Demetallization recovery method of spent catalytic cracking catalyst

A catalytic cracking and demetallization technology, applied in the direction of catalytic cracking, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problems of complex process, limited application, high cost of resurrection, etc., and achieve short resurrection time, which is beneficial to industry The effect of production and improvement of resurrection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7、 comparative example 1

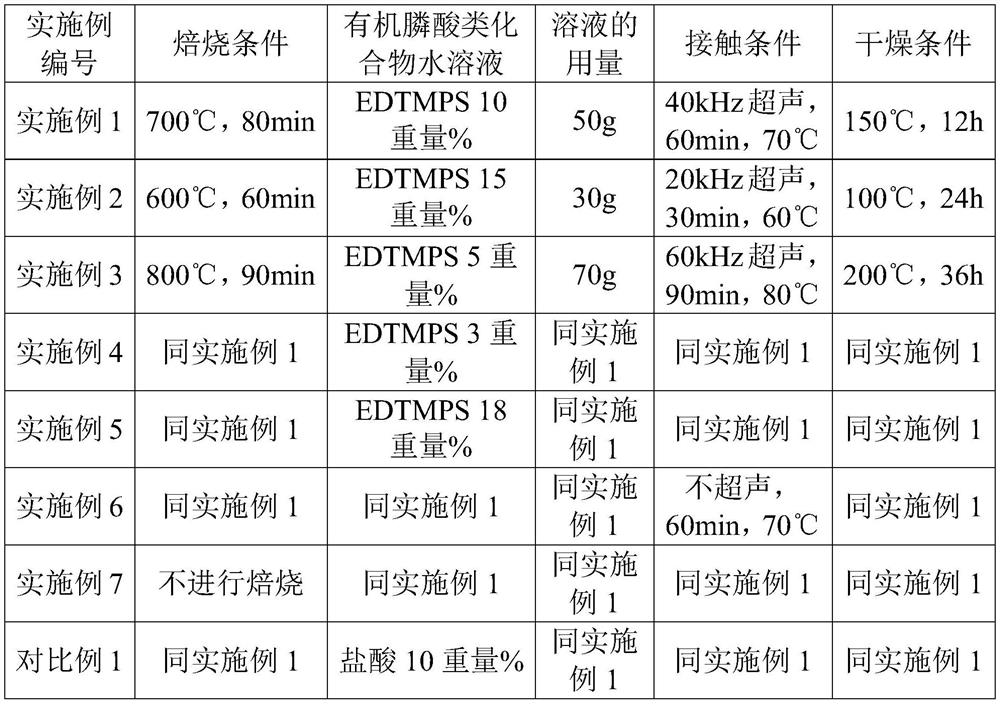

[0041] (1) 10g spent catalytic cracking catalyst is put into crucible, and is roasted in microwave muffle furnace according to the condition shown in table 1;

[0042] (2) putting the product of step (1) into a container, adding the aqueous solution of the organic phosphonic acid compound under stirring conditions according to the conditions shown in Table 1 to carry out contact treatment;

[0043] (3) the product of step (2) is cooled to room temperature, suction filtered, washed with deionized water to neutrality (pH=7), and dried in a blast drying oven according to the conditions shown in Table 1, to obtain revival catalytic cracking catalyst.

[0044] (4) The Ni removal rate, the V removal rate and the micro-reactive activity of the revived catalytic cracking catalyst were measured respectively, and the results are shown in Table 2.

[0045] Table 1

[0046]

[0047] Table 2

[0048] Example number Ni removal rate (%) V removal rate (%) Micro-reactive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com