Method for preparing reductive iron powder and high-purity refined iron powder by using iron ores

A technology for reducing iron powder and iron ore, applied in the field of mineral processing, can solve the problems of not wide application range, increased operation difficulty, long production cycle, etc., and achieve the effects of wide application range, stable product quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

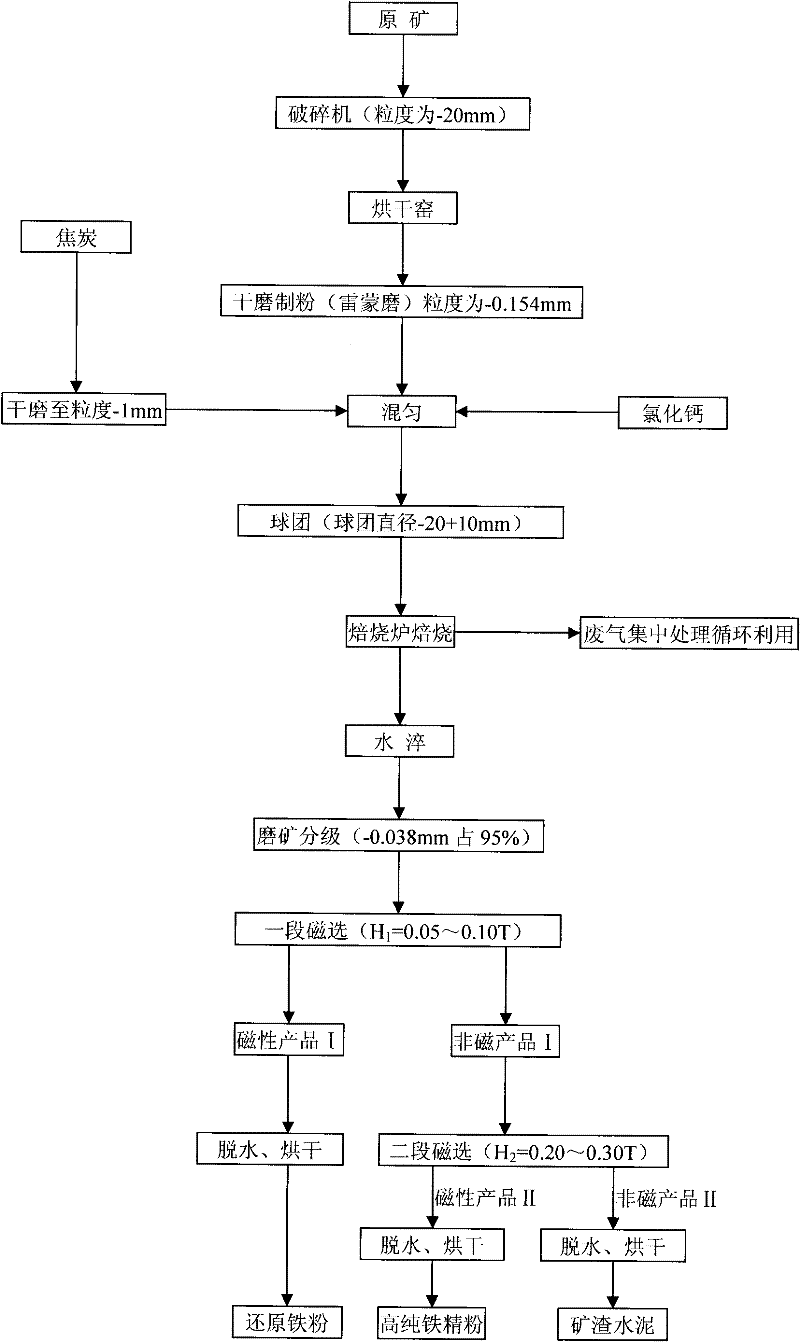

Method used

Image

Examples

Embodiment 1

[0032] The ore samples come from the Huimin area of Yunnan, and the iron content of the raw ore is 42-48%, which belongs to weathered fine-grained red limonite. Crush the ore until the particle size is less than 20mm, then put it into the drying equipment for drying, the drying temperature is 400°C, and the external moisture is controlled to be less than 5%; the dried sample is dry ground to -100 mesh powder by Raymond mill Like sample, add dry ore mass fraction 30% CaCl 2 , 15% coke (grain size -1mm), mix with the powder sample, use the pelletizer to pellet the mixed sample to -20+10mm pellets, put the pellets into the drying equipment , dried until the external moisture is less than 5%, the drying temperature is 400°C, the dried pellet sample is transported to the roaster for chlorination reduction roasting, the roasting temperature is 1000°C, the roasting time is 60min, and the grinding fineness is - 0.038mm accounts for 95%, and then carry out two stages of magnetic sep...

Embodiment 2

[0036] The ore sample comes from a certain area in Sichuan. The raw ore contains 32-43% iron. The ore composition is relatively complex, and the embedded particle size is quite fine. Crush the ore until the particle size is less than 20mm, then put it into the drying equipment for drying, the drying temperature is 400°C, and the external moisture is controlled to be less than 5%; the dried sample is dry ground to -100 mesh powder by Raymond mill Like sample, add 40% CaCl in mass fraction of dry ore 2 , 25% coke (grain size -1mm), mix with the powdery sample, use a pelletizer to pellet the mixed sample to -20+10mm pellets, put the pellets into the drying equipment , dried until the external moisture is less than 5%, the drying temperature is 400°C, the dried pellet sample is transported to the roaster for segregation roasting, the roasting temperature is 950°C, the roasting time is 90min, and the grinding fineness is -0.038mm Accounting for 95%, the magnetic field strength of ...

Embodiment 3

[0040]The ore samples come from a certain area in Guangxi, and the raw ore contains about 48-53% iron, which is a typical limonite ore. Crush the ore until the particle size is less than 20mm, then put it into the drying equipment for drying, the drying temperature is 400°C, and the external moisture is controlled to be less than 5%; the dried sample is dry ground to -100 mesh powder by Raymond mill Like sample, add 10% CaCl in mass fraction of dry ore 2 , 10% coke (grain size -1mm), mix with the powdery sample, use a pelletizer to pellet the mixed sample to -20+10mm pellets, put the pellets into the drying equipment , dried until the external moisture is less than 5%, the drying temperature is 400°C, the dried pellet samples are transported to the roaster for segregation roasting, the roasting temperature is 1100°C, the roasting time is 45min, and the grinding fineness is -0.038mm Accounting for 95%, the magnetic field strength of the first section of magnetic separation H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com