Regeneration and recovery method of waste SCR denitration catalyst

A technology for denitrification catalysts and regeneration solutions, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of comprehensive recycling of unused SCR denitrification catalysts, unfavorable multiple regenerations, and poor regeneration capabilities and other problems, to achieve the effect of improving mechanical strength, solving poor regeneration ability, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

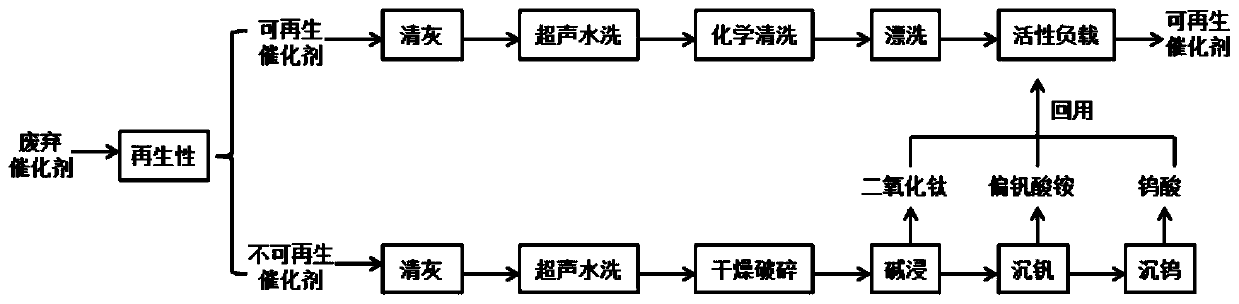

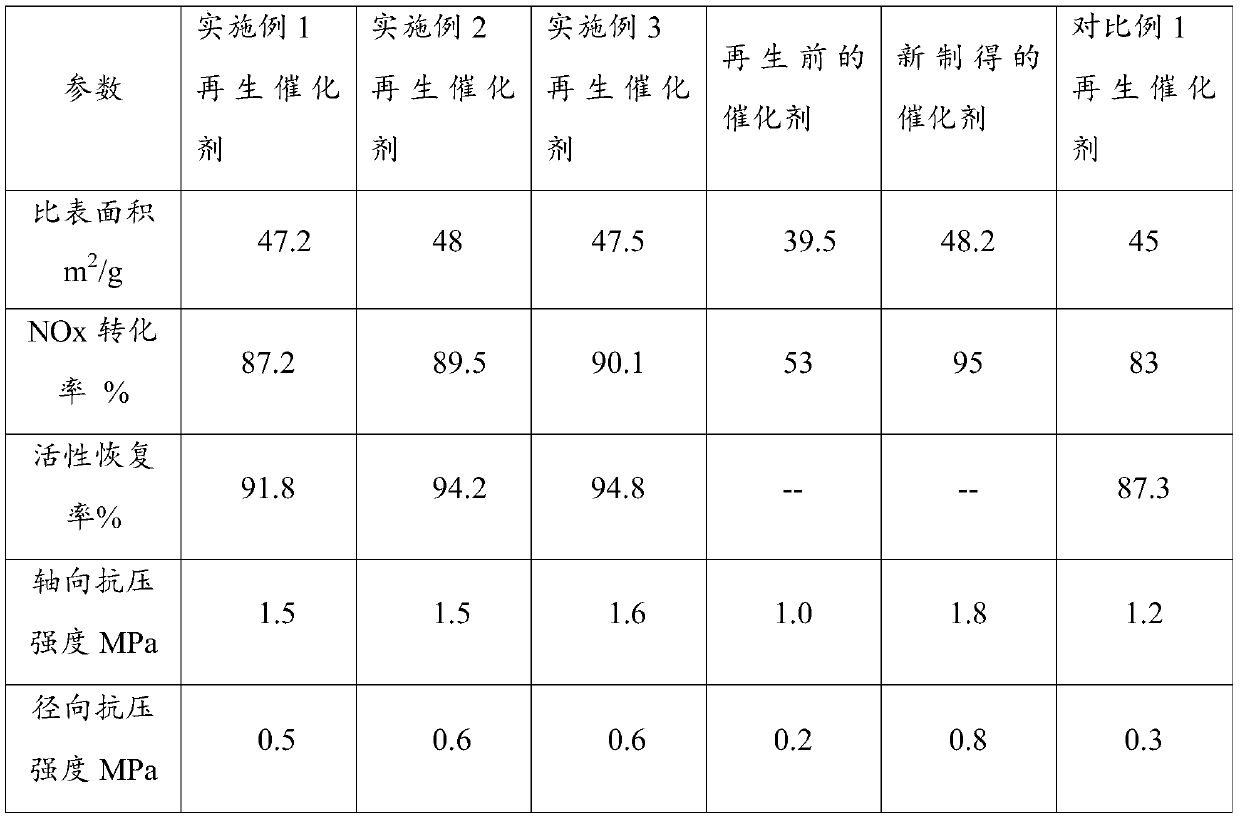

[0058] This embodiment provides a method for the regeneration and recovery of a waste SCR denitration catalyst, such as figure 1 As shown, it specifically includes the following steps:

[0059] Step 1: Judging the regeneration performance of the waste SCR denitration catalyst

[0060] a. Appearance requirements: the average wear depth of the windward end of the honeycomb waste SCR denitrification catalyst is not more than 30mm; the number of penetrating holes is not more than 5; the wear rate of the non-windward end is ≤0.3%;

[0061] b. Physical and chemical properties: axial compressive strength ≥ 1MPa, radial compressive strength ≥ 0.2MPa, specific surface area (BET) ≥ 30m 2 / g;

[0062] Those that meet the above requirements are reversible deactivation SCR denitration catalysts, and those that do not meet the above requirements are irreversible deactivation SCR denitration catalysts.

[0063] Step 2: Preprocessing

[0064] The surface of the reversible deactivation and...

Embodiment 2

[0074] This embodiment provides a method for the regeneration and recovery of a waste SCR denitration catalyst, such as figure 1 As shown, it specifically includes the following steps:

[0075] Step 1: Judging the regeneration performance of the waste SCR denitration catalyst

