High-performance aqueous acrylic polyurethane bicomponent coating material

An acrylic polyurethane, two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor stability, fullness, weather resistance, poor water resistance, and single function of water-based paint, and achieve enhanced wear resistance. properties, film densification, and the effect of improving light resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

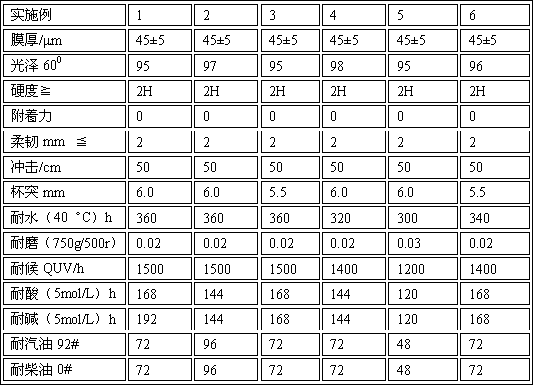

Examples

Embodiment 1

[0028] Embodiment 1: a kind of high-performance water-based acrylic polyurethane two-component coating, the mass ratio of main agent and water-based polyurethane curing agent is 5:1,

[0029] The composition and weight ratio of the main agent are (the total amount of the formula is based on 100g):

[0030] Polymer emulsion (DIC 570) 60g, silicone dispersion (MOBRID 511) 5g, conventional surface additives (TEGO 820760 4100) 2g, film-forming additives (DOW DPM DPNB) 5g, pigments and fillers (DUPONT706) 20g, ultraviolet light Absorbent (BASF1130) 1g, deionized water 20g, anti-sedimentation agent (AQ633E) 1g, thickener (RHEOLATE299) 1g;

[0031] The curing agent includes the following components by weight (the total amount of the formula is based on 100g):

[0032] Isocyanate curing agent (2655) 80 g, PMA (DOW) 20 g.

[0033] A kind of preparation method of high-performance waterborne acrylic polyurethane two-component paint, comprises the steps:

[0034] The first step: the pr...

Embodiment 2

[0042] Embodiment 2: a kind of high-performance water-based acrylic polyurethane two-component coating, the mass ratio of main agent and water-based polyurethane curing agent is 5:1,

[0043] The composition and mass ratio of the main agent are (the total amount of the formula is calculated as 100g)

[0044] Polymer emulsion (XK540) 60g, silicone dispersion (MOBRID 511) 5g, conventional surface additives (TEGO 820760 4100) 2g, film-forming additives (DOW DPM DPNB) 5g, pigments and fillers (DUPONT706) 20g,

[0045] UV absorber (BASF1130) 1g, deionized water 25g, anti-settling agent (AQ633E) 1g, thickener (RHEOLATE299) 1g.

[0046] The curing agent includes the following components by weight (the total amount of the formula is based on 100g):

[0047] Isocyanate curing agent (2655) 80 g, PMA (DOW) 20 g.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0049] Embodiment 3: a kind of high-performance water-based acrylic polyurethane two-component coating, the mass ratio of main agent and water-based polyurethane curing agent is 5:1,

[0050] The composition and mass ratio of the main agent are (the total amount of the formula is based on 100g):

[0051] Polymer emulsion (2470) 60g, silicone dispersion (MOBRID 511) 5g, conventional surface additive (TEGO 820760 4100) 2g, film-forming additive (DOW DPM DPNB) 5g, pigment and filler (DUPONT706) 20g, ultraviolet light absorption Agent (BASF1130) 1g, deionized water 30g, anti-settling agent (AQ633E) 2g, thickener (RHEOLATE299) 1g.

[0052] The curing agent includes the following components by weight (the total amount of the formula is based on 100g):

[0053] Isocyanate curing agent 80 g, PMA (DOW) 20.

[0054] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com