Preparation method of COL/PEG@CaP biomineralization multilayer film

A biomineralization, multi-layer film technology, applied in coating, medical science, prosthesis and other directions, can solve problems such as hindering the development of nanomaterials, and achieve the effect of avoiding immune rejection, promoting cell directional differentiation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

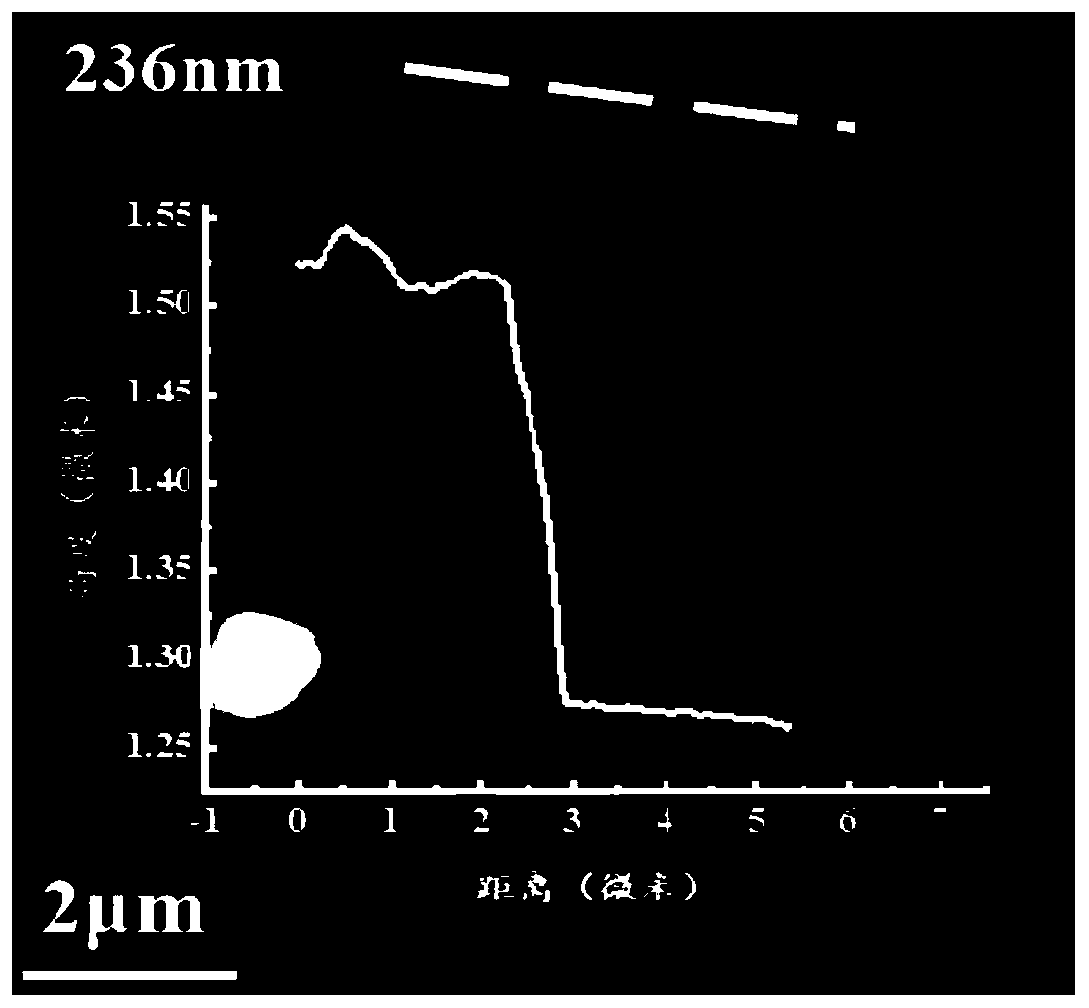

[0052] The embodiment of the present invention provides a method for preparing a COL / PEG@CaP biomineralized multilayer film, comprising the following steps:

[0053] (1) Using medical titanium alloy as the substrate, the titanium alloy substrate is subjected to plasma treatment to make its surface hydroxylated, so as to achieve better hydrophilicity, so as to facilitate the subsequent assembly process;

[0054] (2) Prepare 1 mg / mL DA solution and adjust its pH value to 8.5 with Tris solution, and magnetically stir to make DA polymerize to form a PDA solution.

[0055] (3) Soak the titanium alloy substrate in the PDA solution for 30 minutes to improve the adhesion of the surface of the substrate and make the substrate for subsequent polyelectrolyte assembly

[0056] (4) Prepare 1mg / mL COL solution, 1mg / mL PEG solution, 500mM CaCl respectively 2 solution and 300mM K 2 HPO 4 solution, and the pH value of the COL solution was adjusted to 3.5 with sodium hydroxide;

[0057] (5)...

