Hydraulic mechanism oil level monitoring device

A technology of hydraulic mechanism and monitoring device, applied in the direction of measuring device, fluid pressure actuating device, lubrication indicating device, etc., can solve problems such as failure to ensure timely discovery or elimination of hydraulic mechanism, threat to power grid safety, circuit breaker refusal to operate, etc. Improve security and stability, simplify cumbersome procedures, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

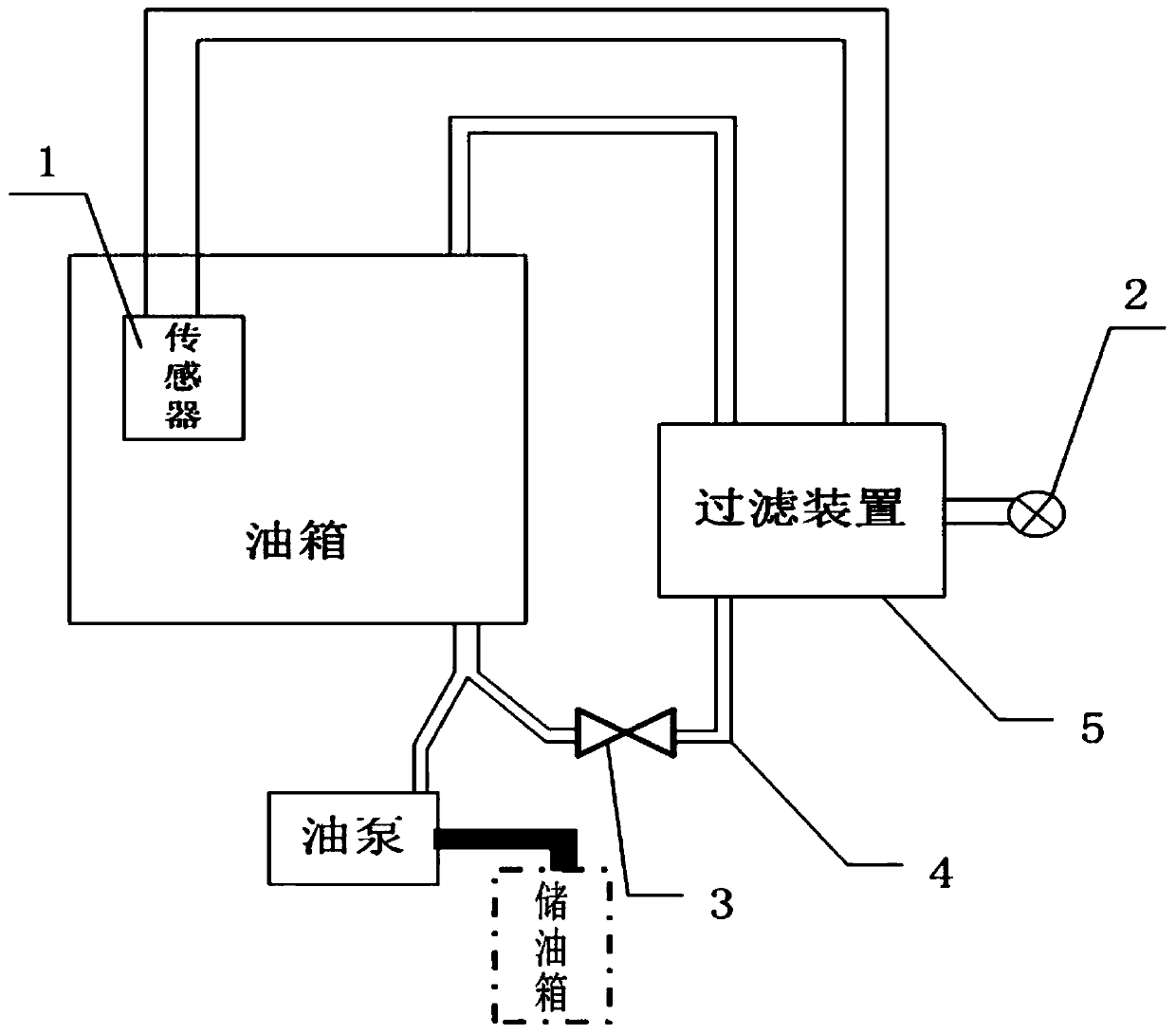

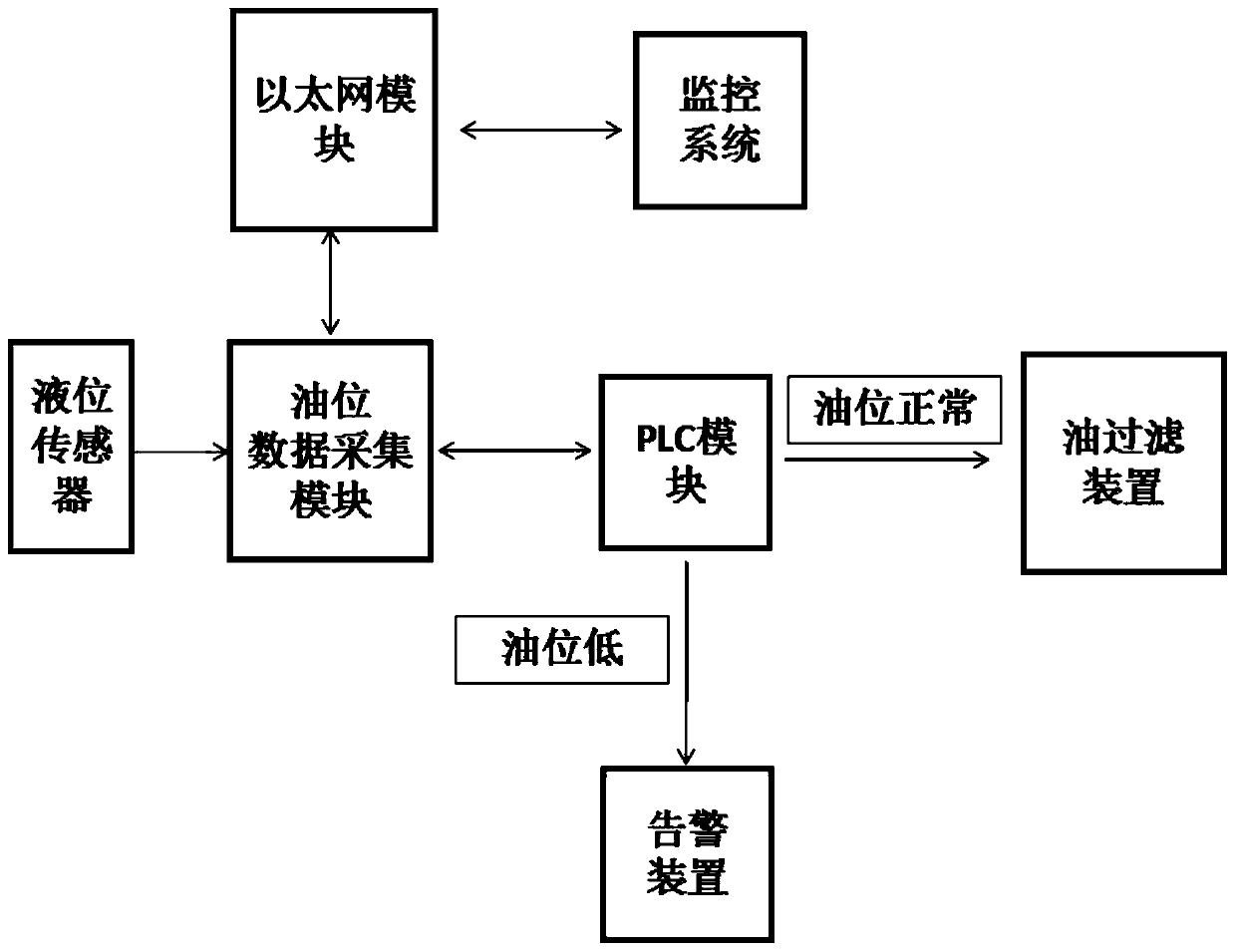

[0025] Such as Figure 1~2 As shown, it shows a specific embodiment of the present invention. A hydraulic system oil level monitoring device is used to monitor and filter the oil in the oil tank of the hydraulic system; the present invention includes an oil level sensor 1 for detecting and feeding back liquid level information. , The indicator light 2 used for alarm when the oil level drops, the one-way check valve 3 used to pass the filter assembly and the oil tank, the pipeline 4 used to connect each oil path, the filter assembly 5 used to filter the impurity oil ;

[0026] The oil level sensor is fixed on the inner wall of the oil tank, and outputs a linear resistance of 0 to 190 ohms according to the oil level;

[0027] It also includes an analog-to-digital conversion unit. The analog-to-digital conversion unit includes a voltage divider circuit and an analog-to-digital converter. The analog-to-digital conversion unit converts the resistance output by the oil level sensor into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com