Preparation method of glycosylated glutenin

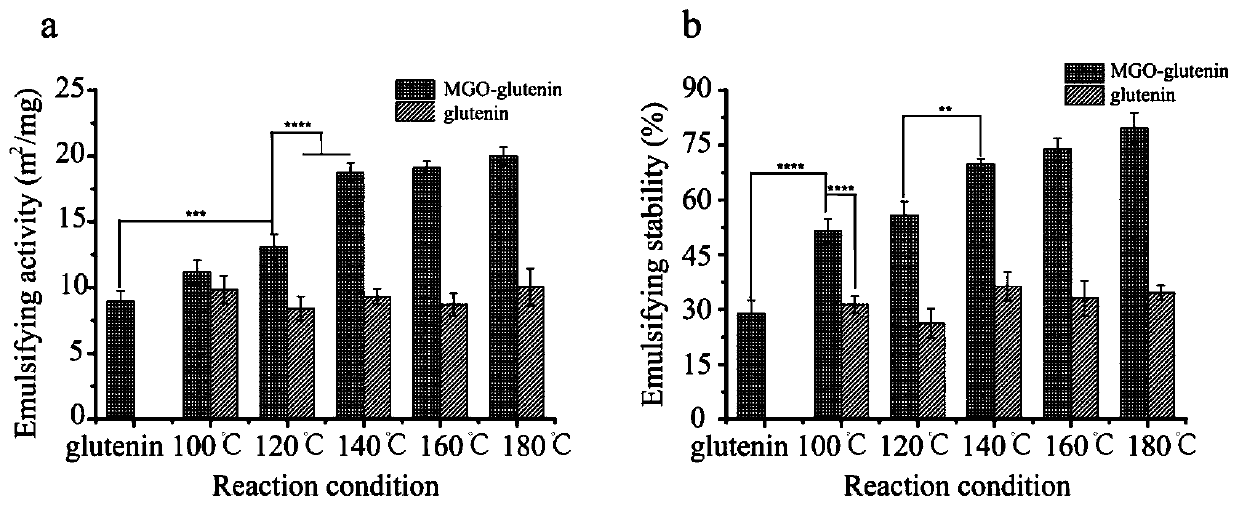

A technology of glutenin and glycosylation, which is applied in the field of preparation of glycosylated glutenin, can solve problems such as the functional properties of proteins in glycosylated modified wheat that few people have studied, and achieve extended food shelf life, improved solubility, and improved operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The wheat is made into dry powder with an ultrafine pulverizer, and passed through an 80-mesh sieve to obtain semolina. The starch in the wheat flour was removed by washing 20 times with the Martin method, and the gluten protein was obtained by freeze-drying. Add n-hexane at a material-to-liquid ratio of 1:10 (w / v), stir evenly to form a suspension, and place it in a fume hood for 18 hours to remove fat. The obtained defatted gluten protein, according to the solid-liquid ratio of 1:10 (w / v), add 0.6mol / L NaCl solution, stir at room temperature for 1h, then centrifuge the suspension at 10000g for 20min, collect the precipitate, repeat three times, Get precipitation 1. Distilled water was added to Precipitation 1 at a solid-to-liquid ratio of 1:10 (w / v), stirred at room temperature for 1 h to remove NaCl, and then the suspension was centrifuged at 10,000 g for 20 min to collect the precipitate and repeated three times to obtain Precipitation 2. Add 90% ethanol to the pr...

Embodiment 2

[0037]The wheat is made into dry powder with an ultrafine pulverizer, and passed through a 100-mesh sieve to obtain semolina. The starch in the wheat flour was removed by washing 20 times with the Martin method, and the gluten protein was obtained by freeze-drying. Add n-hexane at a material-to-liquid ratio of 1:10 (w / v), stir evenly to form a suspension, and place it in a fume hood for 18 hours to remove fat. The obtained defatted gluten protein was added into 0.6mol / L NaCl solution according to the solid-liquid ratio of 1:10 (w / v), stirred at room temperature for 2h, then the suspension was centrifuged at 10000g for 20min, the precipitate was collected, and repeated three times, Get precipitation 1. Distilled water was added to Precipitation 1 at a solid-to-liquid ratio of 1:10 (w / v), stirred at room temperature for 2 h to remove NaCl, and then the suspension was centrifuged at 10,000 g for 20 min to collect the precipitate and repeated three times to obtain Precipitation 2...

Embodiment 3

[0039] The wheat is made into dry powder with a superfine pulverizer, and passed through a 90-mesh sieve to obtain semolina. The starch in the wheat flour was removed by washing 20 times with the Martin method, and the gluten protein was obtained by freeze-drying. Add n-hexane at a material-to-liquid ratio of 1:15 (w / v), stir evenly to form a suspension, and place it in a fume hood for 32 hours to remove fat. The fat-free gluten protein that obtains, adds 0.6mol / L NaCl solution according to the solid-liquid ratio of 1:15 (w / v), stirs 2h at room temperature, then centrifuges the suspension at 9500g for 25min, collects the precipitate, repeats three times, Get precipitation 1. Distilled water was added to Precipitation 1 at a solid-to-liquid ratio of 1:15 (w / v), stirred at room temperature for 2 h to remove NaCl, and then the suspension was centrifuged at 9500 g for 25 min to collect the precipitate and repeated three times to obtain Precipitation 2. Add 80% ethanol to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com