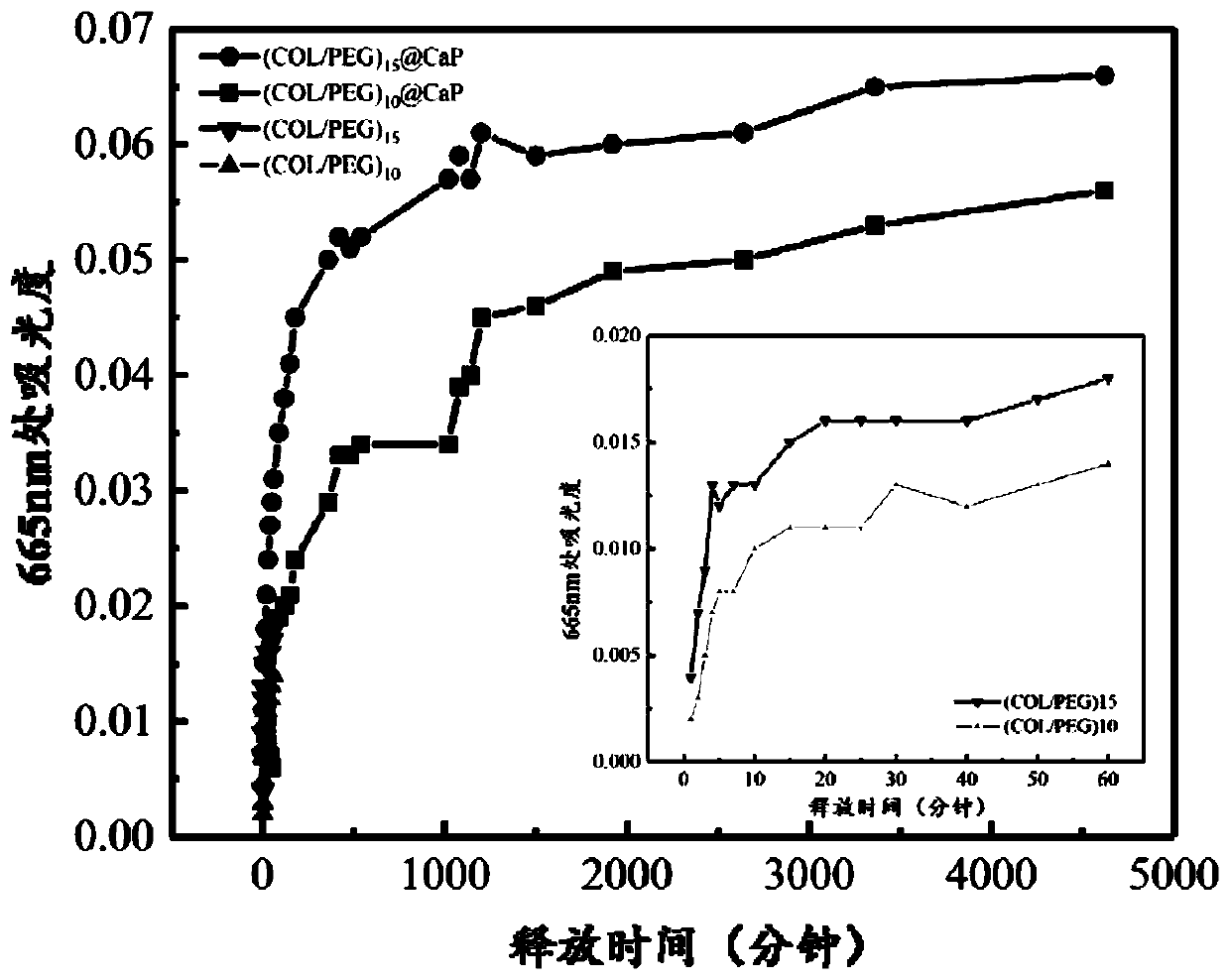

Embodiment 2

[0067] On the basis of Example 1, the difference between this Example and Example 1 is that in Step 7), Step 5) and Step 6) are alternately repeated 10 times; other parts are completely consistent with Example 1.

Embodiment 3

[0069] On the basis of Example 1, the difference from Example 1 in this example is that in step 4), the concentrations of the configured COL solution and PEG solution are both 0.5 mg / mL, and the pH of the COL solution is adjusted to 0.5 mg / mL with sodium hydroxide. The value is adjusted to 3.5; other parts are completely consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com