Solar photo-thermal conversion composite film and preparation method thereof

A composite film and photothermal conversion technology, which is applied to the composite film with solar photothermal conversion performance and the field of preparation thereof, can solve the problems of easy decomposition and complicated preparation, and achieve the effects of easy availability of raw materials, simple operation and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

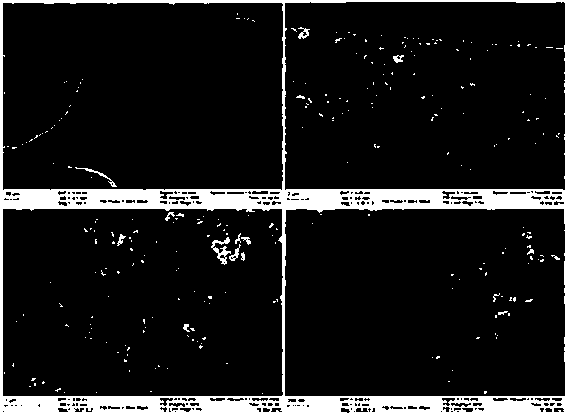

[0034] In this embodiment, the light-to-heat conversion composite film is based on a white cellulose film, copper acetate is used as a copper source, and thiourea is used as a sulfur source, and the empty shell is vulcanized through adsorption of copper ions, vulcanization, self-assembly and Ostwald ripening. Copper nanoparticles grown on cellulose.

[0035] In this example, the light-to-heat conversion composite film is prepared according to the following method:

[0036]First, put the white cellulose film into hot water at 50°C for cleaning, then wash it with ultrapure water and absolute ethanol three times in sequence, and dry it under vacuum at 30°C for 12 hours before use. Prepare a 0.1M copper sulfate solution, immerse the cellulose film in the copper sulfate solution, and vibrate on a shaker for 24 hours. After the reaction, the cellulose film was taken out from the copper sulfate solution, washed several times with ultrapure water and absolute ethanol, and dried at 30...

Embodiment 2

[0041] The preparation method of this embodiment is the same as that of Example 1, except that the black cellulose film containing bamboo charcoal is selected as the substrate.

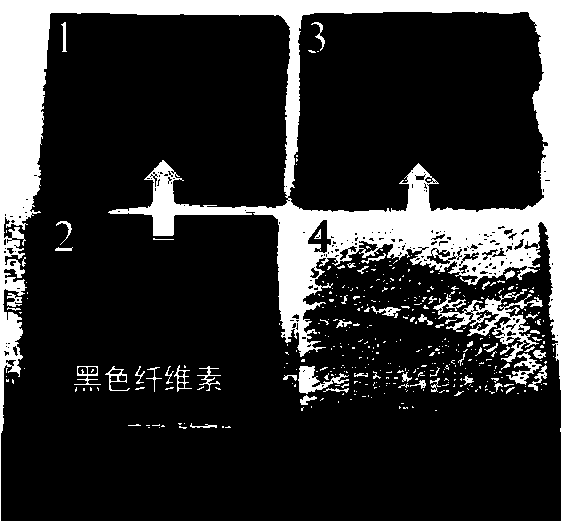

[0042] figure 1 The upper middle left (1) is an optical photo of a white cellulose-copper sulfide light-to-heat conversion composite film prepared on the basis of a black cellulose film. Figure 5 (4) is the thermogravimetric analysis diagram of the black cellulose-copper sulfide light-to-heat conversion composite film. It can be seen that the composite film has good thermal stability. Figure 6 Middle (1) is the time-temperature diagram of the black cellulose-copper sulfide light-to-heat conversion composite film under simulated solar irradiation, from Figure 6 can be obtained, at a power density of 1 kW m -2 Under the irradiation of simulated sunlight, the temperature of the black cellulose-copper sulfide composite film can be heated up to 70 °C.

Embodiment 3

[0044] The preparation method of this example is the same as that of Example 1, except that copper nitrate is used as the copper source and thioacetamide is used as the sulfur source to prepare a black cellulose-copper sulfide light-to-heat conversion composite film. The scanned picture is shown in Figure 7 Medium (1). After testing, the power density of the composite film is 1 kW m -2 Under the irradiation of simulated sunlight, the temperature can be warmed up to about 42 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com