Jacking pipe rescue equipment for coal mine collapse roadway and jacking pipe rescue method for coal mine collapse roadway

A pipe jacking and roadway technology, applied in mining equipment, shaft equipment, tunnels, etc., can solve the problems of poor slag discharge efficiency and achieve high slag discharge efficiency and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

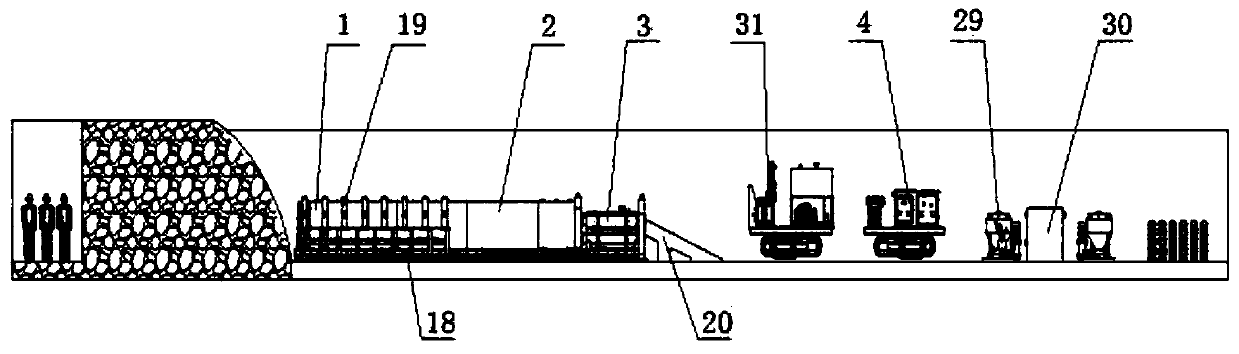

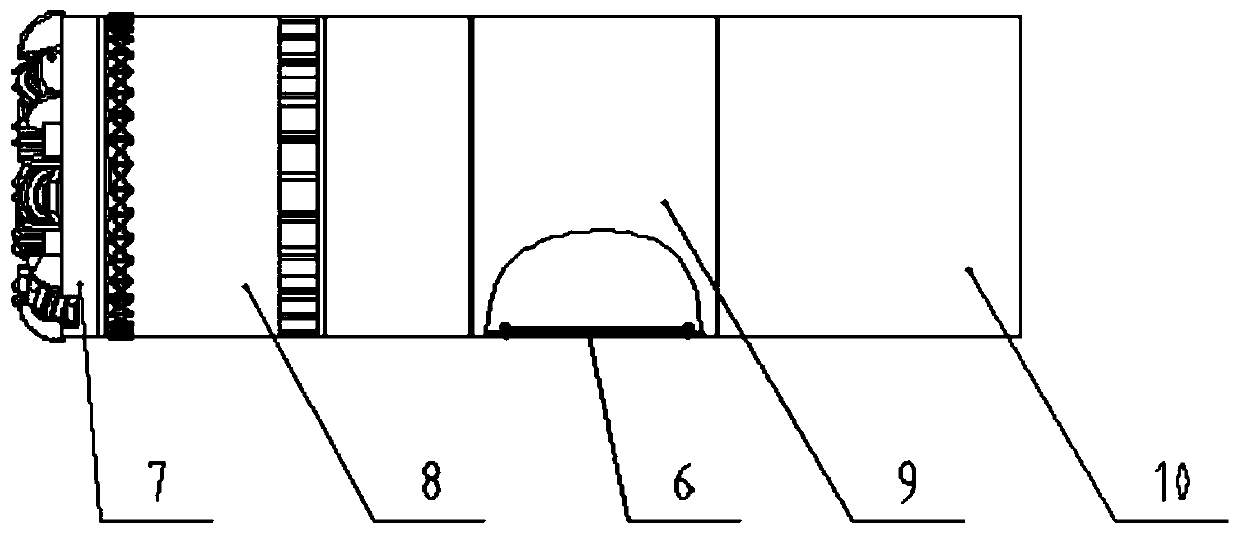

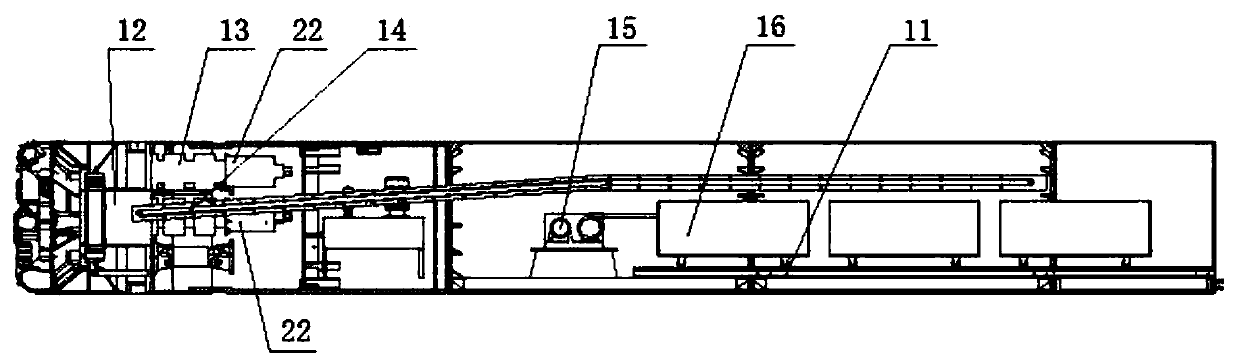

[0035] Such as Figure 1-Figure 5 As shown, the present embodiment proposes a rescue equipment for pipe jacking 2 in collapsing coal mine tunnels, including a body 1, several pipe jacking 2, a main jacking mechanism 3, a main jacking mechanism track 18 and a material delivery track 21, wherein the body 1 and the jacking The pipe 2 is movably installed on the rail 18 of the main jacking mechanism. The body 1 includes a cutter head 7 arranged at the front end of the body 1 and a driving device for driving the cutter head 7 to rotate. , the head end of the jacking pipe 2 group abuts against the tail end of the body 1, and the main jacking power end of the main jacking mechanism 3 abuts against the tail end of the jacking pipe 2 group, so as to push the body 1 along the main jacking mechanism through the jacking pipe 2 Track 18 moves forward;

[0036] The ground inside the jacking pipe 2 is provided with a slag truck track 11, and the two ends of the slag truck rail 11 are respec...

Embodiment 2

[0046] This embodiment proposes a pipe jacking 2 rescue method for a coal mine collapsed roadway, using the pipe jacking 2 rescue equipment for a coal mine collapsed roadway in Example 1, including

