Exhaust System Mufflers for Automobiles

A technology of exhaust system and muffler, which is applied in the field of auto parts and can solve the problem of weak muffler effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

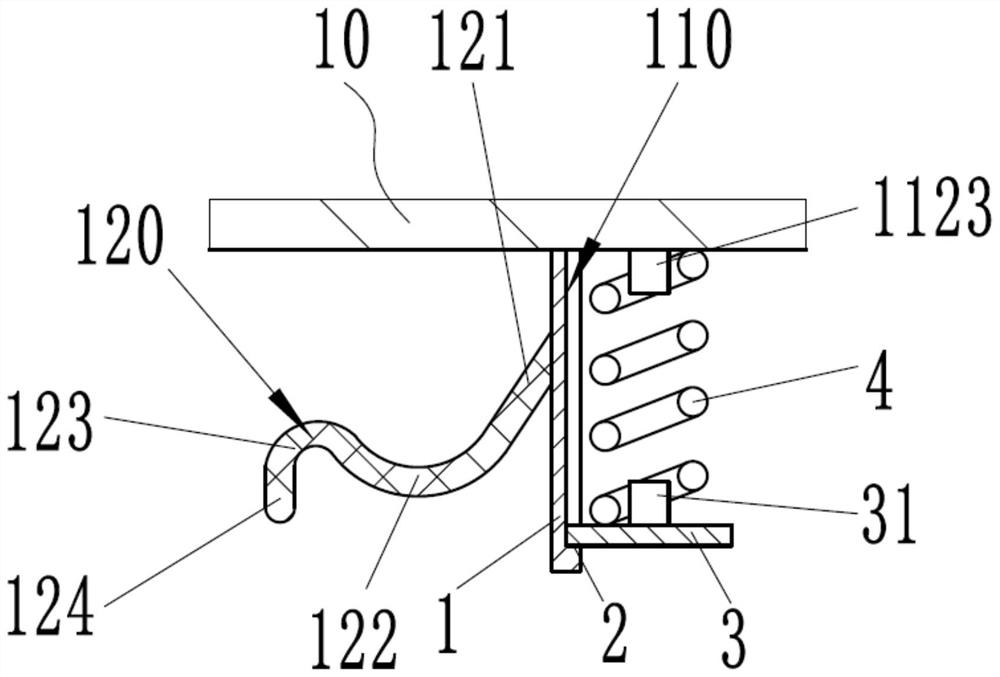

[0024] Such as figure 1 A kind of automobile exhaust system muffler shown is the main muffler of the exhaust system, comprising a shell 10, a partition 40 and an inner muffler pipe 50, the shell 10 has an inner cavity 11, and the inner cavity 11 One end communicates with the middle pipe 20 of the exhaust system, the other end of the inner chamber 11 communicates with the tailpipe 30 of the exhaust system, the partition 40 is arranged in the inner chamber 11, and the partition 40 A through hole 41 is opened on it, and the partition 40 divides the inner chamber 11 into a front chamber 111 and a rear chamber 112, the front chamber 111 communicates with the middle pipe 20, and the rear chamber 112 communicates with the tailpipe 30, the inner muffler pipe 50 is set in the rear chamber 112 through an annular plate 60, and the annular plate 60 divides the rear chamber 112 into a first rear chamber 1121 and the second rear chamber 1122, one end of the inner muffler pipe 50 extends in...

Embodiment 2

[0028] Such as figure 1 As shown, on the basis of the first embodiment, the side wall of the second conical tube 54 is provided with several vent holes 541, and the apertures of the vent holes 541 are all less than 1mm. When the gas flows through the second When the conical tube 54 is used, the energy loss of the sound wave due to gas flow in the propagation process depends on the friction loss of the air in the micropores, and the friction loss depends on the acoustic resistance of the second conical tube 54. The greater the acoustic resistance, the greater the frictional loss. The greater the loss, the acoustic resistance is inversely proportional to the square of the aperture. When the aperture is less than 1 mm, the acoustic resistance is greatly increased compared with the general perforated tube (the aperture is between several millimeters and tens of millimeters), thus making the second The sound absorption performance of the tapered pipe 54 is enhanced.

Embodiment 3

[0030] Such as figure 1 and figure 2 As shown, on the basis of the second embodiment, the side wall of the through hole 41 is provided with several cylinders 70 in a ring, and the adjacent cylinders 70 are connected by a short plate 80, and the short plate 80 is A rectangular hole 81 is opened, and a first channel 90 is formed between adjacent cylinders 70 and corresponding short plates 80 and the side walls of the through holes 41 , and between several cylinders 70 and several short plates 80 The second channel 100, when the gas flows from the second channel 100, the inner cavities of several cylinders 70, several first channels 90, and several rectangular holes 81 to the first rear chamber 1121, in the second channel 100 The confluence with the first rear chamber 1121, the confluence of the inner cavity of the cylinder body 70 and the first rear chamber 1121, the confluence of the first channel 90 and the first rear chamber 1121, the rectangular hole 81 and the first rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com