Experimental method for simulating shale organic pore evolution process

A technology of organic pores and evolution process, applied in suspension and porous material analysis, measurement devices, instruments, etc., can solve problems such as restricting the formation and evolution of shale, avoid the influence of reasonable analysis of observation results, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

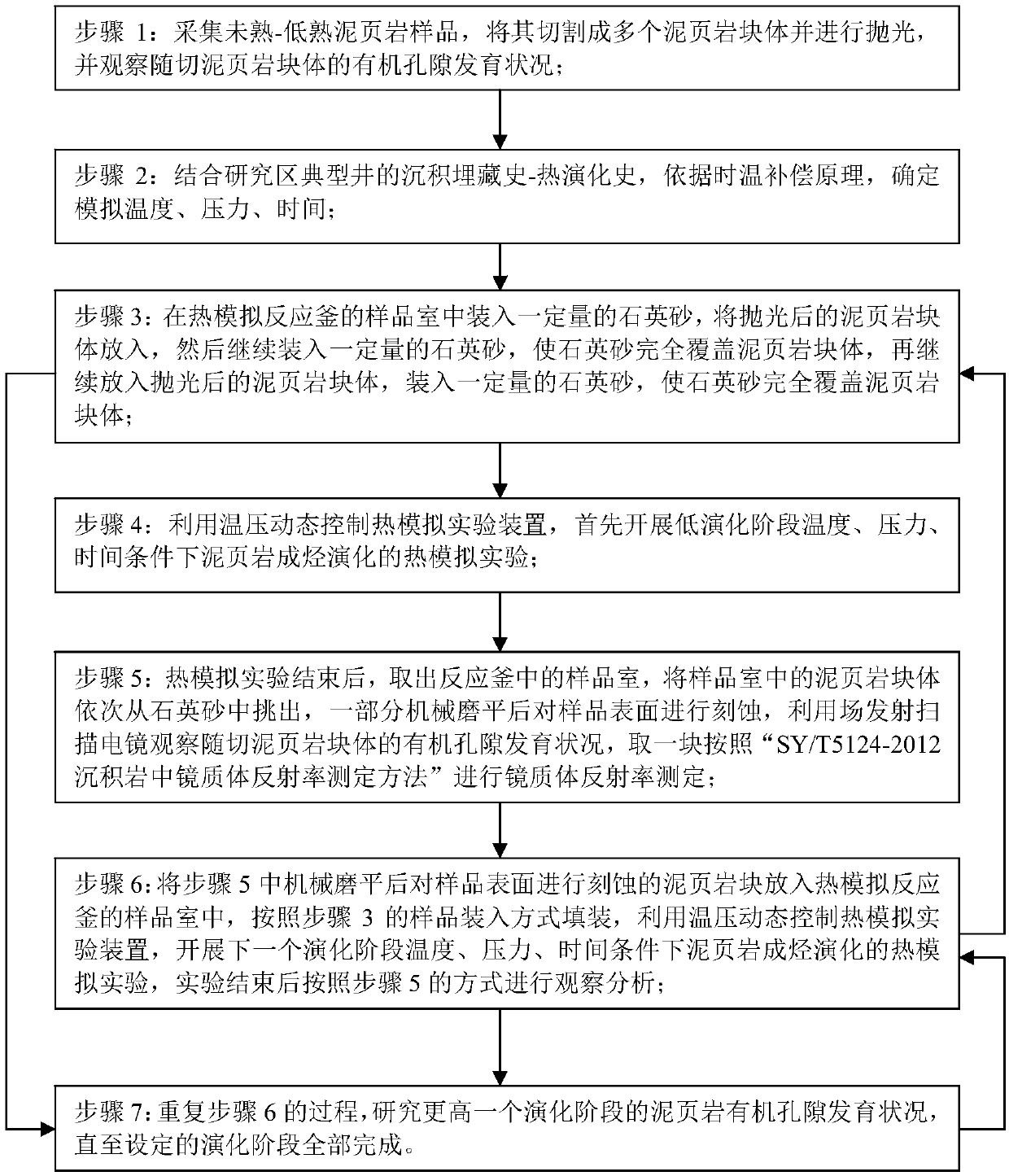

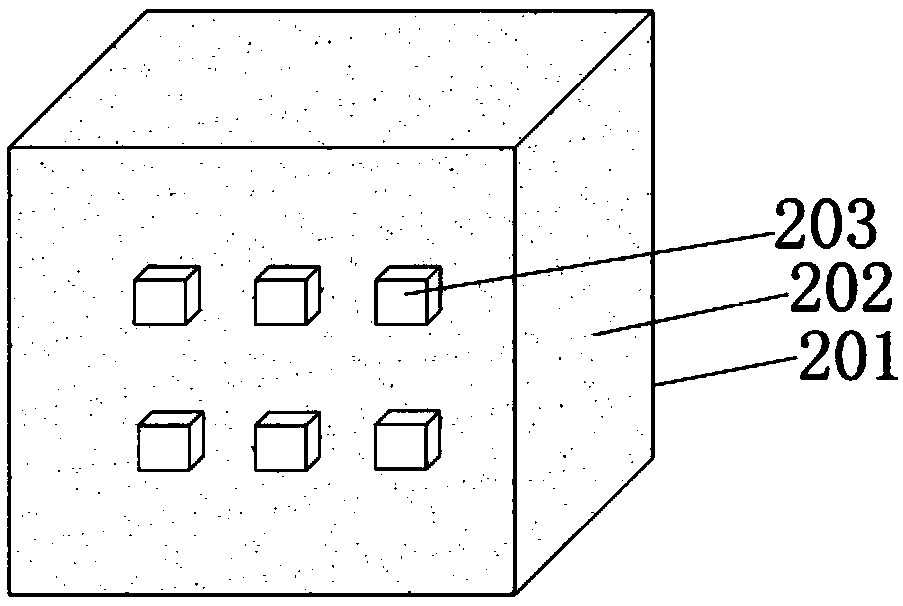

[0043] In the embodiment of the present invention, an experimental method for simulating the evolution process of organic pores in shale is provided, such as figure 1 As shown, the method includes:

[0044] Step 1: Select the immature marine shale of the Upper Cretaceous Colorado Group 2WS (Second White Specks Formation) in the Western Canada Basin, cut into a number of blocks of appropriate size in the vertical bedding direction, and use argon ion polishing technology to polish the sample after mechanical grinding. The surface was etched, and the development of organic pores in the mud shale block was observed by field emission scanning electron microscope.

[0045] Step 2: Taking the actual burial evolution history of the Silurian Longmaxi Formation in Well Jiaoye 1 in southeastern Sichuan as a geological constraint, determine the burial depth, static rock pressure and formation fluid pressure value at the time of evolution (Ro) corresponding to the simulated temperature ( Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com