[0076] a. Appearance requirements: the average wear depth of the windward end of the honeycomb waste SCR denitrification catalyst is not more than 30mm; the number of penetrating holes is not more than 5; the wear rate of the non-windward end is ≤0.3%;

[0077] b. Physical and chemical properties: axial compressive strength ≥ 1MPa, radial compressive strength ≥ 0.2MPa, specific surface area (BET) ≥ 30m2 / g;

[0078] Those that meet the above requirements are reversible deactivation SCR denitration catalysts, and those that do not meet the above requirements are irreversible deactivation SCR denitration catalysts.

[0079] Step 2: Preprocessing

[0080] The surface of reversible deactivation and irreve...

Embodiment 3

[0090] This embodiment provides a method for the regeneration and recovery of a waste SCR denitration catalyst, such as figure 1 As shown, it specifically includes the following steps:

[0091] Step 1: Judging the regeneration performance of the waste SCR denitration catalyst

[0092] a. Appearance requirements: the average wear depth of the windward end of the honeycomb waste SCR denitrification catalyst is not more than 30mm; the number of penetrating holes is not more than 5; the wear rate of the non-windward end is ≤0.3%;

[0093] b. Physical and chemical properties: axial compressive strength ≥ 1MPa, radial compressive strength ≥ 0.2MPa, specific surface area (BET) ≥ 30m2 / g;

[0094] Those that meet the above requirements are reversible deactivation SCR denitration catalysts, and those that do not meet the above requirements are irreversible deactivation SCR denitration catalysts.

[0095] Step 2: Preprocessing

[0096] The surface of the reversible deactivation and ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average depth | aaaaa | aaaaa |

| Axial compressive strength | aaaaa | aaaaa |

| Radial compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com