A compact flangeless waveguide connection structure and design method

A connection structure without flange technology, applied in the microwave field, can solve the problems of low mechanical stability of the direct butt welding structure, which is not conducive to the overall design and flexible layout of the system, and the electromagnetic transmission performance is difficult to predict and guarantee. Miniaturization and flexible layout, reliable electromagnetic transmission performance, and the effect of avoiding electromagnetic leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

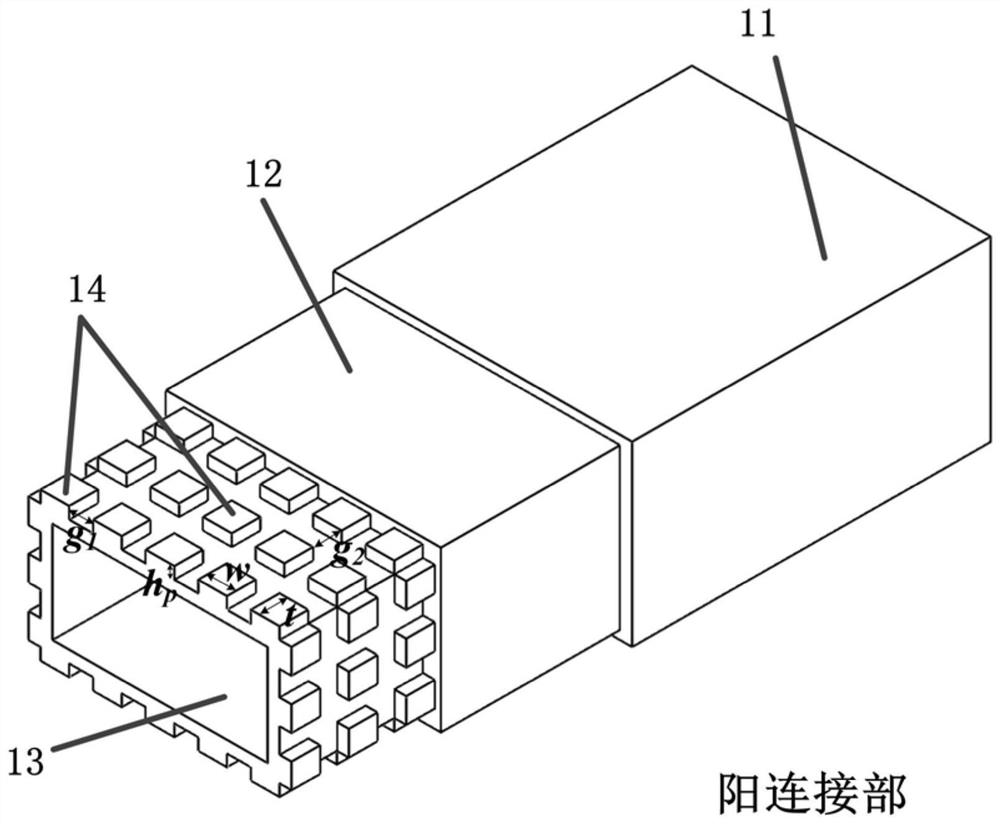

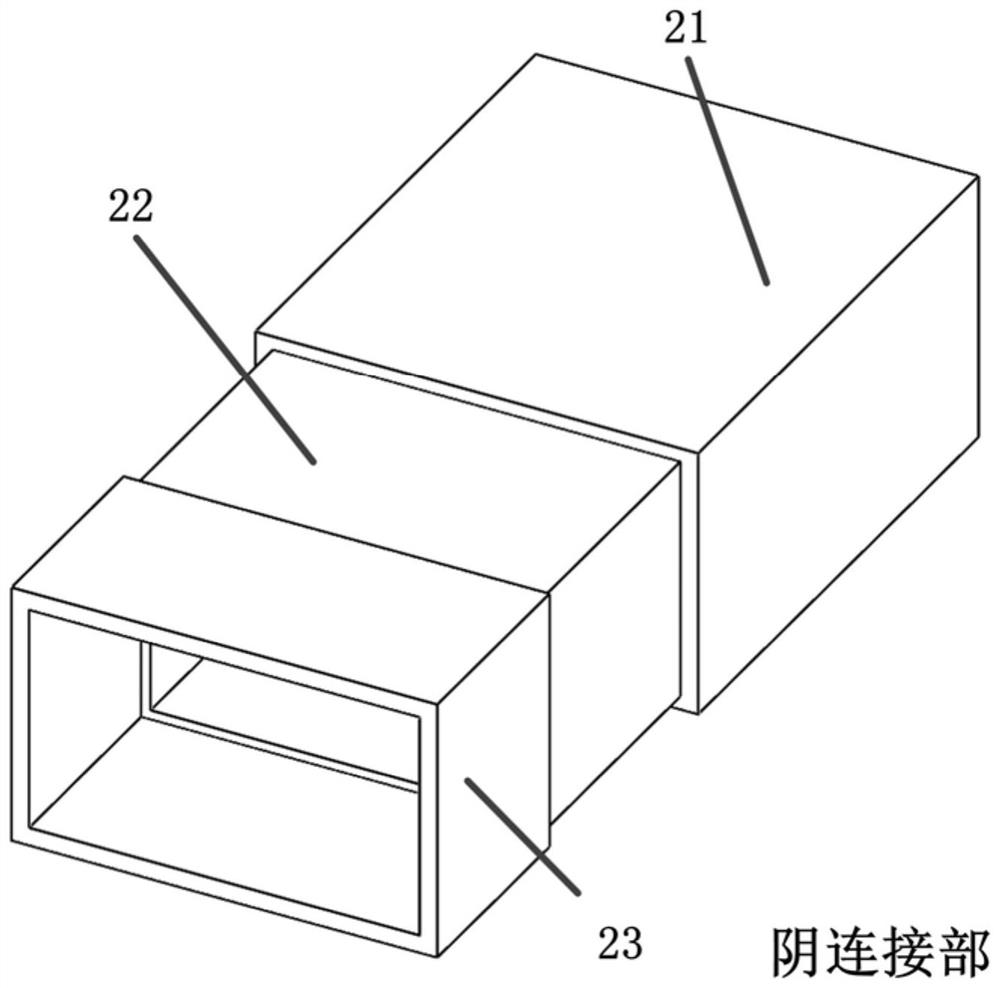

[0066] Taking the realization of the compact flangeless connection of the Ku-band BJ120 (WR75) waveguide (working bandwidth 9.84GHz to 15GHz) as an example, the specific implementation process of the present invention will be described:

[0067] (1) Determine the structural dimensions of the first impedance transformation section 12, the first non-standard waveguide section 13 and the second impedance transformation section 22 by the stepped impedance transformation method. Here, the first-order stepped impedance transformation method is selected, and the electrical simulation is performed by an electromagnetic simulation program. Transmission performance, working bandwidth covers the entire BJ120 waveguide working bandwidth.

[0068] (2) In the electromagnetic simulation program, a simulation model of a single metal convex body in the periodic metal convex body array 14 is established, such as: Figure 5 As shown, the height of each metal protrusion in the periodic metal prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com