Air suspension agent for fracturing proppant and construction method thereof

A fracturing proppant and air suspension technology, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of large damage to low layers, large amount of polymer, and clogged formations, etc., to achieve good sand suspension effect, Low consumption and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Suspension aid PAAAD can be prepared by controlled living free radical polymerization, and the preparation steps are as follows:

[0044] (1) Add 100ml of methanol to the flask and place it in an ice bath, then add methyl 2-bromopropionate MBP (10g, 60mmol) until completely dissolved; then slowly add potassium ethyl xanthate PEX (10.6g, 66mmol) , after PEX is completely dissolved, stir the reaction at room temperature for 24h, then vacuum filter to filter off KBr, use a mixture of ether and hexane 200ml (volume ratio 1:1) to extract the product from the filtrate, and the extract is washed with deionized water for several After drying with sodium sulfate and rotary evaporation, a yellow liquid X1 was obtained.

[0045] (2) Dissolve yellow liquid X1 (2.0g, 9.6mmol) in 7.1g ethanol in a round bottom flask, then add acrylamide AM (6.8g, 96.0mmol) and initiator V-50 (111mg, 0.41mmol) ) and distilled water (5.5ml), blowing argon for 30 minutes to deoxygenate under stirring, ...

Embodiment 2

[0048] The proppant is 20-40 mesh quartz sand.

[0049] The preparation method of the air suspension is as follows: 65g of 3# white oil, 5g of n-heptanol, 15g of terpineol oil, 15g of N-dimethyloctadecylbutyl diquaternary ammonium salt, 1g of suspension auxiliary agent PAAAD, and the above-mentioned composition After mixing the parts, stir evenly, and add an appropriate amount of hydrochloric acid or glacial acetic acid to neutralize the pH to 7 to obtain an air suspension agent for use. Wherein, N-dimethyl octadecyl butyl bis-quaternary ammonium salt structural formula is as follows:

[0050]

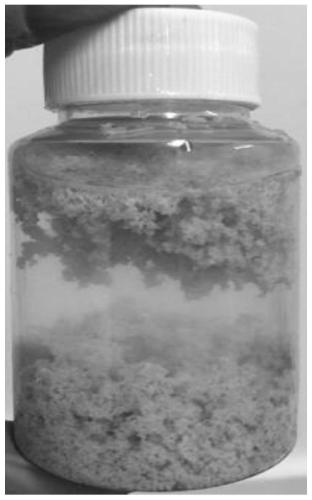

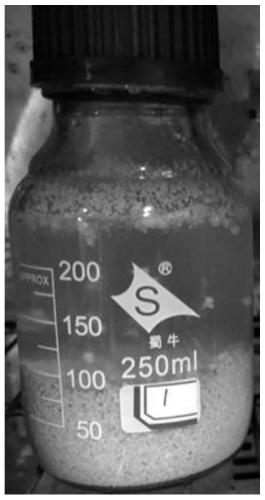

[0051] The preparation method steps of air-suspension proppant for fracturing: take 1000g of proppant quartz sand and lay it flat, spray 3g of air-suspension agent evenly on the surface of the quartz sand with a small air atomizing nozzle, and set it aside.

[0052] Preparation of slick water: Prepare 1L of water in a container, stir with high-speed machinery, slowly add 0.5g of co...

Embodiment 3

[0055] The proppant is 40-70 mesh quartz sand.

[0056] The preparation method of the air suspension is as follows: 65g of D100 solvent oil, 3g of n-octanol, 17g of pine alcohol oil, 6g of N,N-dimethyloctadecylbutyl bisquaternary ammonium salt, 9g of quaternary ammonium salt, and PAAAD, a suspension aid The dosage is 0.8g, the above components are mixed and stirred evenly, and an appropriate amount of hydrochloric acid or glacial acetic acid is added to neutralize the pH to 7 to obtain an air suspension, which is ready for use. Wherein, the structural formula of quaternary ammonium salt A is as follows:

[0057]

[0058] The preparation method steps of air-suspension proppant for fracturing: take 1000g of proppant quartz sand and lay it flat, spray 3g of air-suspension agent evenly on the surface of the quartz sand with a small air atomizing nozzle, and set it aside.

[0059] Preparation of slick water: Prepare 1L of water in a container, stir with high-speed machinery, sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com