Quick-response all-solid-state electrochromic device and preparation method thereof

An electrochromic device, a fast-response technology, used in instruments, nonlinear optics, optics, etc., can solve the problems of low preparation efficiency and slow response speed of electrochromic devices, achieve excellent performance, reduce internal impedance, and improve preparation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

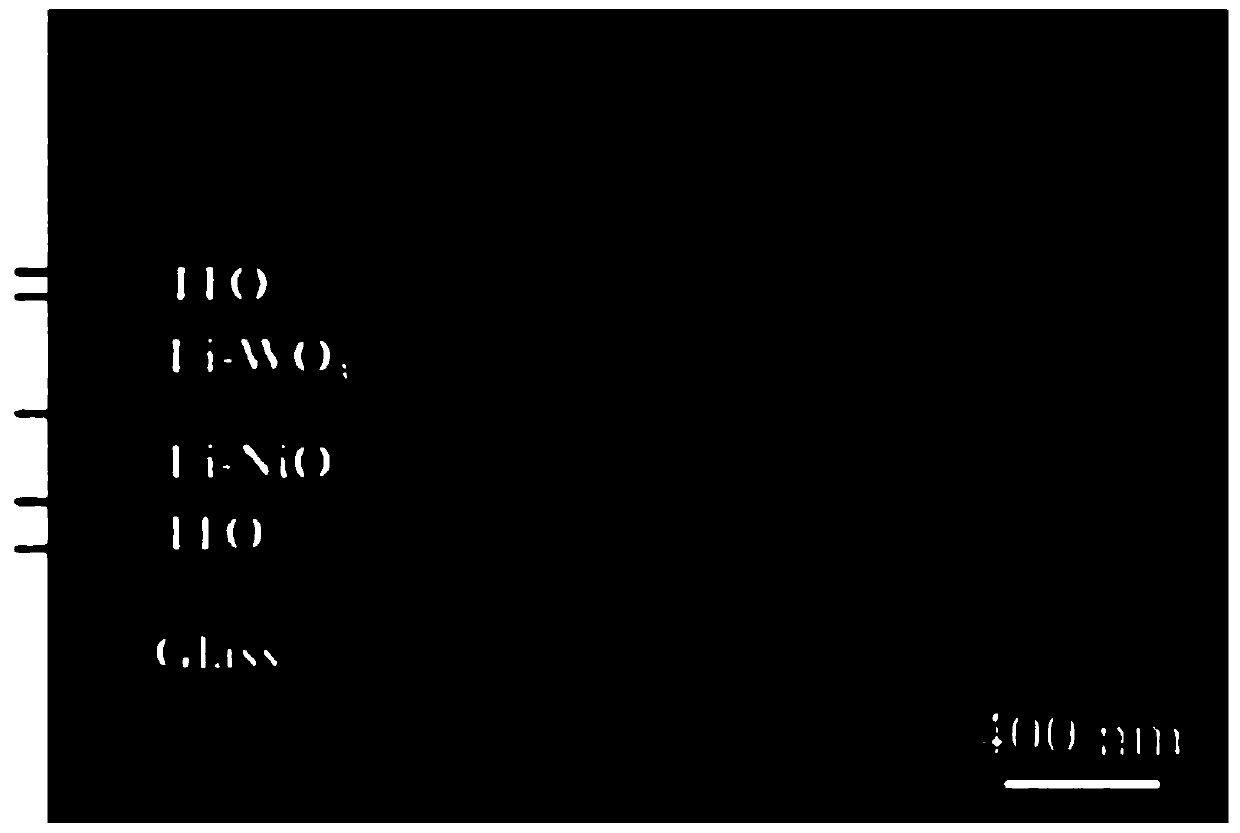

[0019] Embodiment 1: This embodiment is a fast-response all-solid-state electrochromic device consisting of a substrate, a bottom electrode layer, an electrochromic layer, a complementary color-changing layer, a lithium layer, and a top electrode layer; Bottom electrode layer, electrochromic layer, complementary color-changing layer and top electrode layer on the top or bottom electrode layer, complementary color-changing layer, electrochromic layer and top electrode layer on the substrate; The layers are distributed in the electrochromic layer and the complementary chromic layer.

specific Embodiment approach 2

[0020] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the substrate is a heat-resistant substrate or a flexible substrate; the heat-resistant substrate is glass; the flexible substrate is polyethylene terephthalate Glycol ester or Dimethicone. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the bottom electrode layer is an indium tin oxide layer, a fluorine-doped tin oxide layer or a metal layer; the metal is silver, gold or platinum. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com