Hydrothermal preparation method of bismuth selenide nano powder

A nano-powder, bismuth selenide technology, applied in nanotechnology, binary selenium/tellurium compounds, metal selenide/telluride and other directions, can solve the natural environment and human life hazards, the regulation and control limitations of powder morphology and size, etc. The problem is to achieve the effect of controllable morphology and size, low manufacturing cost, and simple and easy synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dissolve 1.8g NaOH in 80ml pure water, stir to dissolve, add 0.006mol SeO 2 , continue stirring to become a colorless transparent solution, then add 0.004mol Bi(NO 3 ) 3 ·5H 2 O, continue to stir for 10 minutes, the solution turns into a beige mixed solution, and finally add 0.0075 mol of gallic acid (GA) to the above mixed solution, and continue to stir for 15 minutes to fully mix.

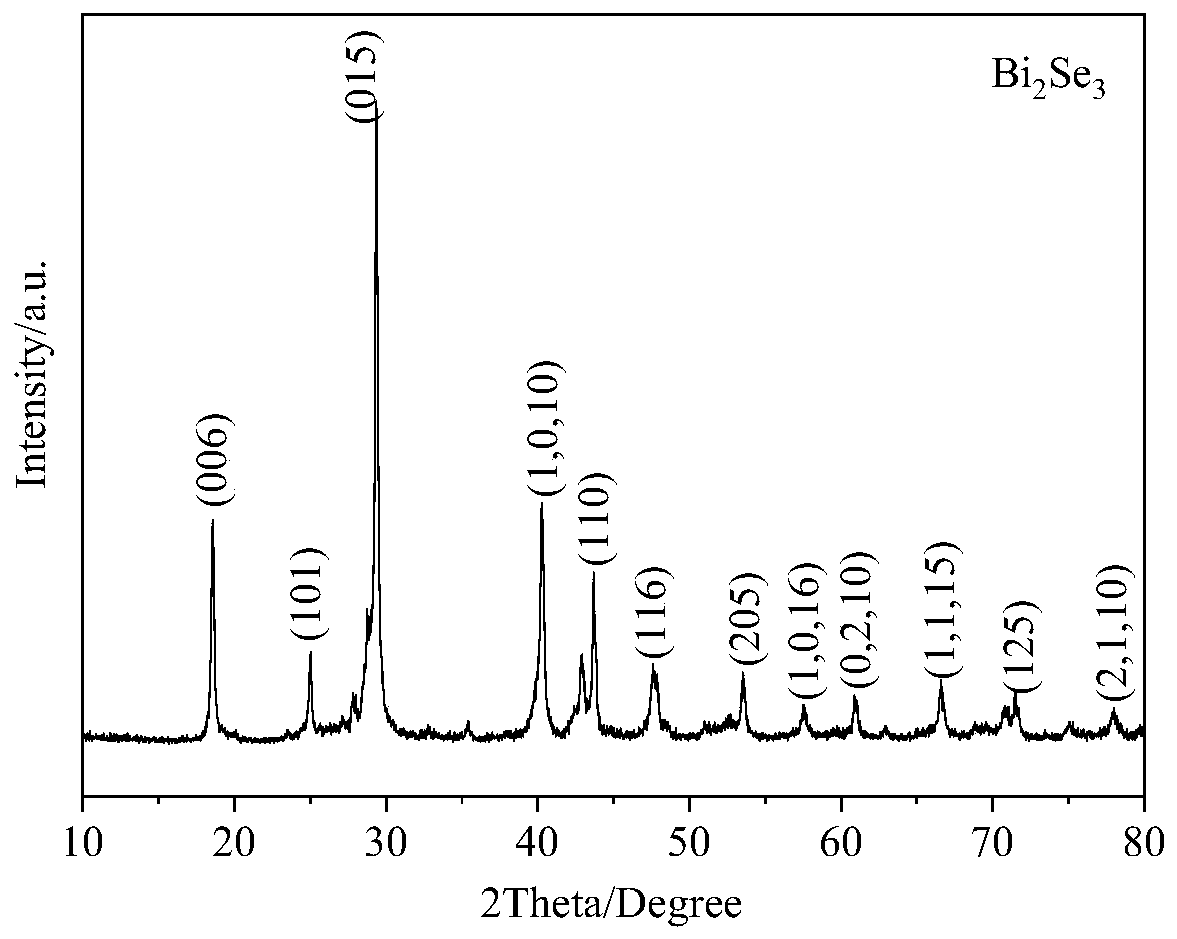

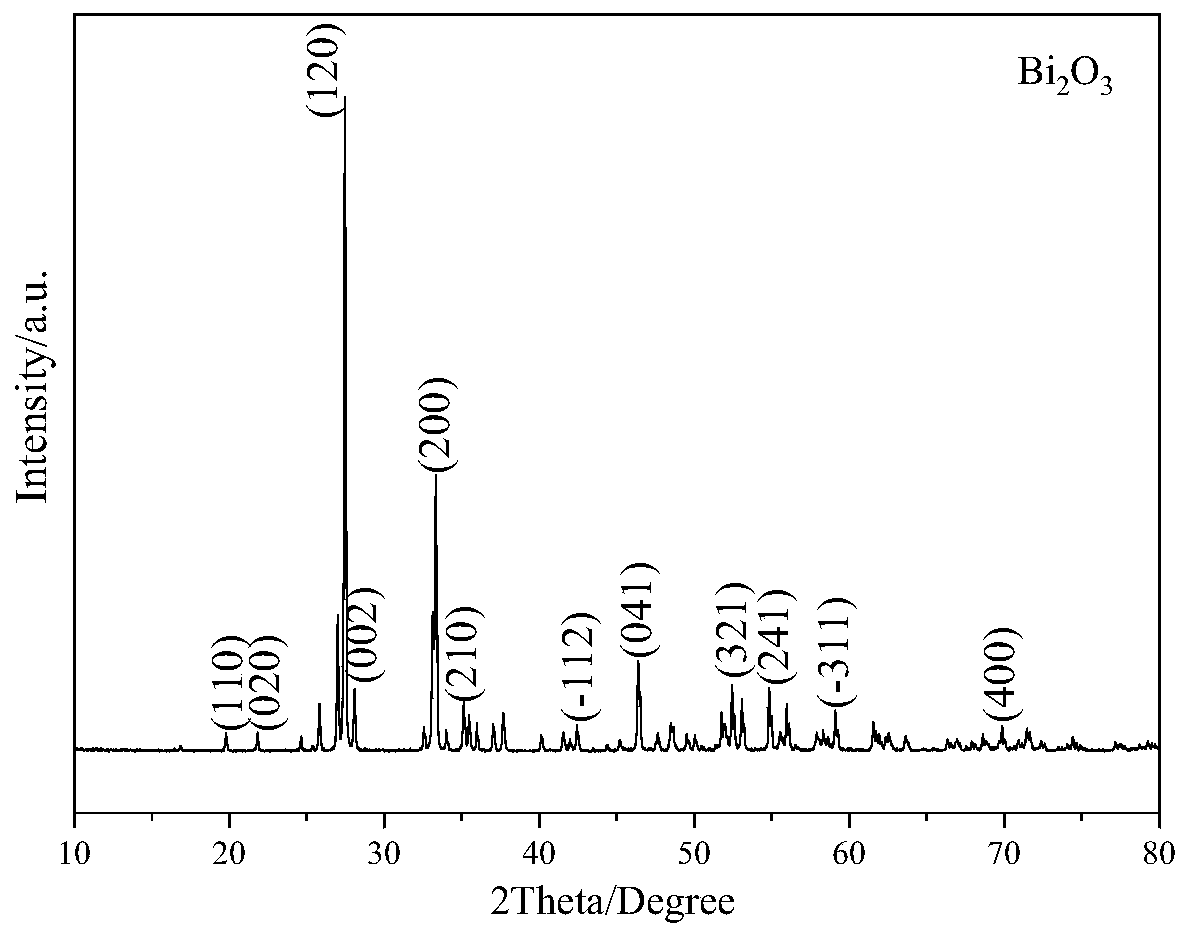

[0045] The above solution was transferred to a 100ml polytetrafluoroethylene reaction kettle, and the filling volume of the solution was 80%. It was placed in a preheated 200°C drying oven, reacted for 24 hours, and cooled naturally. Collect the black precipitate at the bottom of the hydrothermal reaction kettle and centrifuge at 4000rpm. The precipitate is washed three times with deionized water and once with absolute ethanol, and then dried in a vacuum oven at 60°C for 12 hours. , to obtain solid powder. X-ray diffraction (XRD) and scanning electron microscopy (SEM) were performed on...

Embodiment 2

[0050] Dissolve 2.1g NaOH in 80ml pure water, stir to dissolve and add 0.006mol SeO 2 , stirred to become a colorless transparent solution, and then added 0.004mol Bi(NO 3 ) 3 ·5H 2 O, continue to stir for 10min, the solution turns into a beige mixed solution, add 0.01mol gallic acid (GA) to the above mixed solution, finally add 0.2g surfactant Triton X-100, stir until the solution is evenly mixed.

