Manufacturing method of medical bionic trabeculae structure multihole tantalum bone implant prosthesis through laser additive manufacturing-high-temperature vacuum sintering

A high-temperature vacuum and laser additive technology, which is applied to bone implants, prostheses, manufacturing tools, etc., can solve the problems of rising costs, increased oxygen content of tantalum metal products, and high tantalum oxygen content of 3D printed metals. Oxygen content requirements, pollution avoidance, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

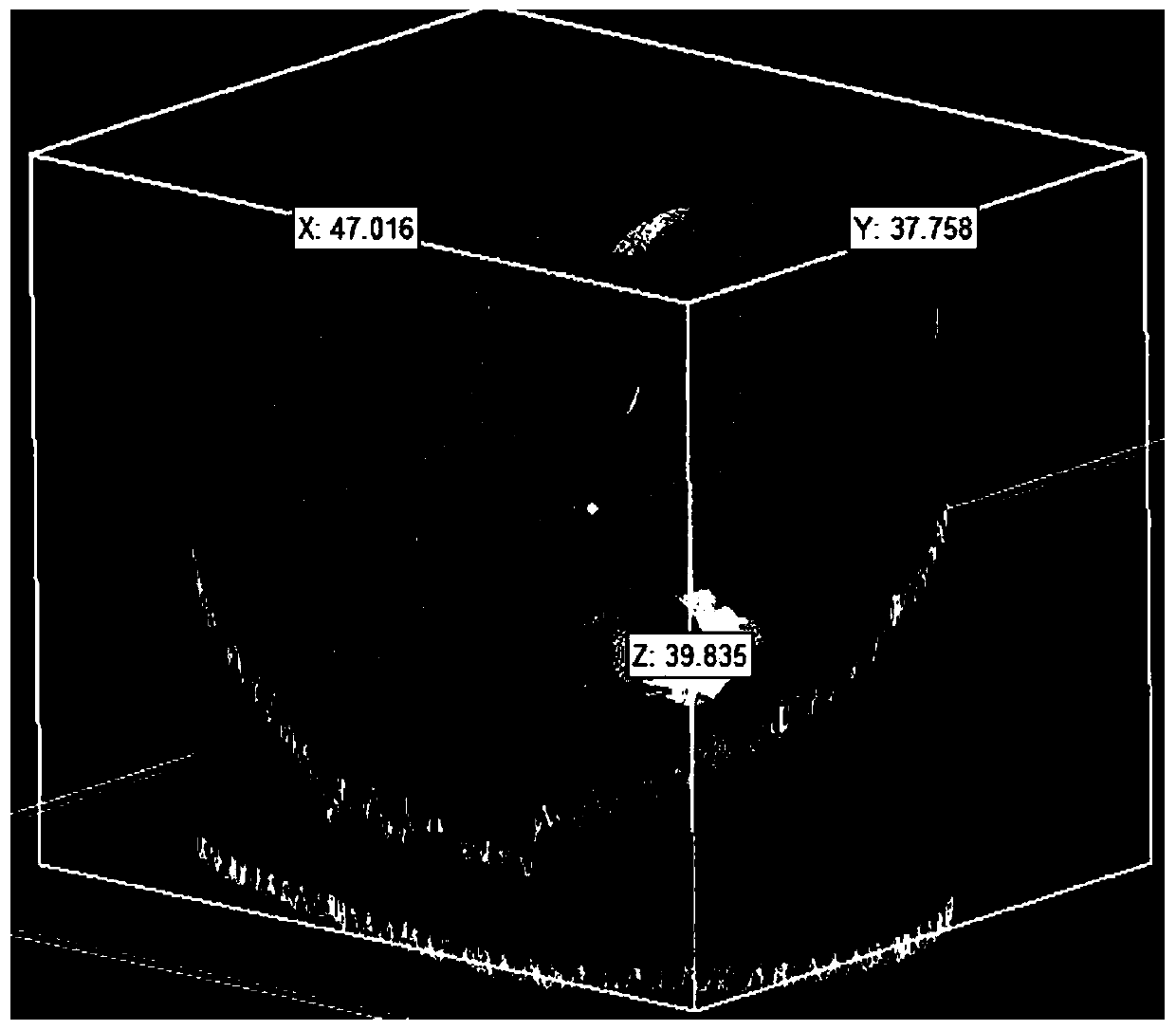

[0057] This embodiment provides a laser additive manufacturing-high temperature vacuum sintering method for manufacturing a porous tantalum knee joint patella prosthesis with a bone-like trabecular structure, such as figure 1 As shown, it is the three-dimensional design drawing of the implanted prosthesis and its support in this embodiment, such as figure 2 As shown, it is the printed physical map after the support is removed in this embodiment.

[0058] The batch number of tantalum powder used for 3D printing in this embodiment is 181221-270, particle size distribution: D50=29.38um, D10=10.56um, D90=58.99um; fluidity: 50g / 13.7 seconds; oxygen content 1138ppm; the tantalum The particle type of powder is hydrogenated polyhedral tantalum powder;

[0059] The oxygen content of the laser 3D printed porous tantalum knee joint patella prosthesis with bone-like trabecular structure was 1253ppm before high-temperature vacuum sintering and oxygen reduction treatment.