[0047] Arrangement: After a collapse accident occurs in the mine roadway, the main roof mechanism 3 is quickly transported to the site of the mine collapse accident, the main roof mechanism track 18 is arranged along the direction of the collapsed roadway, and the body 1 is placed on the main roof mechanism track 18. Carry out jacking in the direction of the track, place electric control equipment 4 and grouting equipment at the rear end of the main jacking equipment, and after the jacking pipe 2 rescue equipment is transported in place, arrange the pipe jacking 2 delivery track 21 on the side of the main jacking mechanism 3, and the pipe jacking 2 and the slag truck 16 is transported through the material delivery track 21;

[0048] After the arrangement is completed, jacking and ...

Embodiment 3

[0051] Generally speaking, the rescue equipment for pipe jacking 2 is composed of main jacking mechanism 3, electronic control equipment 4, pipe jacking 2, machine body 1 and grouting equipment. The whole set of equipment is arranged along the direction of the collapsed roadway. On the front side, the body 11 is placed on the upper end of the track 18 of the main top mechanism. The main top mechanism 3 realizes the positioning of the direction of the machine head through the tube clamp 19. The main top mechanism 3 adopts a self-supporting rear outrigger device 20. The material delivery track 21 is arranged on the material delivery track 21, and the transport vehicle 17 is arranged on the material delivery track 21, which is used for the transportation tool pipe and the slag transport vehicle 16. The electric control equipment 4, the grouting pump 5, and two mud mixers 29 are arranged on the rear side of the main jacking device and grouting tank.

[0052] Considering the limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com