rack longitudinal polishing machine of the present invention is driven by an automatic feeding mechanism 1, a PLC electrical control box 2, an automatic unloading mechanism 3, a frame 4, a touch screen control panel 5, an automatic unloading mechanism 6, a polishing mechanism 7 and a top drive The organization consists of 8. The automatic feeding mechanism 1 is connected to the frame 4 through a bolt group; the PLC electrical control box 2 is connected to the touch screen control panel 5 through a data bus; the automatic unloading mechanism 3 is connected to the frame 4 through a bolt group; the top drive mechanism 8 is connected to the frame 4. Connected by bolt groups; the top drive mechanism 8 is respectively connected with the touch screen control panel 5 and the PLC electrical control box 2 through data lines;

[0018] refer to Figure 4 As shown, the preload servo motor 7-1 is connected with the preload se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com