[0051] The above solution was transferred to a 100ml polytetrafluoroethylene reaction kettle, placed in a preheated 150°C drying oven, and reacted for 12h. After natural cooling, collect the black precipitate at the bottom of the hydrothermal reaction kettle, centrifuge the black precipitate at 5000rpm, then wash the precipitate with deionized water for 3 times, and then wash with absolute ethanol for 2 times. After drying in a vacuum oven for 12 hours, a solid powder was obtained. Carry out X-ray diffraction (XRD) and scanning electron microscope (SEM) detection to solid powd...

Embodiment 3

[0053] Dissolve 2.0g NaOH in 80ml pure water, stir and dissolve to form a colorless and transparent solution. Then add 0.006mol SeO 2 and 0.004mol BiCl 3 , stirred for 10 minutes, the solution turned into a beige mixed solution, added 0.01mol gallic acid (GA) to the above mixed solution, continued to stir for 15 minutes, then added 0.625g Triton X-100, and continued to stir until the solution was evenly mixed.

[0054] The above solution was transferred to a 100ml polytetrafluoroethylene reaction kettle, and heated in a dry oven preheated to 250°C for 24h. After cooling, collect the black precipitate at the bottom of the hydrothermal reaction kettle, centrifuge at 5000rpm to separate the solid, then wash with deionized water for 3 times and absolute ethanol for 2 times, and finally dry it in a vacuum oven at 60°C for 12 hours to obtain a solid powder product. X-ray diffraction (XRD) and scanning electron microscope (SEM) detection are carried out to it, and the XRD pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com