A method for producing pure cobalt-manganese sulfate solution from zinc smelting cobalt slag

A technology for smelting cobalt manganese sulfate and zinc, applied in the direction of improving process efficiency, etc., can solve the problems of inability to maximize the benefit of valuable metals, complex composition of zinc smelting cobalt slag, low direct sales price, etc., and achieve significant economic benefits and Social benefits, reducing hazardous waste output, and increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

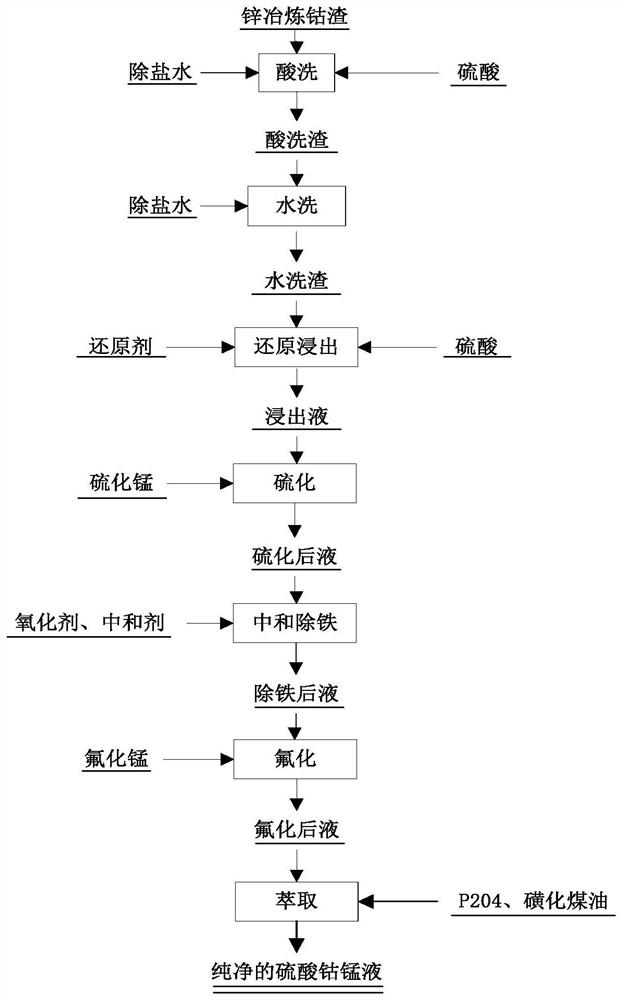

[0035] The method for producing pure cobalt-manganese sulfate solution from zinc smelting cobalt slag of the present invention, the detailed steps of this production method are as follows:

[0036] a. First, add demineralized water to the zinc smelting cobalt slag for slurrying according to the liquid-solid ratio of 3:1, add concentrated sulfuric acid according to the acidity of 70g / L, heat up to 85°C for pickling for 4 hours, and press filter to obtain the pickling slag;

[0037] b. Adding desalted water to slurry the pickling slag obtained in step a according to the liquid-solid ratio of 3:1, then washing with desalted water for 1 hour at room temperature, and pressing to obtain the washed slag;

[0038] c. Add desalted water to the washed slag obtained in step b according to a liquid-solid ratio of 3:1 for slurrying, then add concentrated sulfuric acid twice the theoretical amount, maintain the reaction temperature at 80°C, slowly add double hydrogen peroxide with a theoreti...

Embodiment 2

[0044] The method for producing pure cobalt-manganese sulfate solution from zinc smelting cobalt slag of the present invention, the detailed steps of this production method are as follows:

[0045] a. First, add demineralized water to the zinc smelting cobalt slag according to the liquid-solid ratio of 4:1 for slurrying, add concentrated sulfuric acid according to the acidity of 60g / L, heat up to 90°C for pickling for 3 hours, and press filter to obtain the pickling slag;

[0046] b. Adding desalted water to slurry the pickling slag obtained in step a according to the liquid-solid ratio of 4:1, then washing with desalted water at room temperature for 1 hour, and pressing to obtain the washed slag;

[0047] c. Add desalted water to the water-washed slag obtained in step b according to the liquid-solid ratio of 4:1 for slurrying, then add concentrated sulfuric acid with a theoretical dosage of 1.8 times, maintain the reaction temperature at 75°C, slowly add theoretical dosage of ...

Embodiment 3

[0053] The method for producing pure cobalt-manganese sulfate solution from zinc smelting cobalt slag of the present invention, the detailed steps of this production method are as follows:

[0054] a. First, add demineralized water to the zinc smelting cobalt slag according to the liquid-solid ratio of 5:1 for slurrying, add concentrated sulfuric acid according to the acidity of 50g / L, heat up to 90°C for pickling for 2 hours, and press filter to obtain the pickling slag;

[0055] b. Adding desalted water to slurry the pickling slag obtained in step a according to the liquid-solid ratio of 5:1, then washing with desalted water for 1 hour at normal temperature, and pressing to obtain the washed slag;

[0056] c. Add the water-washed slag obtained in step b to desalted water according to the liquid-solid ratio of 5:1 for slurrying, then add concentrated sulfuric acid with a theoretical dosage of 1.5 times, maintain the reaction temperature at 70°C, slowly add a theoretical dosage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com