[0060] This e...

Embodiment 2

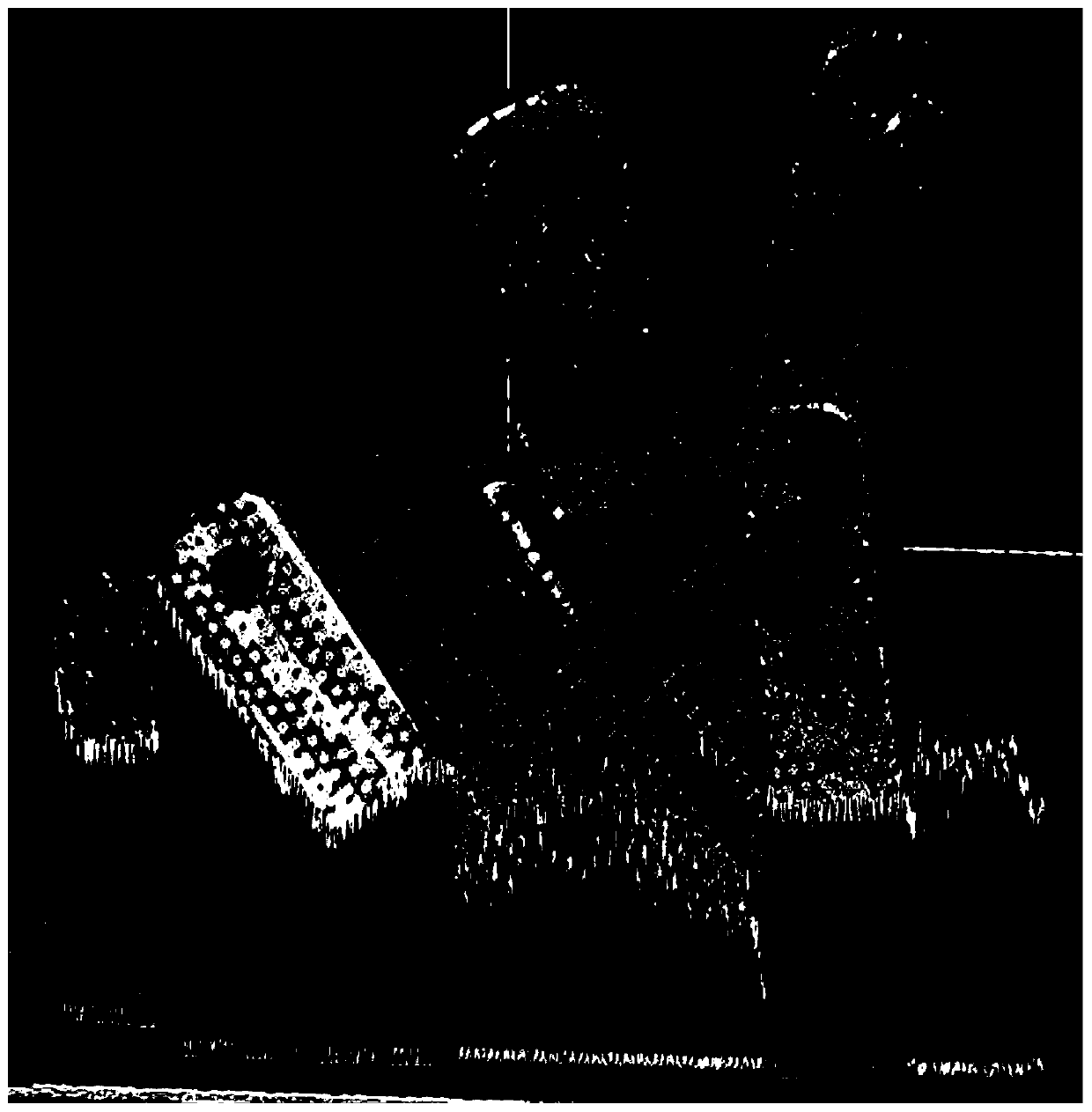

[0085] This embodiment provides a laser additive manufacturing-high temperature vacuum sintering method for manufacturing a prosthesis for bone reconstruction and repair after resection of a medical trabecular bone imitation porous tantalum pelvic tumor, such as image 3 As shown, it is the three-dimensional design drawing of the implanted prosthesis and its support in this embodiment, such as Figure 4 As shown, it is the simulated installation effect diagram (left) and the implantation effect X-ray photo (right) of the prosthetic prosthesis in this embodiment.

[0086] In this example, the porous tantalum with bone-like trabecular structure printed by laser 3D in this example is used for bone reconstruction and repair prosthesis after resection of pelvic tumors. The content is 1450ppm.

[0087] This embodiment specifically includes the following steps:

[0088] S1. Design of porous tantalum trabecular bone implant prosthesis: establish a 3D model of porous tantalum trabecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com